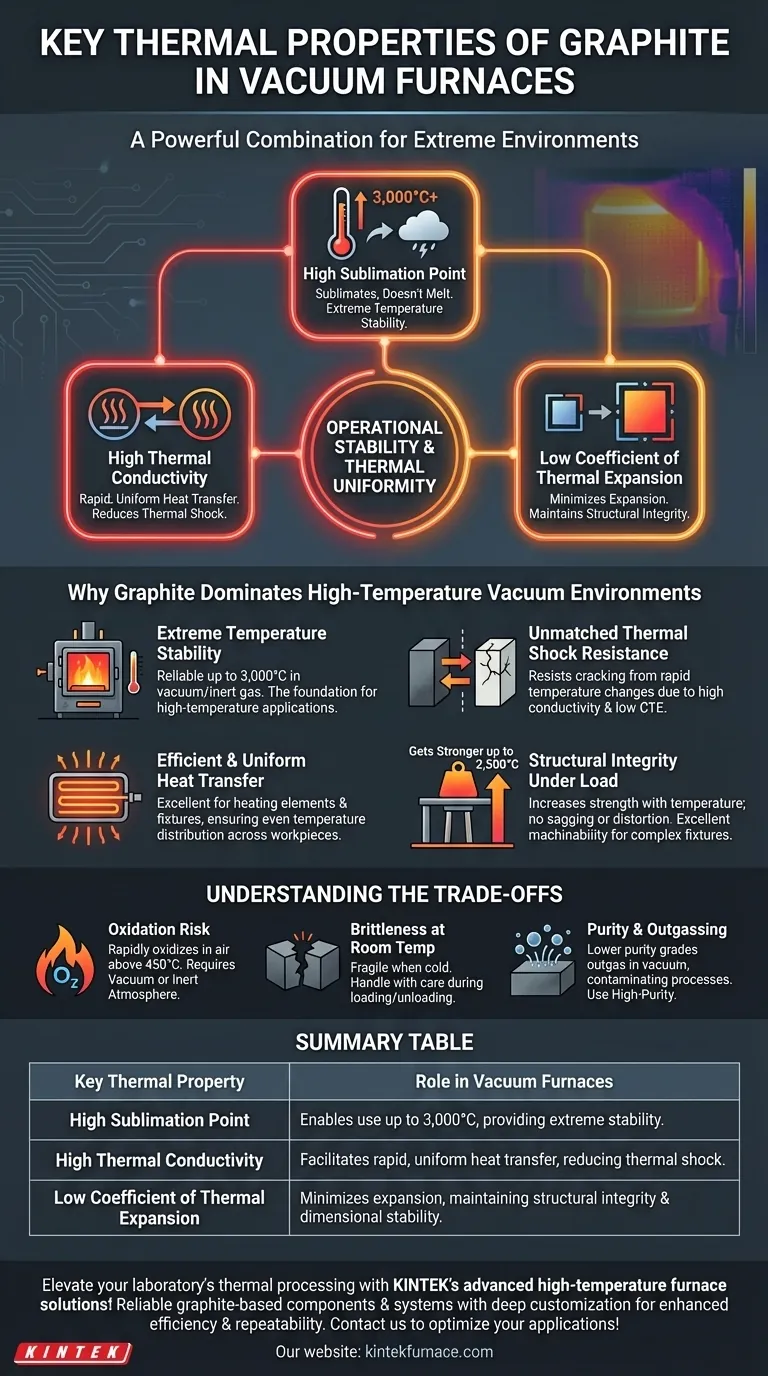

At its core, graphite's suitability for vacuum furnaces stems from a powerful combination of three thermal properties: an extremely high sublimation point, high thermal conductivity, and a very low coefficient of thermal expansion. This unique trio allows it to not only survive extreme temperatures but to provide the stable, predictable environment essential for high-precision thermal processing.

Graphite is the material of choice for vacuum furnace components because it doesn't just resist heat. Its properties work in concert to deliver operational stability, thermal uniformity, and structural integrity under conditions where most other materials would fail catastrophically.

Why Graphite Dominates High-Temperature Vacuum Environments

To understand graphite's role, we must look beyond its simple heat resistance and examine how its distinct properties solve critical challenges in vacuum furnace operation.

Extreme Temperature Stability

Graphite does not melt at atmospheric pressure. Instead, it sublimates (turns from a solid directly to a gas) at an exceptionally high temperature, around 3,600°C.

In the inert gas or vacuum environment of a furnace, it can be reliably used for applications requiring temperatures up to 3,000°C. This forms the foundation for all its high-temperature applications.

Unmatched Thermal Shock Resistance

Thermal shock is the stress a material endures during rapid temperature changes, often causing cracks. Graphite's resistance to this is one of its most valuable traits.

This resistance is a direct result of two properties working together:

- High Thermal Conductivity: Heat moves through the material quickly, preventing the formation of "hot spots" and reducing internal stress.

- Low Coefficient of Thermal Expansion (CTE): When heated, graphite expands very little. This minimizes the physical strain placed on the component during rapid heating or cooling cycles.

Think of it like pouring hot water into a thick, cold glass versus a thin metal cup. The glass (low conductivity, high expansion) cracks, while the metal cup (high conductivity) handles the shock. Graphite behaves like an ideal version of that metal cup.

Efficient and Uniform Heat Transfer

High thermal conductivity makes graphite an excellent material for heating elements and workpiece fixtures.

As a heating element, it efficiently converts electrical energy into heat and radiates that heat uniformly throughout the furnace's hot zone.

As a fixture or tooling, it quickly absorbs heat and transfers it evenly to the product being treated. This ensures there are no significant temperature differences across the part, which is critical for processes like brazing and annealing.

Structural Integrity Under Load

Many materials weaken, soften, or warp at high temperatures. Graphite is unique in that it actually gets stronger as it gets hotter, up to about 2,500°C.

Combined with its low CTE, this means graphite fixtures, posts, and support grids will not sag, bend, or distort under the load of the workpiece. This dimensional stability is essential for process repeatability.

Furthermore, graphite's excellent machinability allows for the creation of complex and precise fixtures that would be difficult or impossible to fabricate from other high-temperature materials like ceramics or refractory metals.

Understanding the Trade-offs

While incredibly capable, graphite is not without its limitations. Acknowledging these is key to using it successfully.

Oxidation in the Presence of Air

Graphite's remarkable high-temperature performance is entirely dependent on a vacuum or inert atmosphere.

If exposed to oxygen at high temperatures (typically above 450°C), it will rapidly oxidize and literally burn away, leading to component failure and potential damage to the furnace.

Brittleness at Room Temperature

While strong when hot, solid graphite can be brittle and fragile at room temperature. Components must be handled with care during furnace loading, unloading, and maintenance to avoid chipping or cracking.

Purity and Outgassing

Graphite is available in various purity grades. Lower-purity grades can contain binders or contaminants that will outgas when heated in a vacuum.

This release of vapor can contaminate the vacuum atmosphere and, more critically, the surface of the product being heat-treated. Using high-purity graphite is essential for sensitive applications like electronics or medical implants.

Making the Right Choice for Your Application

Selecting the right graphite component means matching its properties to your primary process goal.

- If your primary focus is process stability and repeatability: Choose high-purity, dimensionally stable graphite for your fixtures and tooling to ensure parts are held precisely cycle after cycle.

- If your primary focus is heating efficiency and uniformity: Utilize graphite heating elements for their excellent electrical and thermal conductivity, which provides rapid, even, and controllable radiant heat.

- If your primary focus is furnace efficiency and insulation: Employ graphite felt as hot zone insulation for its low thermal conductivity (in felt form) and exceptional resistance to heat, creating a durable and efficient thermal barrier.

Ultimately, graphite's unique synthesis of thermal and structural properties makes it an enabling material, foundational to modern high-performance thermal processing.

Summary Table:

| Key Thermal Property | Role in Vacuum Furnaces |

|---|---|

| High Sublimation Point | Enables use up to 3,000°C without melting, providing extreme temperature stability. |

| High Thermal Conductivity | Facilitates rapid, uniform heat transfer, reducing thermal shock and hot spots. |

| Low Coefficient of Thermal Expansion | Minimizes expansion under heat, maintaining structural integrity and dimensional stability. |

Elevate your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable graphite-based components and systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced efficiency, stability, and repeatability. Contact us today to discuss how our tailored solutions can optimize your high-temperature applications!

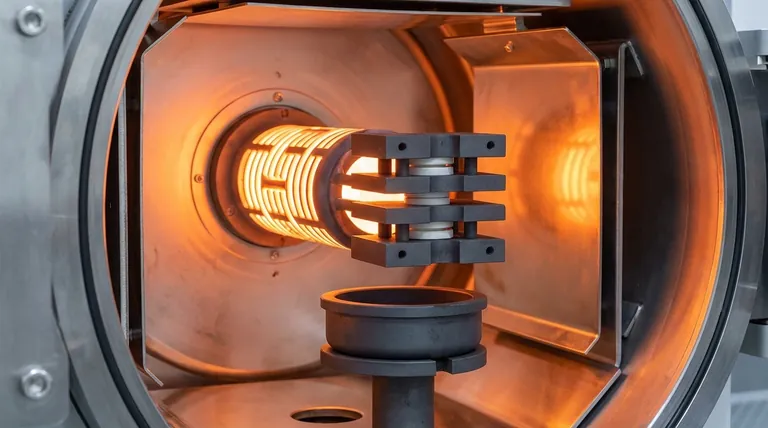

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity