Vacuum furnaces are particularly suitable for high-temperature sintering because they provide an exceptionally clean, controllable, and uniform heating environment. This prevents oxidation and contamination of sensitive materials, ensuring the resulting parts have superior structural integrity and purity, a feat that is difficult to achieve in conventional atmospheric furnaces.

Sintering at high temperatures makes materials highly reactive to atmospheric gases like oxygen, which can ruin the final product. A vacuum furnace's core advantage is its ability to remove this atmosphere, creating a pristine environment that enables precise control over the entire thermal process.

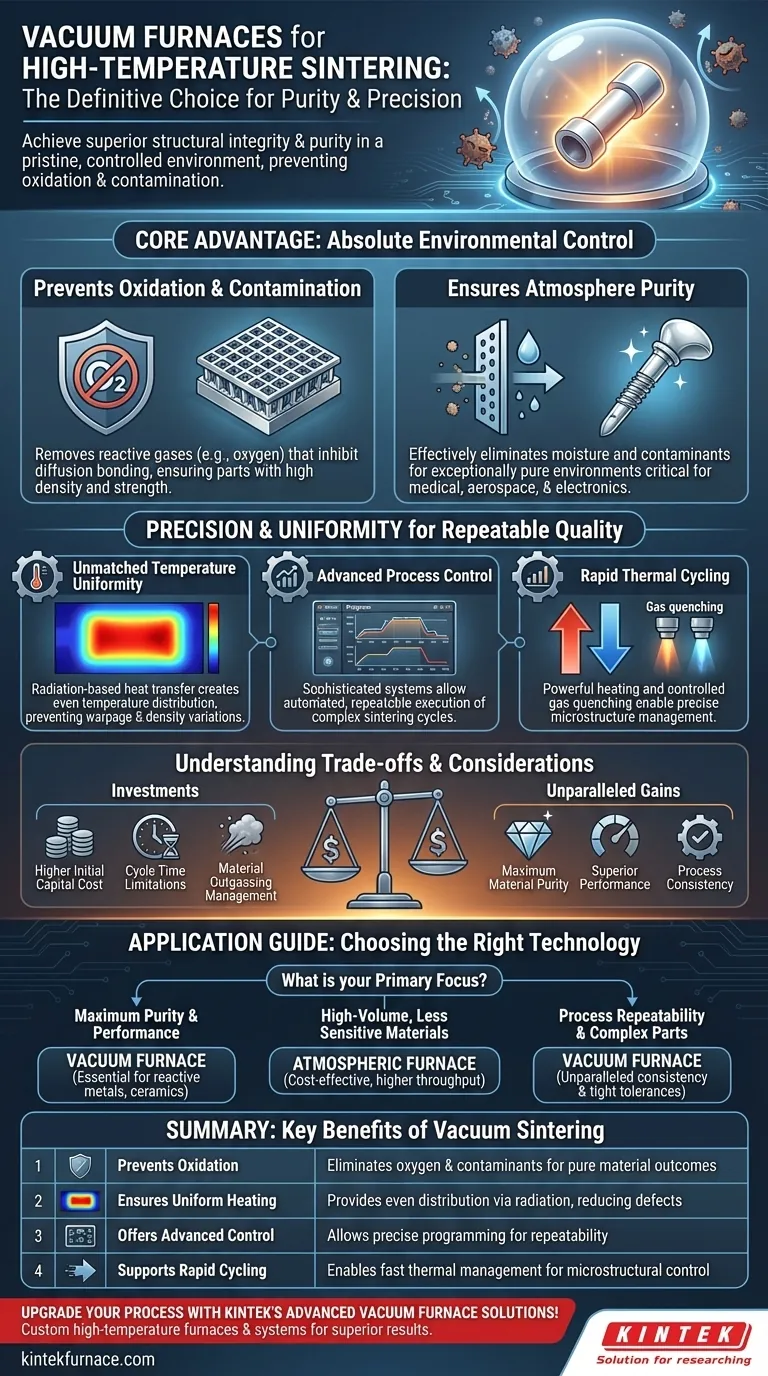

The Core Advantage: Absolute Environmental Control

The primary reason vacuum technology is paired with high-temperature sintering is its ability to create a chemically inert environment. This fundamentally changes what is possible during the process.

Preventing Oxidation and Contamination

At elevated temperatures, most metals and many ceramics become highly susceptible to oxidation. The presence of oxygen, even in trace amounts, can form undesirable oxide layers on the powder particles.

These layers inhibit the diffusion bonding that is central to sintering, resulting in parts with poor density, reduced strength, and compromised material properties. A vacuum furnace removes a vast majority of the oxygen and other reactive gases, protecting the material's integrity.

Ensuring Atmosphere Purity

Beyond just oxygen, a vacuum effectively removes moisture and other volatile contaminants that may be present in the furnace chamber or outgas from the parts themselves. This ensures the sintering process occurs in an exceptionally pure environment, which is critical for medical, aerospace, and electronics applications where material purity is non-negotiable.

Precision and Uniformity for Repeatable Quality

Control is the second pillar of a vacuum furnace's superiority. The ability to dictate and maintain exact conditions throughout the cycle ensures consistent results from batch to batch.

Unmatched Temperature Uniformity

The vacuum environment aids in creating extremely uniform temperature distribution. Without air currents to create hot and cold spots, heat is transferred primarily through radiation, which provides even heating across the entire workload. This ensures every part, and every section of a part, sinters consistently, preventing warpage and density variations.

Advanced Process Control

Modern vacuum furnaces are equipped with sophisticated control systems. These allow for multi-stage programming of temperature, heating/cooling rates, and vacuum levels. This high degree of automation and control enables complex sintering cycles to be executed with perfect repeatability, a key requirement for industrial production.

Rapid Heating and Cooling

Many high-temperature vacuum furnaces are designed for rapid thermal cycling. The combination of powerful heating elements and controlled gas quenching (using inert gases like Argon or Nitrogen) allows operators to precisely manage the material's microstructure by controlling the heating and cooling rates, further refining its final properties.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnaces are not the universal solution for all sintering needs. Understanding their limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces and their associated pumping systems represent a significantly higher capital cost compared to standard atmospheric furnaces. The complexity and precision engineering required drive up the price.

Cycle Time Limitations

Achieving a deep vacuum takes time. The pump-down phase can add considerable time to the overall process cycle, which may impact throughput for high-volume, low-margin parts where speed is the primary driver.

Material Outgassing

Certain materials or binding agents can release significant amounts of gas when heated under vacuum (a process known as outgassing). This can contaminate the furnace and make it difficult to maintain the desired vacuum level, requiring careful material selection and process design.

How to Apply This to Your Project

Your choice of furnace technology should be directly tied to the requirements of your final product.

- If your primary focus is maximum material purity and performance: A vacuum furnace is the definitive choice. It is essential for reactive metals like titanium, refractory metals, and high-performance ceramics.

- If your primary focus is high-volume production of less sensitive materials: An atmospheric furnace (like a continuous belt furnace) may offer a more cost-effective solution with higher throughput.

- If your primary focus is process repeatability for complex parts: The precise thermal and atmospheric control of a vacuum furnace provides unparalleled consistency for components with tight tolerances.

Ultimately, selecting a vacuum furnace is an investment in process control, ensuring the highest possible quality for the most demanding applications.

Summary Table:

| Feature | Benefit |

|---|---|

| Prevents Oxidation | Eliminates oxygen and contaminants for pure material outcomes |

| Ensures Uniform Heating | Provides even temperature distribution via radiation, reducing defects |

| Offers Advanced Control | Allows precise programming of temperature and vacuum for repeatability |

| Supports Rapid Cycling | Enables fast heating/cooling with gas quenching for microstructural control |

Upgrade your sintering process with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Achieve superior purity, precision, and performance—contact us today to discuss how we can enhance your results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing