In essence, a rotary furnace is a cylindrical industrial furnace that rotates along its horizontal axis during operation. It is specifically designed for the continuous heat treatment of materials, particularly those in granular or powder form. The rotation constantly tumbles the material, ensuring every particle is uniformly exposed to heat and the process atmosphere.

The true advantage of a rotary furnace lies not just in its ability to heat materials, but in its capacity to mix them simultaneously. This makes it the ideal solution for processes where temperature uniformity and material homogeneity are critical for the final product's quality.

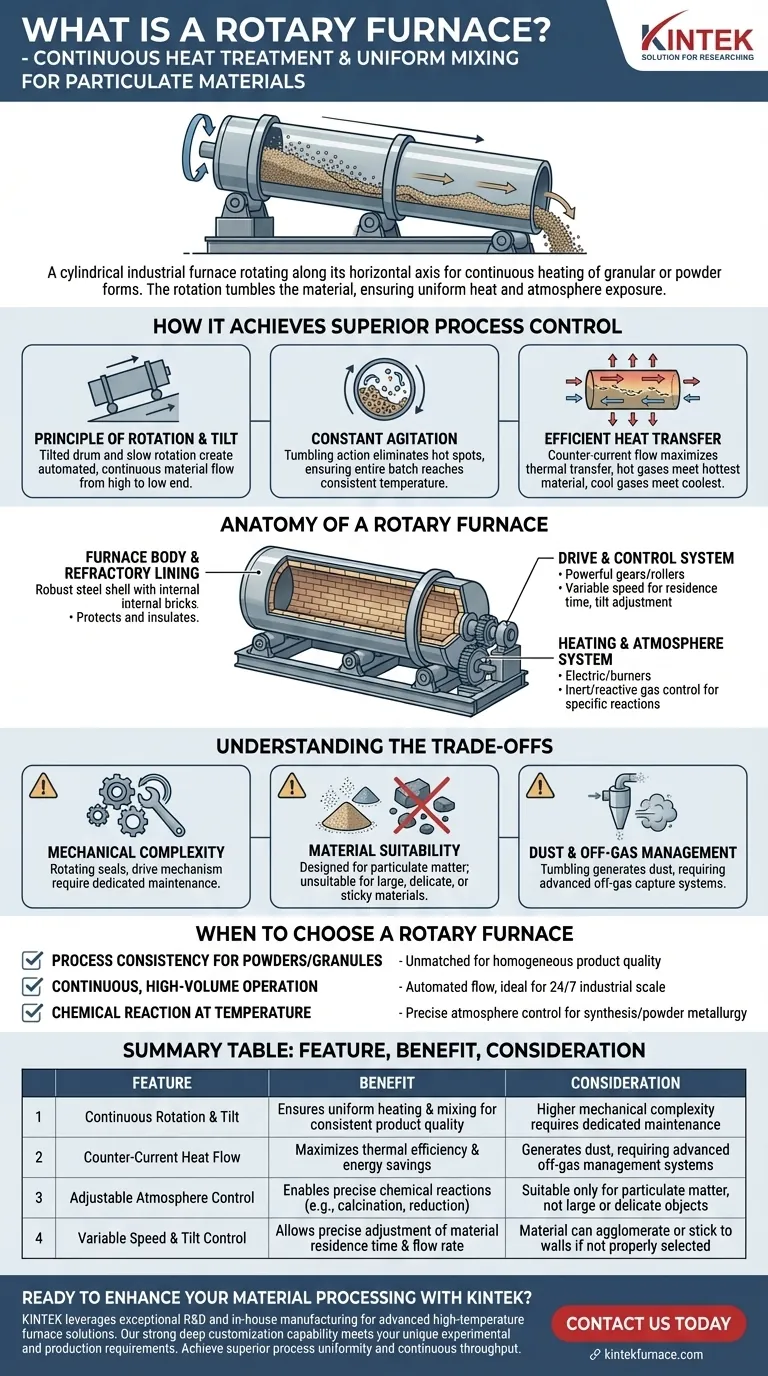

How a Rotary Furnace Achieves Superior Process Control

Unlike a static furnace where material sits idle, a rotary furnace uses dynamic movement to achieve its results. This operational principle is central to its effectiveness.

The Principle of Rotation and Tilt

The furnace is a long tube or drum, mounted at a slight angle. This incline, combined with the slow rotation, causes material fed into the higher end to gradually travel toward the lower end. This design facilitates a continuous, automated flow of material through the heating chamber.

Constant Agitation for Uniform Heating

The core benefit of the furnace is the tumbling action. As the drum turns, the material inside is constantly lifted and cascaded. This movement eliminates hot spots and ensures that the entire batch reaches a consistent temperature, which is difficult to achieve with static piles of material.

Efficient Heat Transfer

Heat is typically supplied by electric elements or by burning gas, oil, or pulverized solids. In many designs, the hot gases flow in the opposite direction of the material (counter-current flow). This method is highly efficient, as the coldest material is met by the coolest gases, and the hottest material is met by the hottest gases, maximizing thermal transfer along the entire length of the furnace.

Anatomy of a Rotary Furnace

Several key components work together to enable this unique processing environment. Understanding them is key to appreciating the furnace's capabilities.

The Furnace Body and Lining

The outer shell is a robust barrel constructed from welded steel plate, sometimes reaching lengths of over 200 meters for large industrial applications. Inside, it is lined with refractory materials like high-temperature bricks or castable cement. This lining serves two purposes: insulating the steel shell from extreme heat and protecting it from chemical corrosion or abrasion from the process material.

The Drive and Control System

A powerful drive gear or set of rollers rotates the entire furnace body. Modern systems feature variable-speed drives, allowing operators to precisely control the rotation speed. This adjusts the material's residence time in the furnace—a critical process parameter. The angle of tilt can also often be adjusted.

The Heating and Atmosphere System

Heating can be provided by external electric elements or internal burners. Beyond just temperature, advanced rotary furnaces allow for precise atmosphere control. Inert gases like nitrogen or reactive gases can be introduced to prevent oxidation or facilitate specific chemical reactions, such as calcination or material reduction.

Understanding the Trade-offs

While powerful, a rotary furnace is a specialized tool. Its advantages come with specific considerations that make it unsuitable for certain applications.

Mechanical Complexity

The rotating seals, drive mechanism, and support rollers introduce a higher level of mechanical complexity compared to a simple box furnace. These moving parts require a dedicated maintenance schedule to ensure reliability and prevent downtime.

Material Suitability

These furnaces are designed for particulate matter. They are not suitable for large, single objects, delicate components that could be damaged by tumbling, or materials that would agglomerate or stick to the furnace walls when heated and rotated.

Dust and Off-Gas Management

The tumbling action can generate significant dust, especially with fine powders. This necessitates a sophisticated system for handling the furnace's off-gas, often including cyclones or baghouses to capture particulate matter before it is released into the environment.

When to Choose a Rotary Furnace

Your decision should be based entirely on your material and process goals.

- If your primary focus is process consistency for powders or granules: The rotary furnace's ability to mix and heat uniformly is unmatched for achieving homogenous product quality.

- If you are running a continuous, high-volume operation: The automated material flow created by the tilt and rotation makes it ideal for industrial-scale, 24/7 production.

- If you need to perform a chemical reaction at temperature: The combination of atmosphere control, constant mixing, and uniform heating provides the perfect environment for powder metallurgy and chemical synthesis.

Ultimately, selecting a rotary furnace is a strategic decision to prioritize process uniformity and continuous throughput for particulate materials.

Summary Table:

| Feature | Benefit | Consideration |

|---|---|---|

| Continuous Rotation & Tilt | Ensures uniform heating and mixing for consistent product quality | Higher mechanical complexity requires dedicated maintenance |

| Counter-Current Heat Flow | Maximizes thermal efficiency and energy savings | Generates dust, requiring advanced off-gas management systems |

| Adjustable Atmosphere Control | Enables precise chemical reactions (e.g., calcination, reduction) | Suitable only for particulate matter, not large or delicate objects |

| Variable Speed & Tilt Control | Allows precise adjustment of material residence time and flow rate | Material can agglomerate or stick to walls if not properly selected |

Ready to enhance your material processing with a custom rotary furnace solution?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Whether you need a standard model or a fully customized system for your specific powders or granules, we can help you achieve superior process uniformity and continuous throughput.

Contact us today to discuss how a KINTEK rotary furnace can optimize your operations!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits