In essence, a precise temperature control system ensures that the individual ceramic particles in a restoration fuse together uniformly and completely. By eliminating temperature fluctuations and accurately following a pre-set heating program, the furnace guarantees the final porcelain achieves its maximum intended strength, proper aesthetic qualities, and a precise fit.

The true value of precise temperature control is not just reaching a target temperature, but flawlessly executing a specific temperature-time program, known as the firing curve. This control is what predictably transforms loose ceramic powder into a strong, stable, and aesthetically pleasing final restoration.

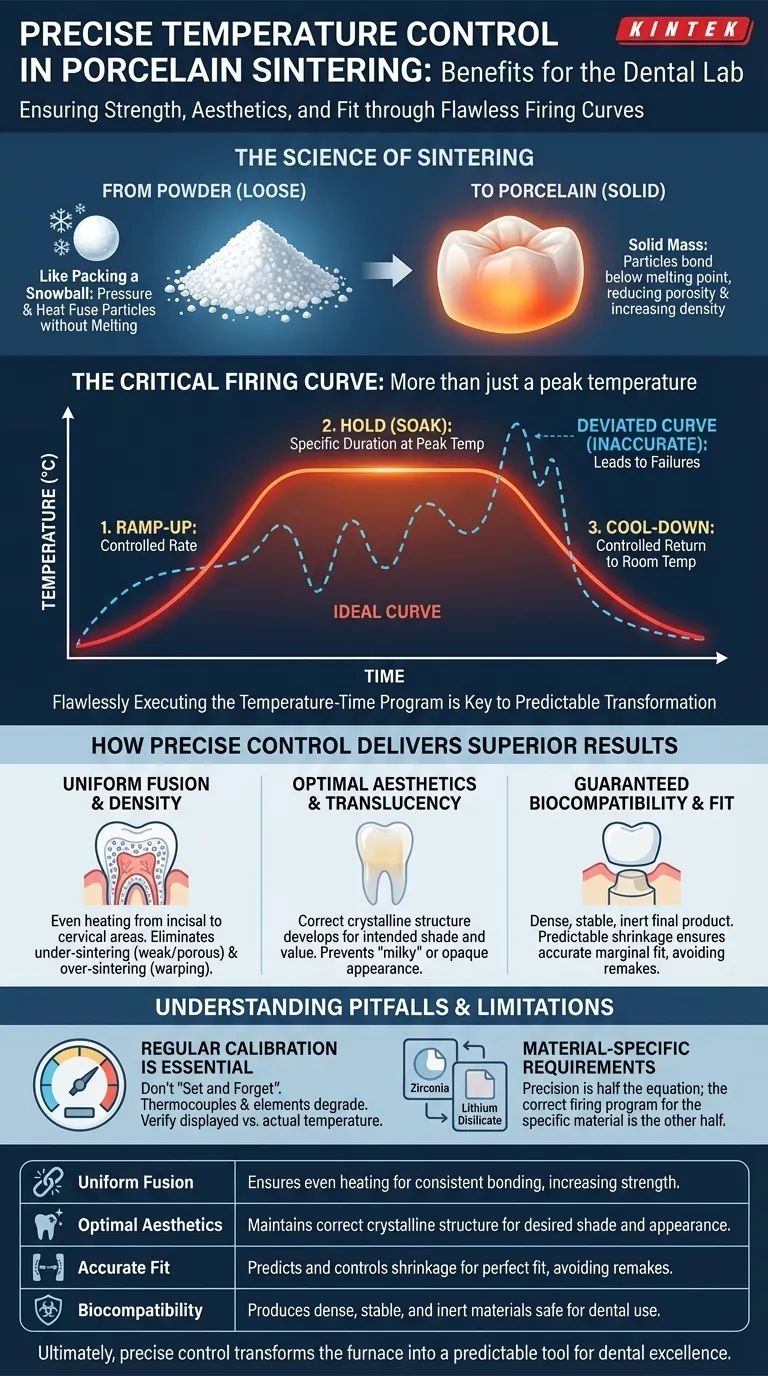

The Science of Sintering: From Powder to Porcelain

To appreciate the importance of control, we must first understand the process it governs. Sintering is a delicate, transformative process that relies on thermal energy.

What is Sintering?

Sintering is a heat treatment that fuses ceramic particles together to form a solid mass. Crucially, this happens at a temperature below the material's melting point.

Think of it like packing a snowball. You apply pressure to fuse individual snowflakes into a solid ball without melting them into water. In a furnace, heat and time provide the energy to bond the particles, reducing porosity and increasing density.

The Critical Role of the Firing Curve

Sintering is not about a single temperature. It's a journey defined by the firing curve, which has distinct phases:

- Ramp-up: The rate at which the temperature increases.

- Hold (or Soak): The specific duration spent at the peak sintering temperature.

- Cool-down: The controlled rate at which the restoration returns to room temperature.

Each ceramic material has a unique, manufacturer-specified firing curve that must be followed exactly to achieve the desired properties.

How Precise Control Delivers Superior Results

Deviating from the ideal firing curve, even by a few degrees, can have significant consequences. A high-precision system mitigates these risks.

Ensures Uniform Fusion and Density

Minimal temperature fluctuations ensure that the entire restoration—from the thin incisal edge to the thicker cervical area—is heated evenly. This uniform heating is critical for consistent fusion of ceramic particles.

Without it, some areas may be under-sintered (leaving them weak and porous) while others might be over-sintered (causing warping or translucency issues).

Achieves Optimal Aesthetics and Translucency

The final shade, value, and translucency of a ceramic restoration are direct results of the crystalline structure formed during sintering.

Precise temperature control ensures this structure develops exactly as intended. Inaccurate temperatures can lead to a "milky" or opaque appearance in materials that should be translucent, requiring a complete remake.

Guarantees Biocompatibility and Fit

Proper sintering results in a dense, stable, and inert final product, which is the foundation of biocompatibility.

Furthermore, all ceramics shrink during sintering. This shrinkage is predictable and accounted for in the design phase, but only if the firing curve is executed perfectly. Poor temperature control leads to unpredictable shrinkage, resulting in restorations that do not fit.

Understanding the Pitfalls and Limitations

Even the most advanced furnace is not a "magic box." Achieving precision requires understanding the potential points of failure.

The Myth of "Set and Forget"

A furnace's precision depends on accurate feedback. The thermocouple (the temperature sensor) and the heating elements degrade over time.

Regular calibration is not optional; it is essential. You must verify that when the furnace displays 900°C, it is actually at 900°C.

The Impact of Inaccurate Calibration

An uncalibrated furnace that is running just 20°C too low will consistently produce under-sintered, weak restorations, even if you follow the correct program. This leads to inexplicable failures and costly remakes.

Material-Specific Requirements

The precision of the furnace is only half the equation. The other half is using the correct firing program for the specific ceramic material.

Using a zirconia program for a lithium disilicate restoration, for example, will lead to a catastrophic failure, regardless of how precise the furnace is.

Applying This to Your Work

Your choice and use of a porcelain furnace should be guided by your specific clinical and business goals.

- If your primary focus is consistency and minimizing remakes: Prioritize a furnace known for its exceptional temperature stability and validated, repeatable firing cycles.

- If your primary focus is working with advanced materials: Ensure the furnace's control system is highly programmable and precise enough for complex materials like multi-layered zirconia that demand intricate firing curves.

- If your primary focus is operational efficiency: Invest in a furnace with reliable components and self-calibration features to reduce downtime and ensure accuracy over the long term.

Ultimately, precise temperature control transforms the porcelain furnace from a simple oven into a predictable manufacturing tool for dental excellence.

Summary Table:

| Benefit | Description |

|---|---|

| Uniform Fusion | Ensures even heating for consistent particle bonding, reducing porosity and increasing strength. |

| Optimal Aesthetics | Maintains correct crystalline structure for desired shade, translucency, and appearance. |

| Accurate Fit | Predicts and controls shrinkage for restorations that fit perfectly, avoiding remakes. |

| Biocompatibility | Produces dense, stable, and inert materials safe for dental use. |

Ready to elevate your dental lab's precision and efficiency?

At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems are engineered with exceptional R&D and in-house manufacturing to deliver precise temperature control, ensuring flawless sintering for materials like porcelain and zirconia. With our strong deep customization capability, we can design furnaces that meet your unique experimental and production needs, minimizing remakes and maximizing output quality.

Contact us today to discuss how our solutions can transform your workflow and deliver superior dental restorations consistently!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab