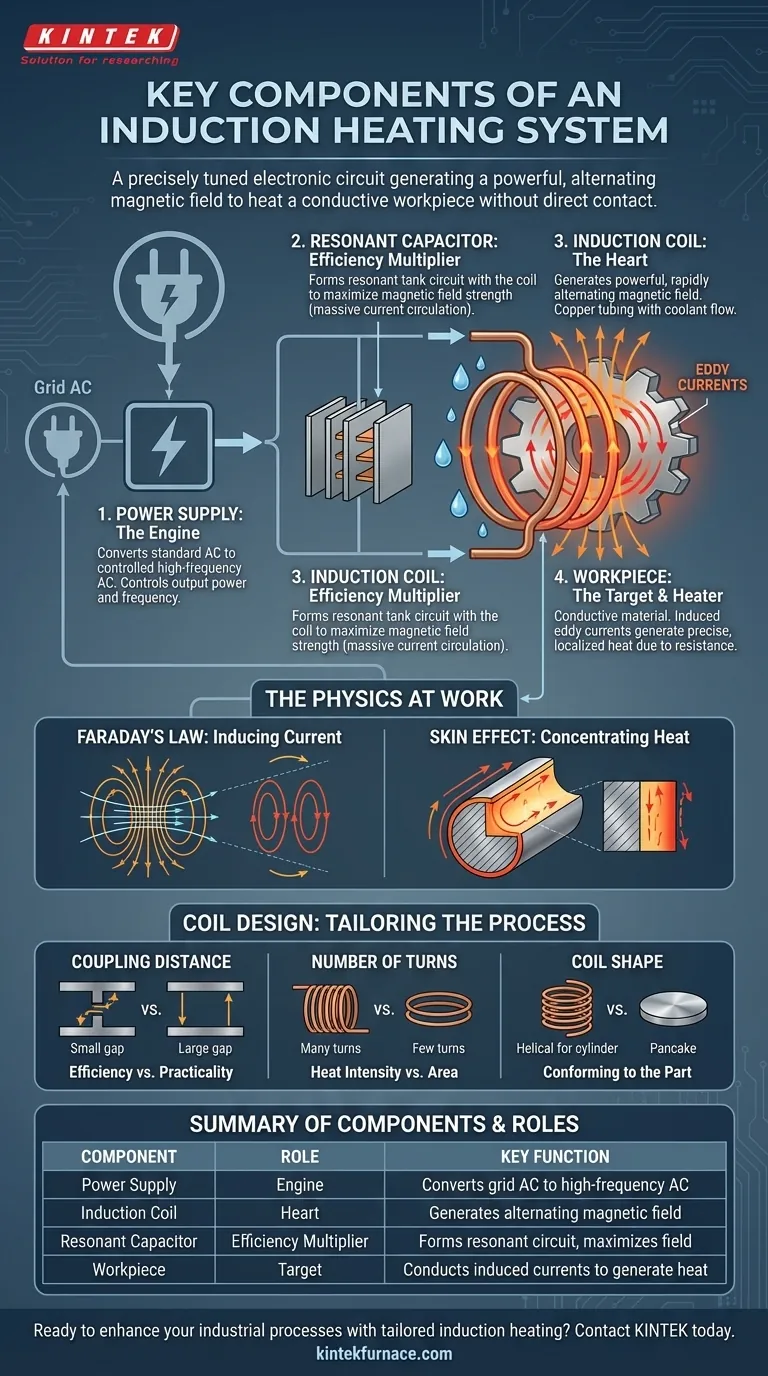

At its core, an induction heating system is comprised of three primary electronic components. These are a high-frequency AC power supply, an induction coil (or workhead), and a resonant capacitor. Together, they form a tuned circuit that generates a powerful, alternating magnetic field used to heat a conductive workpiece without direct contact.

An induction heating system is more than a list of parts; it's a precisely tuned circuit designed to generate a powerful, high-frequency magnetic field. The key is understanding that each component works in concert to induce electrical currents directly within the target material, turning the material itself into the source of heat.

The Core Components and Their Roles

Each part of the system has a distinct and critical function. The efficiency and effectiveness of the heating process depend on these components working in perfect harmony.

The Power Supply: The Engine of the System

The power supply is the starting point. It takes standard AC power from the grid and converts it into a high-frequency alternating current.

This is not a simple transformer. It's a sophisticated electronic device that allows operators to control the output power and frequency, which are critical variables in the heating process.

The Induction Coil (Workhead): The Heart of the Process

The induction coil is arguably the most recognizable component. It is typically made from copper tubing, through which a coolant (usually water) flows to prevent the coil itself from overheating.

When the high-frequency current from the power supply flows through this coil, it generates a powerful and rapidly alternating magnetic field in the space within and around it. The design of this coil is paramount to the success of the application.

The Resonant Capacitor: The Efficiency Multiplier

The capacitor works in parallel with the induction coil to create a resonant tank circuit. Think of this like pushing a child on a swing; if you push at just the right time (the resonant frequency), a small effort results in a large swing.

Similarly, the resonant circuit allows for a massive amount of current to circulate between the capacitor and the coil. This maximizes the strength of the magnetic field for a given output from the power supply, making the entire system highly efficient.

The Workpiece: The Target and the Heater

While not a component of the system itself, the workpiece is a critical part of the electrical process. When the conductive workpiece is placed within the coil's magnetic field, the field induces electrical currents within it.

These induced currents, known as eddy currents, flow against the material's electrical resistance, generating precise and localized heat. The workpiece effectively becomes its own heating element.

The Physics That Make It Work

Two fundamental principles of physics govern how these components function together to produce heat.

Faraday's Law: Inducing the Current

Faraday's Law of Induction states that a changing magnetic field will induce an electrical current in a conductor placed within it. The induction coil creates this rapidly changing field, and the workpiece is the conductor where the eddy currents are generated.

The Skin Effect: Concentrating the Heat

The Skin Effect is a phenomenon where high-frequency AC currents tend to flow on the outer surface of a conductor. In induction heating, this is a major advantage.

By using high frequencies, the heat-generating eddy currents are concentrated in a thin layer on the workpiece's surface. This allows for extremely rapid and controlled surface heating, ideal for applications like case hardening gears or other metal parts.

Understanding the Trade-offs: Coil Design

The design of the induction coil is the most important factor in tailoring the process to a specific part. It involves critical trade-offs that impact efficiency and the final result.

Coupling Distance: Efficiency vs. Practicality

The "coupling distance" is the gap between the coil and the workpiece. A smaller gap results in a stronger magnetic field and more efficient energy transfer.

However, the coil must not touch the workpiece, and there needs to be enough room to place and remove the part. The goal is always to make this distance as small as is practically possible.

Number of Turns: Heat Intensity vs. Area

The number of turns in the coil affects the concentration of the magnetic field. More turns in a given area will generally produce a more intense heating effect over a smaller band.

Fewer, more widely spaced turns will heat a larger surface area but with less intensity. The choice depends entirely on the desired heat pattern for the part.

Coil Shape: Conforming to the Part

For heating to be uniform, the magnetic field must be applied evenly to the target surface. This means the coil must be shaped to conform to the geometry of the workpiece. A simple cylindrical part uses a helical coil, while a flat surface might require a flat "pancake" style coil.

Making the Right Choice for Your Goal

Your application's specific goal will determine which aspects of the system you need to focus on.

- If your primary focus is process efficiency: Concentrate on the resonant circuit and achieving tight coil coupling to maximize energy transfer into the part.

- If your primary focus is a precise heat pattern: The design of the induction coil—its shape, size, and number of turns—is your most critical variable.

- If your primary focus is rapid surface hardening: You must leverage high frequencies to take full advantage of the Skin Effect, which concentrates heat on the workpiece's outer layer.

Understanding these components and their interplay empowers you to move beyond simply using an induction system to truly mastering the process for your specific application.

Summary Table:

| Component | Role | Key Function |

|---|---|---|

| Power Supply | Engine | Converts grid AC to high-frequency AC for controlled heating |

| Induction Coil | Heart | Generates alternating magnetic field to induce eddy currents |

| Resonant Capacitor | Efficiency Multiplier | Forms resonant circuit to maximize magnetic field strength |

| Workpiece | Target | Conducts induced currents to generate localized heat |

Ready to enhance your industrial processes with tailored induction heating? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including induction systems. Our product line—featuring Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how we can optimize your heating applications for maximum efficiency and precision!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does an induction furnace improve energy efficiency in gold melting? Achieve Faster, Purer Melts

- How do induction furnaces enhance safety during the smelting process? Achieve Cleaner, Safer Metal Melting

- What types of metals and alloys are typically melted in induction-heated vacuum furnaces? Essential for High-Performance Materials

- What industries commonly use vacuum casting and for what applications? Discover Versatile Solutions for Prototyping and High-Performance Parts

- Why is precise temperature control important in induction furnaces? Achieve Metallurgical Excellence

- What are the primary functions of a Vacuum Induction Melting (VIM) furnace? Optimize Ni30 Superalloy Purity

- What factors should be considered when selecting an induction melting furnace for a business? Maximize Efficiency and ROI