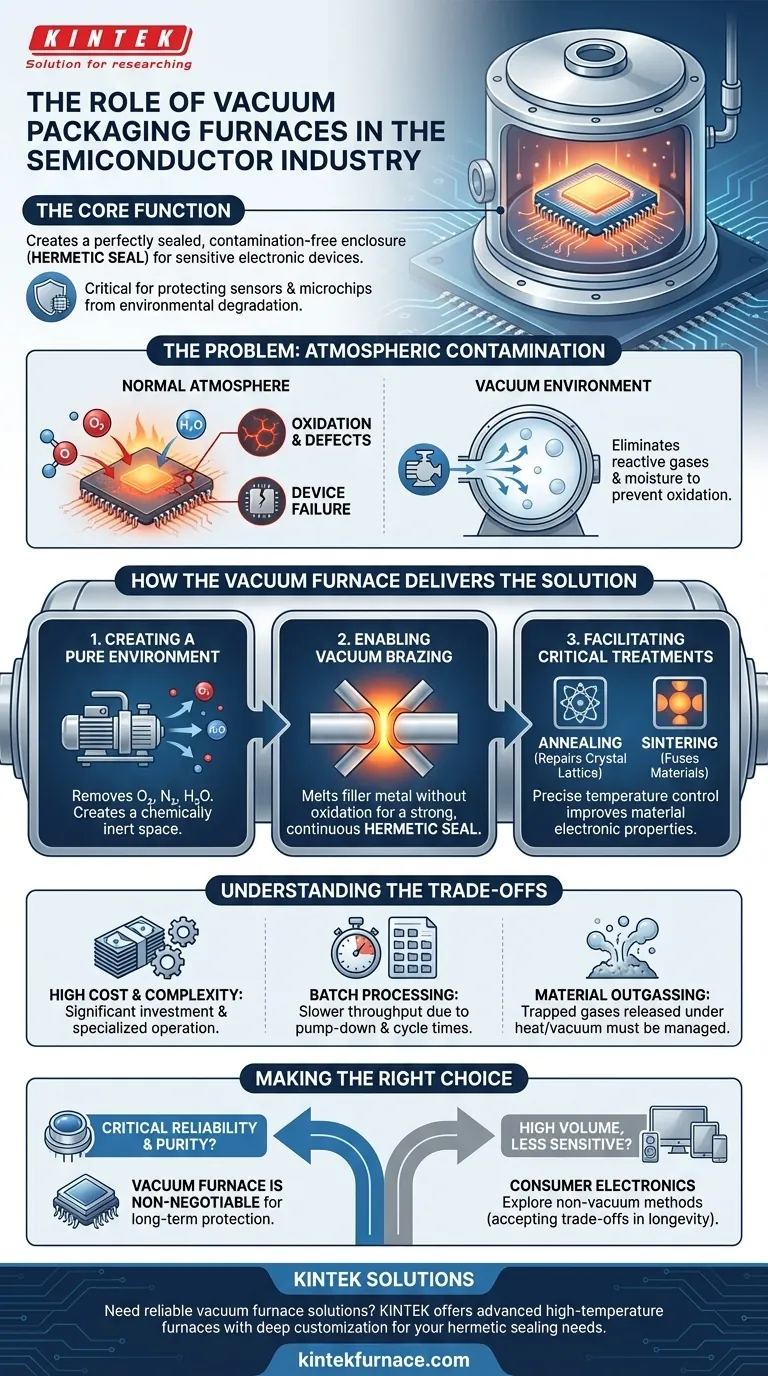

At its core, a vacuum packaging furnace is a specialized high-temperature chamber used in semiconductor manufacturing to create a perfectly sealed, contamination-free enclosure around a sensitive electronic device. This process, often involving vacuum brazing, is not merely for "packaging" in the conventional sense; it is a critical step to hermetically seal components like sensors and microchips, protecting them from environmental factors that would otherwise cause them to degrade and fail.

The central purpose of using a vacuum furnace is to eliminate the single biggest threat to high-performance electronics during thermal processing: atmospheric contamination. By removing air and its reactive elements, the furnace creates an ultra-pure environment where materials can be joined and treated without the risk of oxidation or impurities compromising the final device.

The Fundamental Problem: Atmospheric Contamination

Why a Normal Atmosphere is the Enemy

Semiconductor devices are built from materials that are highly reactive, especially at the elevated temperatures required for manufacturing and sealing.

In a normal atmosphere, elements like oxygen and water vapor will instantly react with hot surfaces. This process, known as oxidation, creates unwanted films, alters material properties, and introduces structural defects at a microscopic level.

The Impact on Device Performance

For a high-reliability sensor or integrated circuit, even a minuscule amount of contamination or a microscopic breach in its seal can be catastrophic.

These defects can lead to signal noise, performance drift, reduced operational lifespan, or immediate device failure. The goal of vacuum processing is to prevent these issues before they can ever form.

How a Vacuum Furnace Delivers the Solution

Creating a Chemically Pure Environment

The primary function of the vacuum is to remove the air inside the furnace chamber. This act eliminates the reactive gases—primarily oxygen and nitrogen—and water vapor that would otherwise interfere with delicate processes.

This creates a stable, predictable, and chemically inert environment, which is essential for the high-precision work of semiconductor fabrication and packaging.

Enabling High-Temperature Sealing

The most important application for a packaging furnace is enabling vacuum brazing. Brazing is a process where a filler metal is melted to join two components, such as a microchip and its protective casing.

Performing this under vacuum prevents the filler metal and the components themselves from oxidizing. The result is a clean, strong, and continuous hermetic seal that is impervious to gas or moisture, permanently protecting the device inside.

Facilitating Critical Heat Treatments

Beyond just packaging, vacuum furnaces are indispensable for other thermal processes that ensure the quality of the silicon itself.

Processes like annealing (which repairs crystal lattice damage) and sintering (which fuses materials together) require precise temperature control in a contaminant-free space. A vacuum ensures these treatments improve the material's electronic properties without introducing unwanted chemical reactions.

Understanding the Trade-offs

High Cost and Complexity

Vacuum furnaces are sophisticated and expensive pieces of equipment. They require significant capital investment, specialized knowledge for operation, and rigorous maintenance schedules to maintain the integrity of their vacuum systems.

Throughput and Cycle Time

Creating a high-quality vacuum is not an instantaneous process. Pumping down the chamber, running the thermal cycle, and cooling the components takes time. This makes vacuum furnace processing a batch process, which is inherently slower than continuous, atmospheric-based manufacturing lines.

Material Outgassing

A significant challenge in vacuum processing is outgassing, where gases trapped within the components or furnace walls are released under heat and vacuum. These released gases can become a new source of contamination and must be carefully managed by the furnace's pumping system, adding another layer of complexity to the process.

Making the Right Choice for Your Goal

Ultimately, the decision to use a vacuum furnace is a strategic one, driven by the required level of quality and reliability for the end product.

- If your primary focus is long-term reliability for critical devices: A vacuum packaging furnace is non-negotiable for creating a true hermetic seal that guarantees protection from environmental degradation.

- If your primary focus is maintaining material purity during heat treatment: A vacuum furnace is the only way to reliably perform annealing or sintering without introducing oxidation that compromises electronic performance.

- If your primary focus is high-volume production of less sensitive components: You may explore non-vacuum packaging methods, but you must accept the inherent trade-off in device protection and longevity.

Using a vacuum furnace is not just about enclosure; it is a foundational step in guaranteeing the integrity and performance of high-value semiconductor devices.

Summary Table:

| Aspect | Role in Semiconductor Industry |

|---|---|

| Primary Function | Creates a contamination-free environment for hermetic sealing and thermal processing. |

| Key Processes | Vacuum brazing, annealing, sintering to protect sensitive components. |

| Benefits | Prevents oxidation, ensures device longevity, and maintains material purity. |

| Challenges | High cost, batch processing, and management of outgassing. |

Need reliable vacuum furnace solutions for your semiconductor lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for hermetic sealing and contamination-free processing. Contact us today to enhance your device reliability and performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control