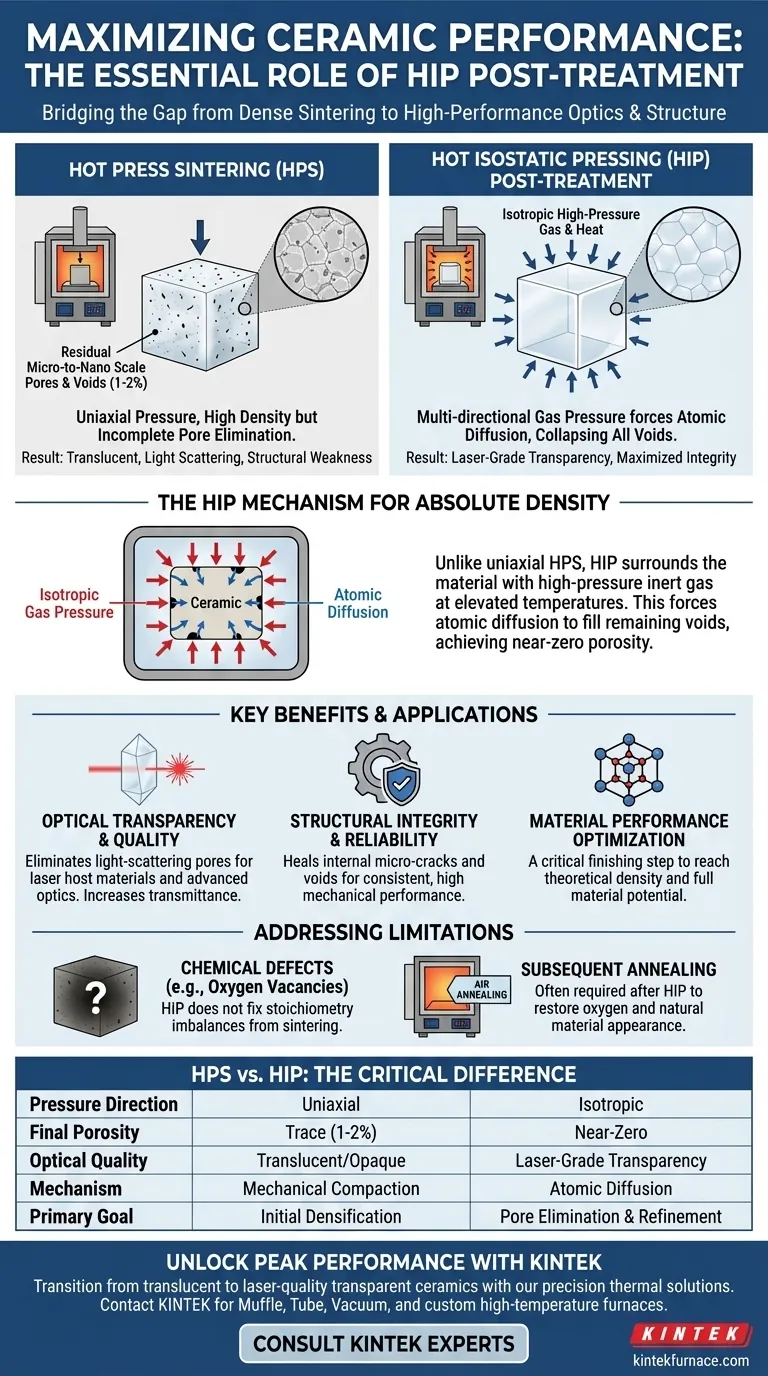

Post-treatment in a Hot Isostatic Pressing (HIP) furnace is essential because standard hot press sintering cannot eliminate the final traces of internal porosity. While hot pressing achieves high theoretical density, it often leaves behind micro-to-nano scale closed pores that act as scattering centers for light. HIP uses isotropic high-pressure gas to provide the necessary driving force to collapse these residual defects, which is a prerequisite for achieving the optical transparency required for high-performance laser applications.

Even at high densities, residual microscopic voids prevent ceramics from reaching their full optical potential. HIP post-treatment serves as the definitive refining step, utilizing multi-directional pressure to eliminate these voids and maximize material performance.

The Persistence of Microscopic Voids

Why Hot Pressing Falls Short

Hot press sintering typically applies pressure in a single axis, which can reach high density but struggles to close the final 1-2% of porosity. These remaining "closed pores" are trapped within the grain structure and require significantly higher, more uniform forces to be removed.

The Impact on Short-Wavelength Transmittance

Residual pores, even at the nanoscale, are large enough to scatter light, particularly at shorter wavelengths. For transparent ceramics and laser host materials, this scattering results in a loss of transmittance and a significant reduction in efficiency.

The HIP Mechanism for Absolute Density

Isotropic Gas Pressure as a Driving Force

Unlike uniaxial pressing, a HIP furnace surrounds the material with high-pressure inert gas at elevated temperatures. This isotropic pressure acts equally from all directions, forcing the diffusion of atoms into the remaining void spaces.

Optimizing Laser and Optical Quality

By eliminating the final micro-to-nano scale pores, HIP drastically improves the optical homogeneity of the ceramic. This process is often the difference between a material that is merely translucent and one that is laser-quality transparent.

Understanding the Trade-offs and Limitations

Addressing Chemical Defects

While HIP is superior for densification, it does not always address chemical imbalances. Sintering in a vacuum or reducing environment can create oxygen vacancies, which cause a dark appearance in materials like Yttrium Oxide.

The Need for Subsequent Annealing

HIP focuses on physical structure (density), but an additional air-atmosphere annealing step is often required afterward. This restores the lattice stoichiometry and removes the dark tint caused by oxygen loss during the high-temperature sintering phases.

Operational Complexity

HIP is a high-cost, high-complexity process compared to standard sintering. It requires specialized equipment capable of handling both extreme pressures and temperatures, making it a "finishing" step rather than a primary shaping method.

Applying HIP to Your Ceramic Project

Achieving the highest possible performance requires matching the post-treatment to your material's specific failure points.

- If your primary focus is maximum optical transparency: Use HIP post-treatment to ensure all micro-to-nano scale pores are eliminated, as even trace porosity will scatter light.

- If your primary focus is structural integrity: HIP can be used to heal internal micro-cracks and voids, significantly increasing the consistency and mechanical reliability of the ceramic.

- If your primary focus is color or lattice stoichiometry: Follow the HIP process with an oxygen-rich air annealing step to eliminate oxygen vacancies and restore the material's natural appearance.

HIP post-treatment is the critical bridge between a dense ceramic and a high-performance optical material.

Summary Table:

| Feature | Hot Press Sintering | HIP Post-Treatment |

|---|---|---|

| Pressure Direction | Uniaxial (Single-axis) | Isotropic (Multi-directional) |

| Final Porosity | Trace residual pores (1-2%) | Near-zero theoretical density |

| Optical Quality | Translucent to Opaque | Laser-grade Transparency |

| Mechanism | Mechanical compaction | Atomic diffusion via gas pressure |

| Primary Goal | Initial densification | Pore elimination & refinement |

Unlock Peak Material Performance with KINTEK

Transition from translucent to laser-quality transparent ceramics with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature furnaces designed to meet your most demanding densification needs.

Whether you are refining advanced ceramics for optics or enhancing structural integrity for industrial applications, our engineering team is ready to help you customize the perfect system for your unique laboratory or production requirements.

Ready to eliminate porosity and maximize material efficiency? Contact KINTEK Today to Consult Our Experts

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are vacuum furnaces particularly suitable for high temperature sintering? Ensure Purity and Precision for Superior Results

- What is the function of a vacuum drying oven in processing mixed TiB2-SiC slurries? Protect Material Integrity

- Why is a high vacuum box sintering furnace required for B4C/Al composites? Unlock Peak Composite Performance

- What is the primary function of a vacuum high-temperature furnace in the synthesis of Mg3Sb2 thermoelectric materials?

- What advantages does laser active brazing offer compared to traditional furnace brazing? Precision Sealing Explored

- Why is dual monitoring used for Tantalum annealing? Achieve 20K Precision in Vacuum Furnaces

- Why are the materials used in vacuum furnace construction critical? Ensure Peak Performance and Purity

- Why is a vacuum oven required for FeZn-MOFs@Al2O3? Preserve Structure and Activity