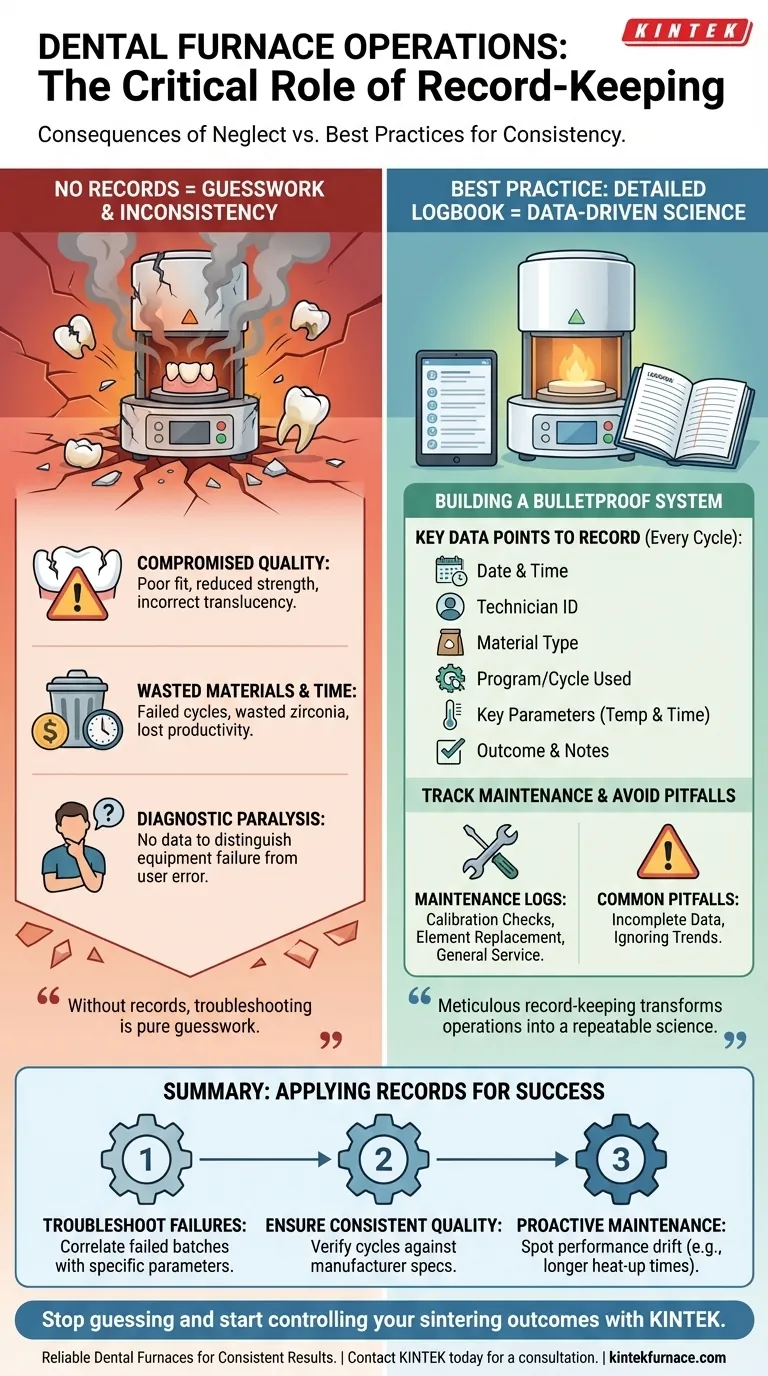

The short answer is this: Failing to keep records for your dental furnace leads directly to inconsistent sintering outcomes and makes troubleshooting failures a matter of pure guesswork. The best practice is to maintain a detailed logbook, either digital or physical, for every operational cycle.

Meticulous record-keeping is not an administrative burden; it is the fundamental quality control system that transforms your furnace operations from an unpredictable art into a repeatable, data-driven science.

The Hidden Costs of Poor Documentation

When a dental restoration fails, the immediate focus is often on the material or the preparation. However, the sintering process is a frequent and often invisible culprit. Without records, you have no way to diagnose or prevent recurring issues.

Compromised Restoration Quality

Inconsistent heating cycles, which are impossible to track without logs, can compromise the final physical properties of the ceramic. This can result in restorations with poor marginal fit, reduced strength, or incorrect translucency, leading to clinical failures and dissatisfied clients.

Wasted Materials and Time

Every failed sintering cycle means wasted zirconia, wasted energy, and, most importantly, wasted technician time. The cost of remakes extends far beyond materials; it damages lab productivity and profitability.

Diagnostic Paralysis

When a batch of crowns comes out chalky or distorted, where do you begin? Without a record of the temperature, timing, and specific cycle used, you cannot distinguish between a furnace malfunction, user error, or a faulty material. You are left with no data to analyze, forcing you to guess at the cause.

Building a Bulletproof Record-Keeping System

A robust logging process is simple to implement but requires discipline. It serves as your primary tool for ensuring quality, consistency, and traceability for every restoration that leaves your lab.

Key Data Points to Record

For every furnace cycle, your log should capture several essential data points.

- Date and Time: The exact start time of the cycle.

- Technician ID: Who operated the furnace.

- Material Type: The specific brand and type of zirconia or ceramic used.

- Program/Cycle Used: The name or number of the sintering program.

- Key Parameters: A confirmation of the target temperature settings and timings.

- Outcome/Notes: A brief note on the result (e.g., "Successful," "Slightly low translucency," "1 unit cracked").

Tracking Maintenance and Calibration

Your logbook should also be the central repository for all maintenance activities.

- Calibration Checks: Record the date and results of every temperature calibration test.

- Element Replacement: Note the date heating elements were inspected or replaced.

- General Service: Document any professional servicing or repairs.

Digital vs. Physical Logbooks

A physical, paper-based logbook is simple and effective. However, a digital spreadsheet or dedicated software offers powerful advantages, such as searchability and the ability to easily analyze performance data over time to spot developing issues.

Common Pitfalls to Avoid

Simply having a logbook is not enough. To be effective, the data must be accurate and consistently captured.

The Risk of Incomplete Data

A log with missing entries is almost as problematic as no log at all. It creates a false sense of security while leaving critical diagnostic gaps. A consistent process that is part of the standard workflow is essential.

Ignoring the Trends

The true power of a logbook is revealed over time. Periodically review your records to identify trends. Is one material consistently causing issues? Is the furnace taking longer to reach temperature? This analysis allows you to move from reactive problem-solving to proactive maintenance.

How to Apply This to Your Lab

Use your record-keeping strategy to target your lab's specific operational goals.

- If your primary focus is troubleshooting failures: Your logbook is the first place you should look to correlate a failed batch with the specific cycle parameters used.

- If your primary focus is ensuring consistent quality: Use your records as a verification tool to ensure every cycle runs precisely according to the material manufacturer's specifications.

- If your primary focus is proactive maintenance: Analyze your logs to spot performance drift, such as longer heat-up times, which can indicate aging elements that require service.

By implementing a rigorous documentation process, you gain complete control over one of the most critical stages of dental prosthesis fabrication.

Summary Table:

| Key Data Point | Why It Matters |

|---|---|

| Date, Time & Technician | Provides traceability and accountability for every cycle. |

| Material & Program Used | Ensures the correct sintering parameters are applied. |

| Target Parameters | Confirms the furnace operated as intended. |

| Cycle Outcome & Notes | Creates a history for diagnosing trends and failures. |

| Maintenance Logs | Tracks furnace health and calibration for proactive upkeep. |

Stop guessing and start controlling your sintering outcomes.

Inconsistent results and costly remakes are often a symptom of an undocumented process. Just as precise record-keeping is essential for your furnace, precision engineering is the foundation of the furnace itself.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our dental furnaces are designed for reliability and repeatability, giving you the stable platform you need to make your quality control system a success.

Let's discuss how a KINTEK furnace can bring unmatched consistency to your lab. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- How does precise temperature control in a porcelain furnace benefit sintering? Achieve Perfect Dental Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations