At its core, the difference between a vacuum furnace and an air furnace is the atmosphere in which a material is heated. An air furnace (also called a conventional or atmospheric furnace) heats parts in the presence of ambient air. A vacuum furnace first removes the air and other gases from its chamber, creating a low-pressure, controlled environment before heating begins.

The choice between an air and vacuum furnace is not just a hardware decision; it is a fundamental choice about controlling the chemical environment. An air furnace is simpler, but a vacuum furnace provides ultimate control over surface chemistry, preventing unwanted reactions like oxidation.

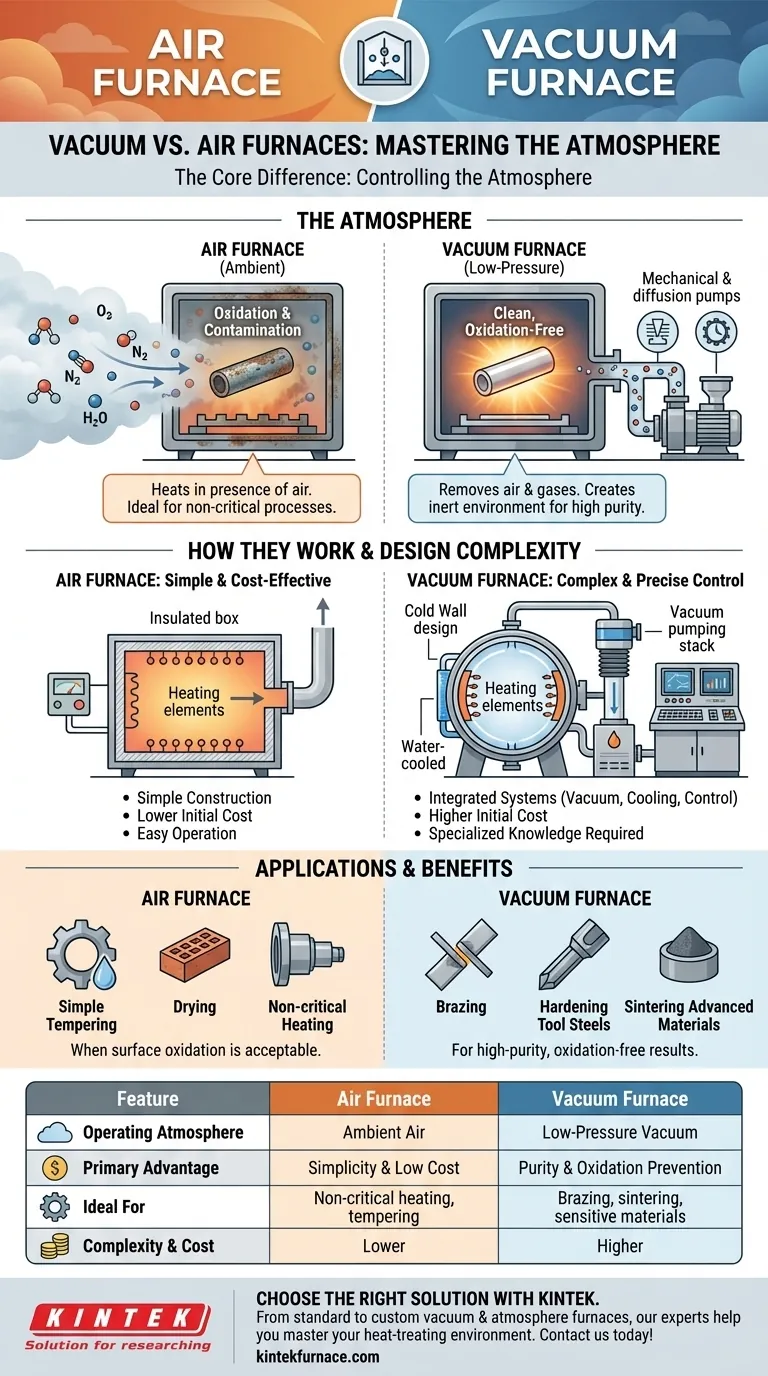

The Core Difference: Controlling the Atmosphere

The environment inside the furnace chamber directly dictates the outcome of the heat-treating process. The presence or absence of air is the single most important variable.

How an Air Furnace Works

An air furnace, often in a simple box or tube shape, heats materials using the surrounding atmospheric air as the medium. Its construction is straightforward, typically involving a heating chamber, heating elements, and a basic temperature controller.

These are common for processes where surface interaction with air is acceptable, non-critical, or even desired.

The Problem with Air: Oxidation and Contamination

When most metals are heated in the presence of oxygen, they undergo oxidation, forming a layer of scale or discoloration on the surface. Air also contains nitrogen and moisture, which can cause other unwanted surface reactions like decarburization (carbon loss in steel), leading to compromised material properties.

How a Vacuum Furnace Solves This

A vacuum furnace uses a system of pumps to evacuate nearly all the air from the sealed chamber before the heating cycle starts. By removing the reactive gases, it creates a chemically inert environment.

This prevents oxidation and other atmospheric contamination, ensuring the material's surface remains clean and bright throughout the process.

The Benefits of a Vacuum Environment

Operating in a vacuum provides significant advantages for sensitive materials and processes. Key benefits include high thermal efficiency, the prevention of oxidation and decarburization, and a surface purification effect as some surface impurities can vaporize in the vacuum.

Comparing Furnace Design and Complexity

The functional difference in atmosphere requires a significant difference in mechanical design and operational complexity.

The Simple Structure of an Air Furnace

An air furnace is mechanically simple. Whether it's a box furnace for larger parts or a tube furnace for smaller or continuous-flow samples, the design prioritizes heating efficiency in a non-sealed environment. They are generally easier to operate and maintain.

The Complex Systems of a Vacuum Furnace

A vacuum furnace is a far more complex machine. It integrates multiple sophisticated systems, including:

- A Vacuum System: A series of pumps (e.g., mechanical, diffusion) to create and maintain the low-pressure environment.

- A Sealed Heating Chamber: A robust, leak-proof vessel to hold the vacuum.

- An Advanced Heating System: Often using elements made of graphite or specialty metals designed to operate without air.

- A Precise Control System: To manage vacuum levels, temperature ramps, and cooling cycles.

Cold Wall vs. Hot Wall Designs

Within vacuum furnaces, designs vary further. Cold wall furnaces have a water-cooled outer shell, keeping it near room temperature while the interior reaches extreme heat. This allows for higher operating temperatures, faster cycling, and better temperature uniformity compared to older hot wall designs.

Understanding the Trade-offs

Choosing the correct furnace means balancing process requirements against cost and complexity.

When to Choose an Air Furnace

An air furnace is the right choice when process simplicity and low cost are paramount. It is perfectly suitable for applications where surface oxidation is not a concern, such as simple tempering, drying, or when a subsequent cleaning process will remove any surface scale.

The Cost of Control: Vacuum Furnace Drawbacks

The primary drawback of a vacuum furnace is its high initial cost and operational complexity. The vacuum pumps and sophisticated control systems require specialized knowledge for operation and maintenance, increasing the total cost of ownership.

A Note on Controlled Atmospheres

It is important to distinguish a vacuum from a "controlled atmosphere." A retort furnace, for example, uses a sealed chamber not to create a vacuum, but to introduce a specific process gas like nitrogen or argon. This provides a different kind of atmospheric control, used when a specific gas-phase reaction is desired.

Making the Right Choice for Your Application

Selecting the right furnace requires a clear understanding of your material, your process, and your desired outcome.

- If your primary focus is cost-effective, simple heating: An air furnace is the ideal choice, provided that surface oxidation is acceptable for your final product.

- If your primary focus is a high-purity, oxidation-free result: A vacuum furnace is non-negotiable for sensitive processes like brazing, hardening tool steels, or sintering advanced materials.

- If your primary focus is a specific gas-phase reaction: A retort or other controlled-atmosphere furnace is necessary to introduce a precise gas environment, which a vacuum furnace is not designed to do.

Ultimately, choosing the right furnace is about mastering the environment to achieve your desired material properties.

Summary Table:

| Feature | Air Furnace | Vacuum Furnace |

|---|---|---|

| Operating Atmosphere | Ambient Air | Low-Pressure Vacuum |

| Primary Advantage | Simplicity & Low Cost | Purity & Oxidation Prevention |

| Ideal For | Non-critical heating, tempering | Brazing, sintering, hardening sensitive materials |

| Complexity & Cost | Lower | Higher |

Unsure which furnace is right for your application?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, and our specialized Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let our experts help you master your heat-treating environment. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance