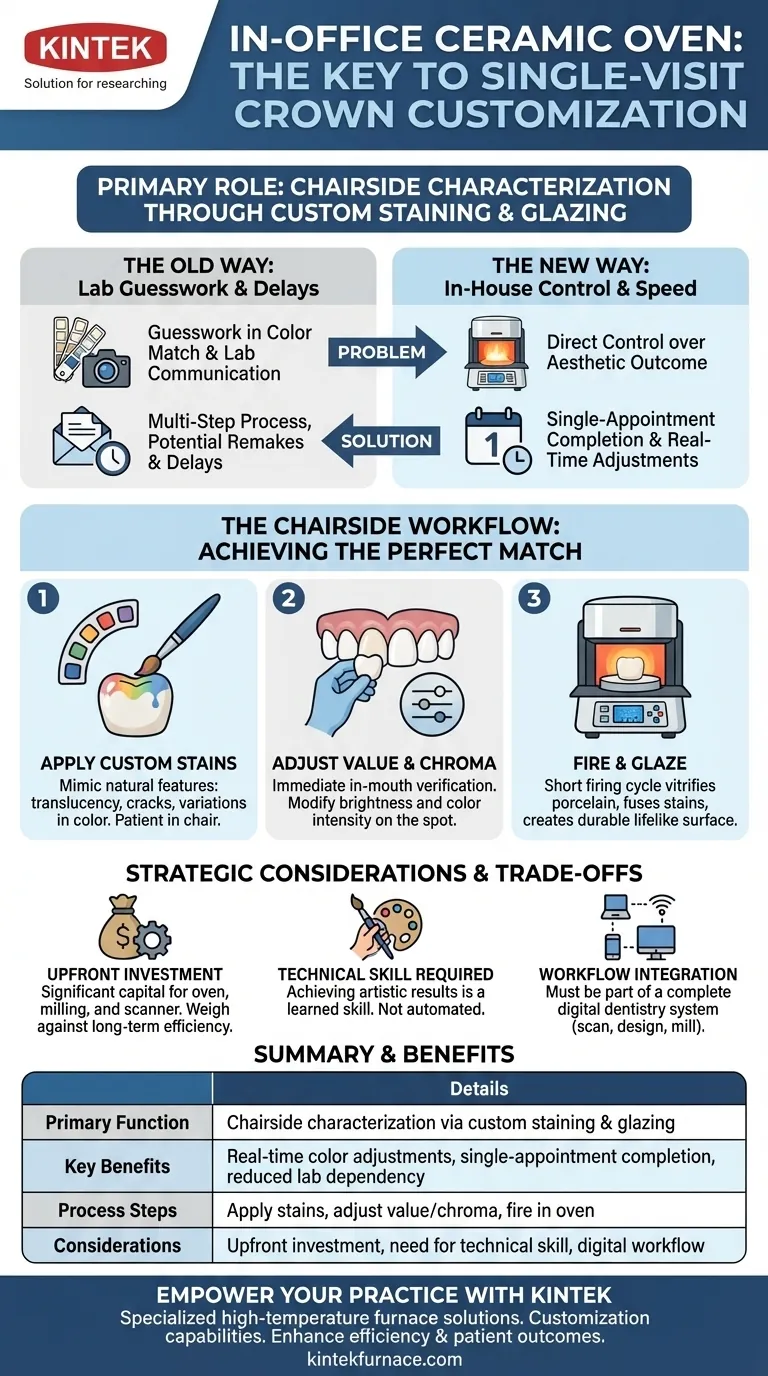

An in-office ceramic oven’s primary role in customization is enabling chairside characterization through custom staining and glazing. This process allows a clinician to take a milled, monochromatic crown and apply specific colors and a final glaze, then fire it in the oven to achieve a perfect match with the patient's adjacent teeth—all within a single appointment.

The true value of an in-office ceramic oven isn't just heating porcelain; it's about transforming the restorative process. It shifts control from an external lab to the clinician's hands, allowing for real-time aesthetic adjustments in a single patient visit.

The Problem: The Limits of Traditional Crown Matching

Before the integration of in-office ovens, achieving a perfect aesthetic match for a dental crown was often a multi-step process fraught with uncertainty and delays.

The Guesswork of Lab Communication

Clinicians traditionally rely on shade guides and detailed photographs to communicate a patient's tooth characteristics to an off-site dental laboratory.

This process is inherently subjective. Describing the subtle translucency, chroma, and value of a tooth is difficult, leading to potential misinterpretations by the lab technician.

The Delay of Remakes

If a crown returns from the lab and doesn't match perfectly, the only option is to send it back. This results in a second or even third patient appointment, creating scheduling challenges and diminishing the patient experience.

How an In-Office Oven Solves This

By bringing the final step of ceramic finishing in-house, the oven empowers clinicians with direct control over the final aesthetic outcome.

Applying Custom Stains

With the patient in the chair, the dentist can apply minute amounts of colored stain to the crown. This allows them to mimic natural features like incisal translucency, subtle cracks, or variations in color that make a tooth look real.

Adjusting Value and Chroma in Real Time

The most significant advantage is the ability to make immediate adjustments. The clinician can hold the stained crown next to the patient's natural teeth and see instantly if the value (brightness) is correct. If it's not, they can modify it on the spot.

The Firing and Glazing Cycle

Once the custom stains are applied, a final glaze layer is added. The crown is then placed in the ceramic oven for a short firing cycle. This process vitrifies the porcelain, permanently fusing the stains and creating a smooth, durable, and lifelike surface.

Understanding the Trade-offs

While powerful, incorporating an in-office oven is a strategic decision that involves more than just the equipment itself.

The Upfront Investment

Chairside milling and firing systems represent a significant capital investment. The cost of the oven, milling unit, and scanner must be weighed against the long-term gains in efficiency and patient satisfaction.

The Need for Technical Skill

Achieving artistic results with stains and glazes is a learned skill. It requires training, practice, and a keen eye for color theory. It is not an automated process; it relies on the clinician's artistic ability.

Workflow Integration

This technology is most effective as part of a complete digital dentistry workflow. It requires seamless integration between intraoral scanning, design software, and the milling unit for the process to be truly efficient.

Making the Right Choice for Your Practice

Integrating an in-office oven is about gaining final control over the restorative process.

- If your primary focus is the ultimate patient experience: This technology delivers the "wow factor" of single-visit crowns that blend seamlessly.

- If your primary focus is operational efficiency: Eliminating lab remakes and follow-up appointments streamlines your schedule and increases procedural profitability.

- If your primary focus is clinical control: An in-office oven is the final piece of the puzzle, giving you direct authority over the aesthetic success of every case.

Ultimately, this technology empowers you to deliver a final restoration that meets your own exacting standards without compromise.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Chairside characterization via custom staining and glazing |

| Key Benefits | Real-time color adjustments, single-appointment completion, reduced lab dependency |

| Process Steps | Apply stains, adjust value/chroma, fire in oven for vitrification |

| Considerations | Upfront investment, need for technical skill, integration with digital workflow |

Ready to take control of your crown customization process? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories and practices. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we can precisely meet your unique experimental and clinical requirements. Enhance your efficiency and patient outcomes—contact us today to discuss how our solutions can benefit your practice!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns