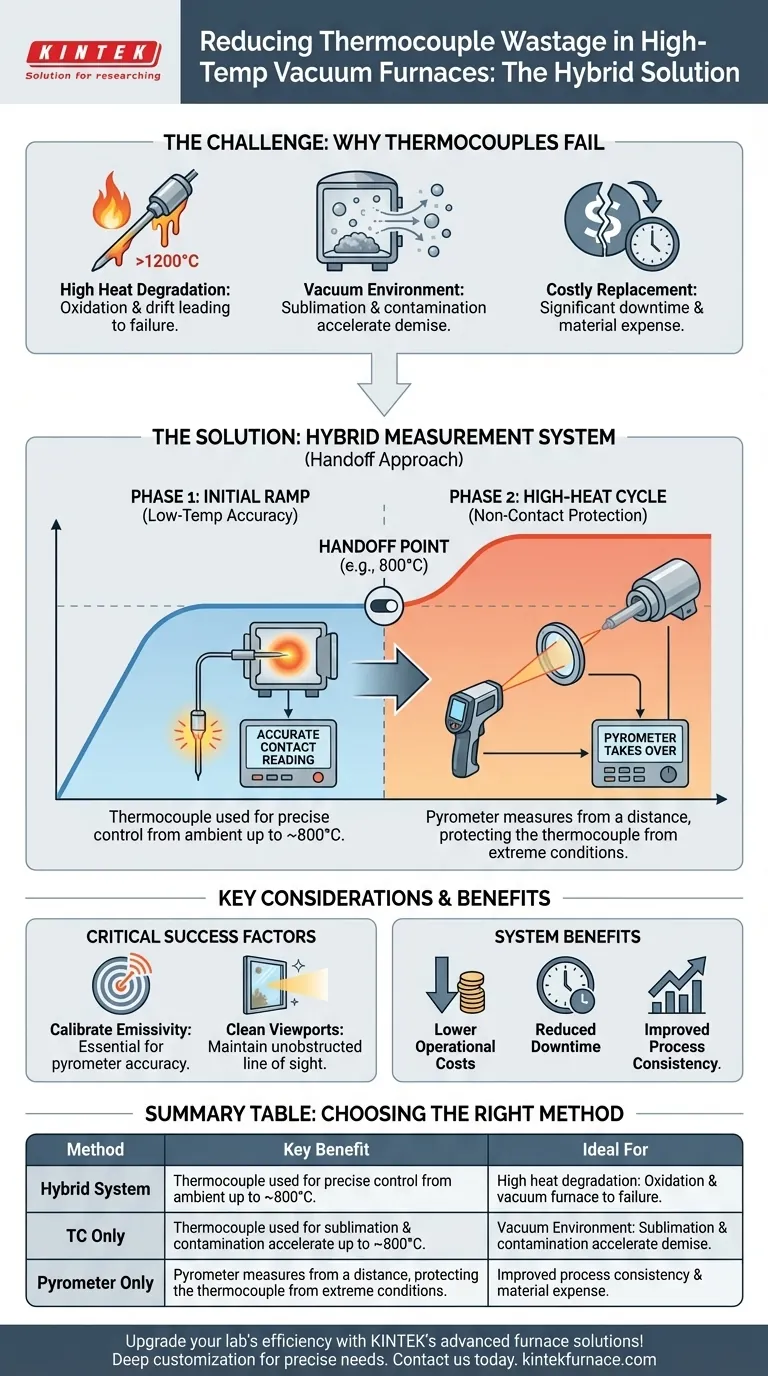

To reduce thermocouple wastage in high-temperature vacuum furnaces, the standard industry practice is to use a hybrid temperature measurement system. A traditional thermocouple is used for accuracy at lower temperatures, and a non-contact optical pyrometer takes over measurement duties for the high-temperature phases of the cycle. This "handoff" approach dramatically extends the life of the thermocouple by protecting it from the extreme conditions that cause rapid degradation and failure.

The core strategy to reduce thermocouple wastage involves supplementing, not replacing, the thermocouple. A thermocouple provides essential accuracy during the initial heating ramp, after which an optical pyrometer takes over, allowing the fragile thermocouple to be either retracted or simply ignored by the control system during the most damaging high-temperature stages.

The Fundamental Challenge: Why Thermocouples Fail

Thermocouples are essential for precise temperature control, but their physical nature makes them inherently vulnerable in extreme environments. Understanding why they fail is key to developing a solution.

The Impact of High Temperatures

Thermocouples work by joining two dissimilar metals. At sustained high temperatures (typically above 1200°C), these metals begin to degrade. Processes like oxidation, grain growth, and element migration cause the thermocouple's voltage output to "drift," leading to inaccurate readings and eventual mechanical failure.

The Vacuum Environment

The vacuum itself introduces challenges. Certain metals used in thermocouples can sublimate (turn from a solid directly to a gas) under a combination of high heat and low pressure. This process, along with outgassing, contaminates both the furnace environment and the thermocouple itself, accelerating its demise.

The Inevitable Cost of Replacement

Constant failure results in significant operational costs. This includes not only the material cost of the thermocouples (especially expensive noble-metal types like S, R, or B) but also the furnace downtime and labor required for replacement.

The Solution: A Hybrid Measurement System

The most effective and widely adopted solution is not to find a "better" thermocouple, but to limit its exposure to the harshest conditions. This is achieved with a dual-sensor system.

The Role of the Thermocouple

The thermocouple remains the sensor of choice for the initial phase of the furnace cycle. It provides highly accurate, direct-contact temperature measurement from ambient up to a moderate temperature (e.g., 800°C), where its stability and reliability are excellent.

The Role of the Pyrometer

A pyrometer is an optical instrument that measures an object's temperature from a distance by detecting its thermal radiation. Because it has no physical contact with the hot zone, it is not subject to the degradation that destroys thermocouples.

How the "Handoff" Works

The furnace control system is programmed with a specific handoff temperature.

- Low-Temp Control: The system uses the thermocouple's reading for precise control during the initial ramp-up.

- Handoff Point: Once the furnace reaches the predetermined temperature, the control system switches its input source from the thermocouple to the pyrometer.

- High-Temp Control: The pyrometer provides the temperature reading for the rest of the high-heat cycle. The thermocouple may even be physically retracted from the hot zone by an actuator to protect it completely.

Understanding the Trade-offs and Considerations

While effective, this hybrid approach introduces its own set of technical considerations that must be managed.

Pyrometer Accuracy and Emissivity

A pyrometer's accuracy is critically dependent on a property called emissivity—the measure of an object's ability to emit thermal radiation. This value must be correctly configured in the control system for the specific material being heated. Incorrect emissivity settings are a common source of temperature error.

Line of Sight and Viewport Maintenance

Pyrometers require a clean, unobstructed line of sight to the target. Any dust, film, or coating on the furnace's glass viewport will absorb thermal radiation and cause the pyrometer to report a lower, inaccurate temperature. Regular viewport cleaning becomes a critical maintenance task.

Initial System Cost vs. Long-Term Savings

Implementing a system with a quality pyrometer, control logic, and potentially a thermocouple retraction mechanism has a higher upfront cost than a simple thermocouple-only setup. However, this initial investment is almost always recovered through reduced downtime, lower thermocouple consumption, and improved process consistency.

Making the Right Choice for Your Process

Your specific operational goal will determine how you implement and optimize this strategy.

- If your primary focus is maximum accuracy: Use a hybrid system and calibrate the pyrometer's emissivity by comparing its reading to the thermocouple's reading at the handoff temperature. This ensures a seamless and accurate transition.

- If your primary focus is minimizing operational costs: The pyrometer handoff system is the definitive solution. The long-term savings from reduced thermocouple replacement and furnace downtime will far outweigh the initial capital expense.

- If you operate at temperatures consistently below the degradation point of your thermocouple (e.g., under 1100°C for Type K): A pyrometer system may be an unnecessary expense. In this case, focus on using high-quality sheathed thermocouples and implementing a predictive maintenance schedule for replacement.

By strategically combining the strengths of both thermocouples and pyrometers, you achieve both the measurement precision and the operational robustness required for modern high-temperature applications.

Summary Table:

| Method | Key Benefit | Ideal For |

|---|---|---|

| Hybrid System (Thermocouple + Pyrometer) | Reduces thermocouple exposure to high heat, extending life | High-temperature processes above 1200°C |

| Thermocouple Only | High accuracy at lower temperatures | Processes consistently below 1100°C |

| Pyrometer Only | No physical contact, avoids degradation | Applications where emissivity is well-calibrated |

Upgrade your lab's efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions to meet your unique experimental needs, reducing thermocouple wastage and operational costs. Contact us today to discuss how we can enhance your processes and deliver reliable, cost-effective performance!

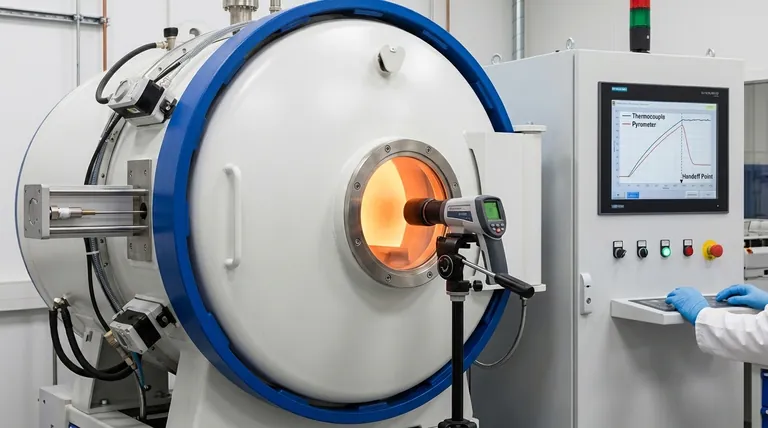

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision