At its core, a rotary furnace is a specialized piece of equipment for the uniform heat treatment of granular, aggregate, or powdery materials. Its defining feature—a rotating cylindrical chamber—ensures that every particle is processed identically, making it essential for applications in powder metallurgy, chemical reactions, catalyst production, and the manufacturing of advanced battery materials.

The fundamental advantage of a rotary furnace is not just heating, but uniform heating through continuous motion. Unlike a static furnace where materials can have hot or cold spots, the rotation guarantees consistent thermal exposure, mixing, and ultimately, a higher quality and more predictable end product.

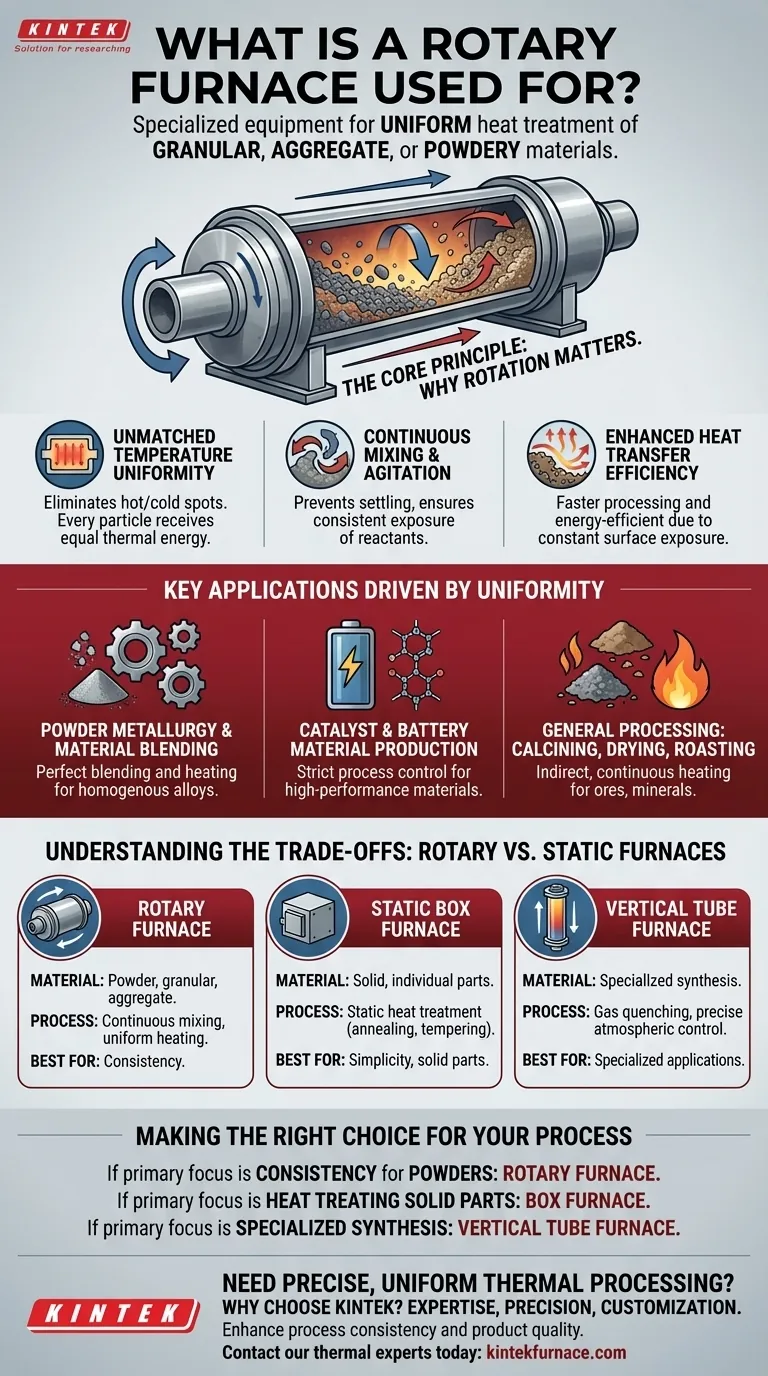

The Core Principle: Why Rotation Matters

The value of a rotary furnace is derived directly from its rotating action. This simple mechanical function delivers three critical process advantages that static furnaces cannot match.

Unmatched Temperature Uniformity

The continuous tumbling of the material inside the chamber eliminates hot and cold spots. This ensures that every granule or particle receives the same amount of thermal energy, which is critical for sensitive processes.

This level of uniformity is essential for applications like catalyst roasting, where uneven heating can result in an inconsistent or ineffective final product.

Continuous Mixing and Agitation

For processes involving chemical reactions or the blending of different powders, the rotating motion provides constant, gentle mixing.

This action prevents settling of denser materials and ensures all reactants are consistently exposed to each other and the furnace's atmosphere, leading to more complete and homogenous reactions.

Enhanced Heat Transfer Efficiency

By constantly exposing new surfaces to the heat source, the tumbling action significantly improves heat transfer. This can lead to faster processing times and more energy-efficient operation compared to heating a static pile of material.

Key Applications Driven by Uniformity

The unique capabilities of a rotary furnace make it the ideal choice for several high-stakes industrial and research applications where consistency is paramount.

Powder Metallurgy and Material Blending

In powder metallurgy, different metal powders must be heated and blended perfectly to create a homogenous alloy. The rotary furnace accomplishes both tasks simultaneously, ensuring a consistent mixture and temperature profile.

Catalyst and Battery Material Production

The performance of catalysts and lithium battery components depends heavily on their precise chemical and physical structure, which is formed during heat treatment. A rotary furnace provides the strict process control needed to produce these high-performance materials reliably.

General Processing: Calcining, Drying, and Roasting

A rotary furnace is also used for more general processes like calcining, roasting, or drying any loose or aggregate material. This includes ores, minerals, and other raw materials that require indirect, continuous heating.

Understanding the Trade-offs: Rotary vs. Static Furnaces

Choosing a furnace is not about finding the "best" one, but the right one for a specific material and process. The main alternative to a rotary furnace is a static box furnace.

When to Choose a Rotary Furnace

A rotary furnace is the superior choice when your material is a powder, granular, or an aggregate. It is non-negotiable if your process requires continuous mixing or if absolute temperature uniformity across the entire batch of material is critical to the outcome.

When a Box Furnace Is a Better Fit

A box furnace is designed for the heat treatment of solid, individual parts or materials that must remain static. It excels at processes like annealing, tempering, or quenching small steel components, or sintering ceramic parts where movement would be detrimental.

The Niche of the Vertical Tube Furnace

A vertical tube furnace serves even more specialized applications. It is often used for processes like gas quenching tests, specific chemical syntheses, or purifications where a vertical orientation and precise atmospheric control are the most important factors.

Making the Right Choice for Your Process

Your material and your end goal dictate the correct technology. Use these guidelines to make a clear decision.

- If your primary focus is process consistency for powders or granules: A rotary furnace is the definitive choice for ensuring uniform heating and mixing.

- If your primary focus is heat treating solid, individual parts: A box furnace provides a simpler, more effective solution for static batch processing.

- If your primary focus is specialized synthesis or gas-phase reactions: A vertical tube furnace is likely designed for your specific application needs.

Ultimately, selecting the right furnace comes down to matching the equipment's core function—dynamic rotation or simple stasis—to the physical nature of your material and your processing goals.

Summary Table:

| Feature | Advantage | Key Application |

|---|---|---|

| Rotating Chamber | Uniform Temperature & Mixing | Powder Metallurgy |

| Continuous Tumbling | Enhanced Heat Transfer | Catalyst Production |

| Gentle Agitation | Prevents Material Settling | Battery Material Manufacturing |

Need Precise, Uniform Thermal Processing for Your Materials?

Your research and production quality depend on consistent, reliable heat treatment. KINTEK's advanced rotary furnaces are engineered to deliver unmatched temperature uniformity and mixing for your granular or powdery materials.

Why Choose KINTEK?

- Expertise in Thermal Solutions: We leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions.

- Precision Engineering: Our rotary furnaces are designed for critical applications in powder metallurgy, chemical synthesis, and advanced material production.

- Deep Customization: We go beyond standard products. Our strong customization capability allows us to tailor a furnace to your unique experimental or production requirements.

Ready to enhance your process consistency and product quality?

Contact our thermal experts today to discuss how a KINTEK rotary furnace can be the solution for you.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing