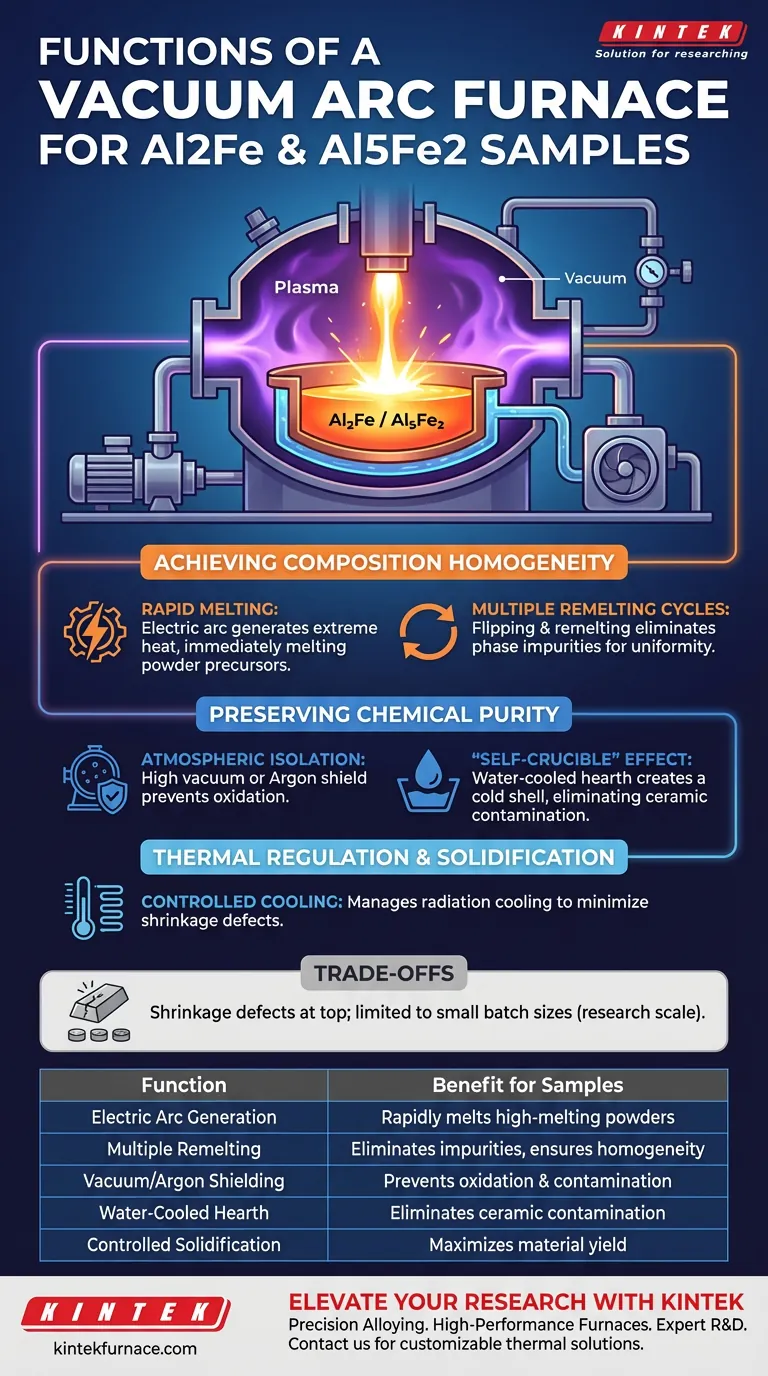

The primary function of a vacuum arc furnace in the preparation of Al2Fe and Al5Fe2 samples is to generate intense, localized heat to rapidly melt metal powders within a strictly controlled environment. It serves as a precision alloying tool designed to eliminate atmospheric contamination while driving the mixture toward chemical homogeneity.

The vacuum arc furnace secures sample quality by combining high-temperature arc melting with a high-vacuum or argon-shielded atmosphere to prevent oxidation. Crucially, it utilizes multiple remelting cycles to eradicate localized chemical deviations, ensuring the final Al2Fe and Al5Fe2 alloys possess a uniform composition free of phase impurities.

Achieving Compositional Homogeneity

Rapid Melting of Precursors

The furnace utilizes an electric arc to generate high instantaneous temperatures. This extreme heat is capable of rapidly melting high-melting-point metal powders, initiating the reaction between aluminum and iron components immediately.

Elimination of Phase Impurities

A single melt is rarely sufficient for complex intermetallics like Al2Fe and Al5Fe2. The furnace facilitates multiple melting cycles, allowing operators to flip and remelt the sample repeatedly. This process ensures full alloying at the microscopic level, preventing the formation of unwanted phase impurities caused by incomplete mixing.

Preserving Chemical Purity

Atmospheric Isolation

The furnace operates under a high vacuum or a protective argon atmosphere. This function is critical for preventing the molten aluminum and iron from reacting with oxygen or nitrogen in the air, which would otherwise compromise the chemical composition accuracy of the alloy.

The "Self-Crucible" Effect

Unlike induction furnaces that may use ceramic containers, vacuum arc furnaces typically employ a water-cooled copper crucible. The efficient cooling creates a solid "cold shell" of the alloy itself against the crucible wall. This eliminates the risk of ceramic contamination, ensuring the internal oxide inclusions and overall purity of the iron alloy samples are maintained at a high level.

Thermal Regulation and Solidification

Controlled Heat Dissipation

A dedicated cooling system regulates the furnace temperature to prevent equipment overheating. This system often uses water-cooled jackets or heat exchangers to manage the intense thermal load generated by the arc.

Managing Solidification Rates

Once the melting is complete, the furnace controls the radiation cooling of the ingot in the vacuum environment. This stage determines how the liquid core shrinks and solidifies. Proper management of this phase is required to minimize shrinkage defects at the top of the ingot, maximizing the material yield.

Understanding the Trade-offs

Shrinkage and Yield Issues

While the water-cooled hearth prevents contamination, it causes the sample to cool rapidly from the bottom up. This can lead to shrinkage defects at the top of the ingot as the liquid core solidifies last.

Sample Size Limitations

Vacuum arc melting is typically a batch process suited for smaller samples or buttons. It is excellent for research and characterization of specific phases like Al5Fe2 but is generally not suitable for large-scale continuous casting compared to other industrial methods.

Making the Right Choice for Your Goal

To maximize the effectiveness of the vacuum arc furnace for your specific alloy samples:

- If your primary focus is Compositional Uniformity: Perform at least 3-4 remelting cycles, flipping the sample between each, to ensure the Al2Fe or Al5Fe2 phases are homogenous throughout the ingot.

- If your primary focus is High Purity: Verify that the vacuum system is fully evacuated before introducing argon, and rely on the water-cooled copper hearth to prevent any trace contamination from crucible materials.

Success in synthesizing these alloys relies on balancing the intensity of the arc with the patience required for multiple remelting iterations.

Summary Table:

| Function | Benefit for Al2Fe/Al5Fe2 Samples |

|---|---|

| Electric Arc Generation | Rapidly melts high-melting-point powders for immediate reaction. |

| Multiple Remelting Cycles | Eliminates phase impurities and ensures chemical homogeneity. |

| Vacuum/Argon Shielding | Prevents oxidation and atmospheric contamination. |

| Water-Cooled Hearth | Creates a 'self-crucible' effect to eliminate ceramic contamination. |

| Controlled Solidification | Manages radiation cooling to maximize material yield. |

Elevate Your Materials Research with KINTEK

Precision alloying of complex intermetallics like Al2Fe and Al5Fe2 requires equipment that offers both power and purity. Backed by expert R&D and manufacturing, KINTEK provides high-performance Vacuum Arc Furnaces, Muffle, Tube, Rotary, and CVD systems designed to meet the rigorous demands of modern laboratories.

Our customizable high-temperature furnaces ensure your samples achieve maximum homogeneity and chemical purity. Contact us today to discover how KINTEK’s advanced thermal solutions can transform your lab's efficiency and research outcomes.

Visual Guide

References

- Yibo Liu, Lifeng Zhang. Orientation Relationship of Intergrowth Al2Fe and Al5Fe2 Intermetallics Determined by Single-Crystal X-ray Diffraction. DOI: 10.3390/met14030337

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a Vacuum Magnetic-controlled Arc Furnace in AFA alloys? Ensure Purity & Uniformity

- Why is multiple flipping and remelting necessary for Ti10Mo8Nb alloy? Ensure Homogeneity in High-Performance Alloys

- What are the limitations of induction heating? High Costs, Material Limits, and EMI Explained

- How does a Vacuum Induction Furnace function in Silicon-Manganese deoxidation simulation? Achieve High-Purity Results

- How does an induction furnace work? Achieve Clean, Fast, and Controlled Metal Melting

- What are the benefits of reduced furnace lining burn loss in IGBT induction melting furnaces? Lower Total Casting Costs

- Why are graphite crucibles and induction furnaces equipped with protective gas systems used for Zn-SiC composites?

- What are the key components of an induction heating system? Master Efficient, Contactless Heating Solutions