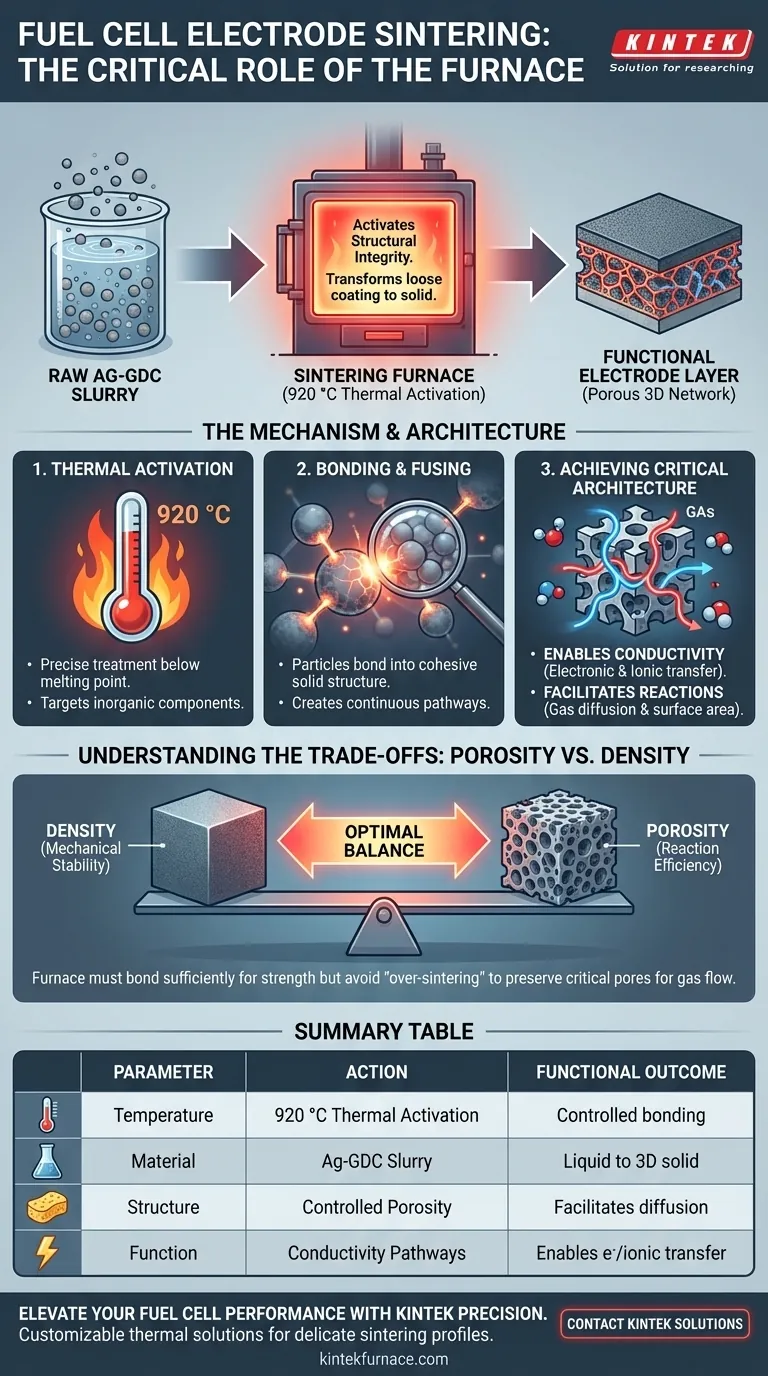

The sintering furnace performs the critical task of activating the electrode's structural integrity. It subjects the coated layers to a specific thermal treatment of 920 °C. This intense heat causes the inorganic components within the Ag-GDC slurry to bond, transforming a loose coating into a functional, three-dimensional solid.

The furnace transforms the electrode from a raw slurry into a complex, porous architecture. This thermal processing is essential for creating the physical pathways required for both electrical conduction and chemical reactions.

The Mechanism of Structural Formation

Thermal Activation at 920 °C

The furnace operates at a specific set point of 920 °C during this phase of production.

This temperature is carefully calibrated to be below the melting point of the materials but high enough to activate sintering.

Bonding Inorganic Components

The heat targets the inorganic components within the Ag-GDC (Silver-Gadolinium Doped Ceria) slurry.

Through this thermal energy, the particles begin to bond and fuse together. This creates a cohesive solid structure from the original liquid or paste-like coating.

Achieving the Critical Architecture

Creating a Three-Dimensional Network

The primary output of this sintering process is a porous, three-dimensional network.

Unlike a fully dense block of material, this network maintains open internal spaces. This specific architecture is not a defect; it is a functional requirement for the fuel cell's operation.

Enabling Conductivity

The solid parts of this network provide the necessary "roads" for energy transfer.

Specifically, the sintered structure establishes continuous pathways that allow for both electronic and ionic conduction throughout the electrode layer.

Facilitating Chemical Reactions

The open, porous voids within the structure are equally important.

They offer the necessary physical space for the diffusion of ammonia decomposition products. Furthermore, these voids provide the surface area required for the fuel cell's electrochemical reactions to occur efficiently.

Understanding the Trade-offs

Porosity vs. Density

While general sintering often aims to maximize density to increase strength, fuel cell electrodes require a delicate balance.

The furnace must bond the particles sufficiently to ensure mechanical stability and conductivity.

However, it must not "over-sinter" the material to the point where the pores close up. If the structure becomes too dense, it will block the diffusion pathways for gases like ammonia, rendering the cell ineffective.

Making the Right Choice for Your Goal

To optimize the electrode layer, you must view the sintering profile as a variable that controls the ratio of conduction to diffusion.

- If your primary focus is mechanical stability: Ensure the thermal treatment is sufficient to fully bond the inorganic Ag-GDC components into a robust network.

- If your primary focus is reaction efficiency: Verify that the 920 °C treatment preserves enough porous space to accommodate ammonia decomposition and gas flow.

The sintering furnace is not just a heater; it is the architect of the electrode’s internal landscape.

Summary Table:

| Process Parameter | Action/Mechanism | Functional Outcome |

|---|---|---|

| Temperature | 920 °C Thermal Activation | Controlled bonding of inorganic components |

| Material | Ag-GDC Slurry | Transformation from liquid coating to 3D solid |

| Structure | Controlled Porosity | Facilitates gas diffusion and ammonia decomposition |

| Function | Conductivity Pathways | Enables electronic and ionic conduction across the layer |

Elevate Your Fuel Cell Performance with KINTEK Precision

Unlock the full potential of your electrode architecture with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems specifically engineered to handle delicate sintering profiles like the 920 °C Ag-GDC process.

Whether you are scaling production or refining lab-scale research, our high-temp furnaces provide the uniform heating and precise control necessary to balance mechanical stability with critical porosity.

Ready to optimize your fuel cell production? Contact us today to discuss your unique needs.

Visual Guide

References

- Zeyu Lin, Bo Liang. Ammonia-Fueled Tubular Solid Oxide Fuel Cell Using a Plasma-Enhanced Cracking Reactor. DOI: 10.1021/acs.energyfuels.5c03027

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum carburizing improve surface quality? Achieve Clean, High-Strength Parts

- How does a vacuum sintering furnace facilitate the final densification of 3D-printed fused silica glass? Expert Guide

- What is the role of a vacuum packaging furnace in the semiconductor industry? Ensure Hermetic Sealing for Reliable Devices

- How do multiple-chamber vacuum furnaces improve energy efficiency? Cut Costs with Continuous Heating

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- Why must the drying process for MXene-coated electrodes be conducted in a vacuum drying oven? Key Stability Factors

- What are the key thermal properties of graphite for vacuum furnaces? Unlock High-Temperature Stability and Efficiency

- What are some common types of vacuum furnaces? Explore Their Uses and Benefits