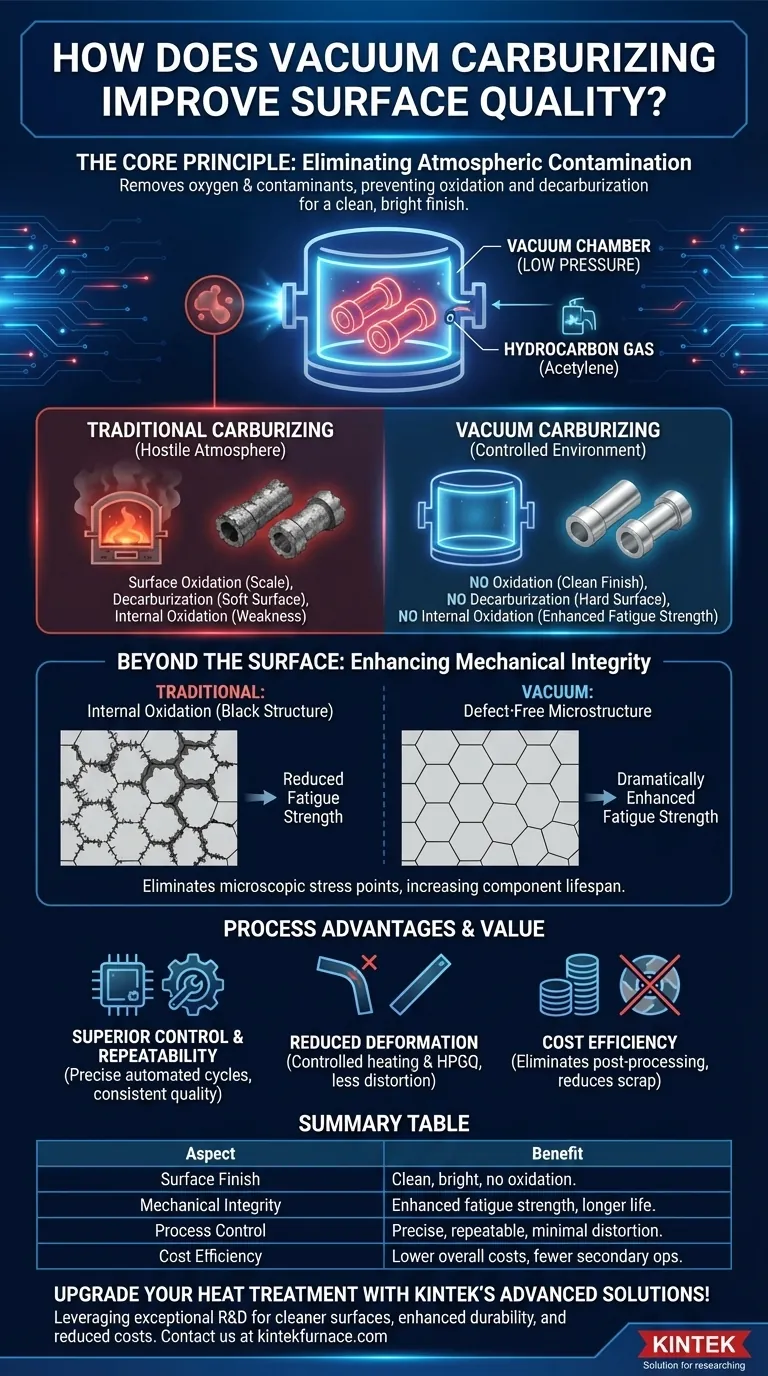

At its core, vacuum carburizing improves surface quality by fundamentally changing the environment in which the heat treatment occurs. By removing oxygen and other atmospheric contaminants, the process eliminates the root cause of common surface defects like oxidation and decarburization, resulting in a clean, bright finish and superior metallurgical integrity.

The critical insight is that traditional carburizing fights against a hostile atmosphere, while vacuum carburizing removes the atmosphere entirely. This prevents not only visible surface scale but also the microscopic, sub-surface defects that compromise the mechanical performance and fatigue life of a component.

The Core Principle: Eliminating Atmospheric Contamination

The primary advantage of vacuum carburizing stems from performing the process in a controlled, low-pressure environment. This prevents unwanted chemical reactions between the heated metal surface and the surrounding atmosphere.

What is Vacuum Carburizing?

Vacuum carburizing, also known as Low-Pressure Carburizing (LPC), is a case-hardening process. Parts are heated to high temperatures—typically between 1600–1950°F (870–1070°C)—inside a vacuum chamber.

A hydrocarbon gas, most commonly acetylene, is then introduced at a very low pressure. The gas decomposes, allowing carbon to diffuse into the steel's surface and form a hard, wear-resistant layer, or "case."

Preventing Surface Oxidation

In traditional heat treatments, the high temperatures cause the metal surface to react with oxygen in the air, forming a dark, rough layer of oxide scale.

Because vacuum carburizing removes the oxygen, this reaction cannot occur. The result is a part that retains its original metallic luster and a bright, smooth surface finish, eliminating the need for subsequent cleaning or polishing.

Averting Decarburization

Decarburization is the loss of carbon from the surface of steel, which can occur in atmospheric furnaces. This leaves the surface softer than intended, reducing wear resistance.

The precisely controlled environment in vacuum carburizing ensures there are no reactive agents to draw carbon out of the steel, preserving the surface's chemical integrity.

Beyond the Surface: Enhancing Mechanical Integrity

The benefits of vacuum carburizing extend deep below the visible surface, directly impacting the component's structural and mechanical properties.

The Elimination of Internal Oxidation

A significant flaw in conventional gas carburizing is intergranular or internal oxidation. Oxygen penetrates along the grain boundaries of the steel, forming oxide networks just below the surface.

This defect, often called a "black structure," acts as a series of microscopic stress points, severely reducing the material's fatigue strength. Vacuum carburizing completely prevents this defect from forming.

The Direct Impact on Fatigue Strength

By eliminating both surface and internal oxidation, vacuum carburizing produces a cleaner, more uniform microstructure.

This defect-free surface layer dramatically enhances the fatigue strength of the component. Parts become more reliable and have a longer service life, which is critical for high-performance applications like gears and bearings.

Understanding the Process Advantages and Trade-offs

While the metallurgical benefits are clear, the process itself offers distinct advantages in control and consistency, though it comes with its own set of considerations.

Superior Control and Repeatability

The entire vacuum carburizing cycle is managed by microprocessors. This allows for precise control and monitoring of temperature, pressure, and gas flow.

This high degree of automation reduces human error and process variables, ensuring that every part in a batch—and every subsequent batch—receives a highly consistent and repeatable treatment.

Reduced Deformation for Complex Parts

The vacuum allows for highly controllable heating speeds. This minimizes the temperature difference between a part's surface and its core, reducing thermal stress and minimizing distortion.

Furthermore, quenching is often performed with high-pressure gas (HPGQ) in the same vacuum chamber. This controlled cooling is less severe than traditional oil quenching, further reducing deformation, especially in complex or thin-walled geometries. This often reduces the need for costly post-treatment grinding.

The Cost and Complexity Consideration

Vacuum furnaces represent a significant capital investment, and cycle times can sometimes be longer than for conventional methods.

However, these upfront costs are often offset by eliminating post-processing steps like shot blasting or grinding, reducing scrap rates from distortion, and the superior performance and lifespan of the final product.

Making the Right Choice for Your Application

Selecting a carburizing method depends on the specific demands of your component.

- If your primary focus is maximum fatigue life and reliability: Vacuum carburizing is the superior choice because its elimination of internal oxidation directly translates to enhanced component longevity.

- If your primary focus is processing complex or thin-walled parts: Vacuum carburizing offers unmatched dimensional stability due to its controlled heating and quenching cycles, minimizing distortion and post-treatment work.

- If your primary focus is a clean, bright finish without secondary operations: The process inherently produces an oxide-free surface, making it ideal for parts where final appearance is critical.

Ultimately, choosing vacuum carburizing is a strategic decision to engineer a higher-quality component from the surface inward.

Summary Table:

| Aspect | Benefit |

|---|---|

| Surface Finish | Eliminates oxidation and decarburization for a clean, bright finish |

| Mechanical Integrity | Prevents internal oxidation, enhancing fatigue strength and component lifespan |

| Process Control | Offers precise, repeatable treatment with minimal distortion for complex parts |

| Cost Efficiency | Reduces need for post-processing like grinding, lowering overall costs |

Upgrade your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering cleaner surfaces, enhanced part durability, and reduced operational costs. Contact us today to discuss how our tailored vacuum carburizing furnaces can optimize your component quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety