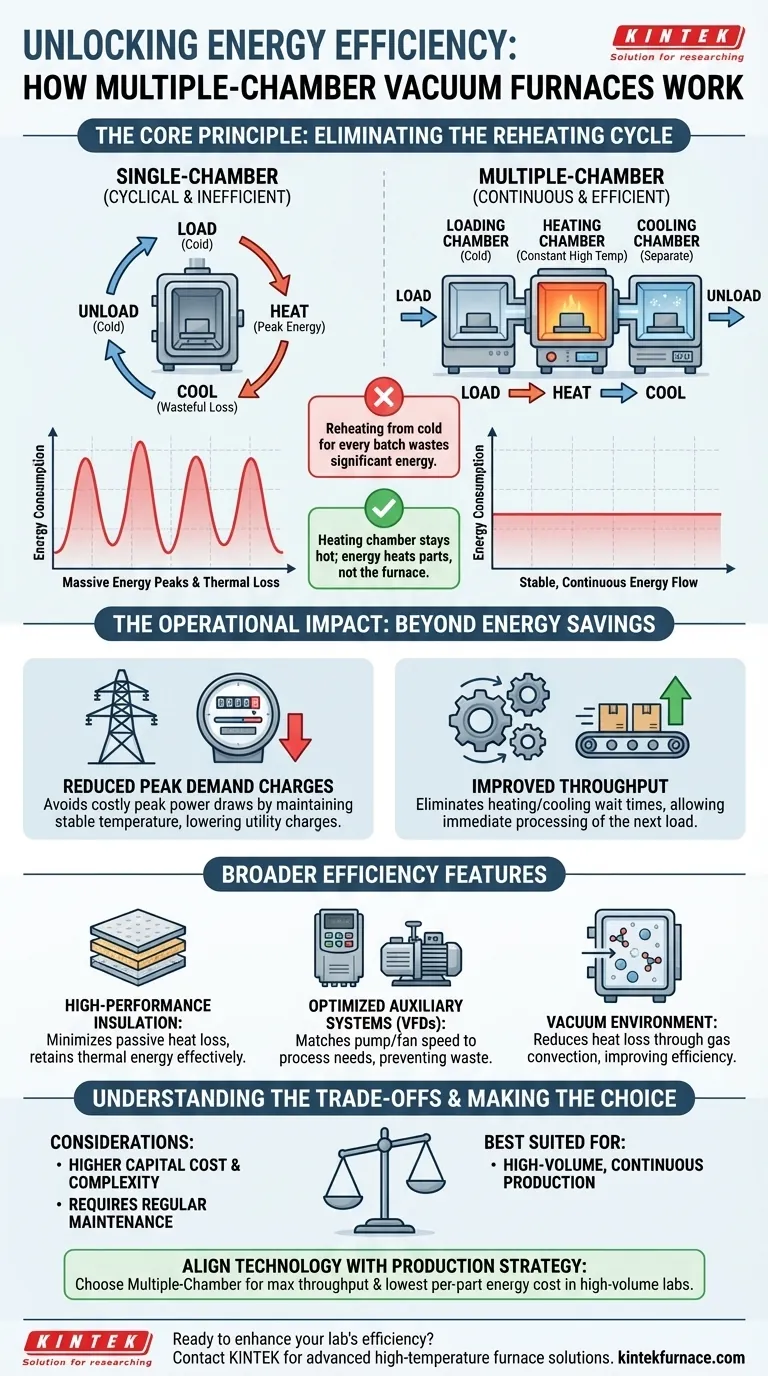

The fundamental energy efficiency of a multiple-chamber vacuum furnace comes from its ability to keep the heating chamber at a constant high temperature. By moving workloads through separate loading, heating, and cooling zones, it eliminates the massive energy waste associated with reheating a single-chamber furnace from a cold state for every single batch.

A multiple-chamber furnace separates the heating process from loading and cooling, transforming energy usage from a costly, cyclical peak-and-valley model into a stable, continuous flow. The energy is spent heating the parts, not reheating the furnace.

The Core Principle: Eliminating the Reheating Cycle

The most significant energy drain in batch heat-treating is not maintaining temperature, but achieving it. Multiple-chamber designs attack this specific point of inefficiency.

How Single-Chamber Furnaces Waste Energy

A conventional single-chamber furnace must complete a full cycle for each load. This involves heating up, holding, cooling down, unloading, and then starting the entire process over again.

Each time the chamber cools, the thermal energy stored in its walls, insulation, and components is lost. Reheating this entire thermal mass for the next batch requires a massive spike in energy consumption.

The Multi-Chamber Workflow

A multiple-chamber system functions more like a continuous production line. It consists of separate, isolated modules for loading, heating, and quenching or cooling.

The key is that the heating chamber remains at operating temperature between loads. Workpieces are moved from a loading chamber into the pre-heated furnace, and then moved out to a separate cooling chamber, all while the heating elements remain stable.

Directing Energy to the Workpiece

Because the hot zone is never allowed to cool down, the available energy is consumed almost exclusively by the workload itself. The furnace is no longer fighting to restore its own temperature, allowing for more precise and efficient heat transfer to the parts being treated.

The Operational Impact of Thermal Stability

This shift from a cyclical to a continuous heating model has benefits that extend beyond simple energy savings.

Reducing Peak Demand Charges

The large power draw required to bring a cold single-chamber furnace up to temperature creates a significant "peak demand" on the electrical grid. Many utility providers levy steep charges based on these peaks, regardless of overall consumption.

A multiple-chamber furnace, by maintaining a stable temperature, draws a much more consistent and lower level of power. This flattens the demand curve, directly reducing or eliminating costly peak demand charges.

Improving Throughput

By eliminating the lengthy reheating and cooling phases from the heating chamber's cycle, the system's overall throughput increases dramatically. As soon as one load moves to the cooling chamber, the next can immediately enter the hot zone.

Broader Efficiency Features

While the multi-chamber design is the primary driver of efficiency, other modern features contribute to lower energy use.

The Role of High-Performance Insulation

Modern furnaces use advanced insulation materials, such as high-quality polycrystalline mullite fiber. This material allows for rapid heating while providing exceptional thermal retention, minimizing passive heat loss and conserving energy. Features like double-layer furnace shells further enhance this effect.

Optimizing Auxiliary Systems

Energy efficiency is a whole-system concern. Features like Variable Frequency Drives (VFDs) on vacuum pumps and cooling fans allow their speed and energy consumption to be precisely matched to the process need, avoiding the waste of running them at full power unnecessarily.

Vacuum vs. Atmosphere Environments

The vacuum environment itself contributes to efficiency by minimizing heat loss through gas convection. In contrast, atmosphere furnaces achieve a similar goal by using a controlled environment of inert gases to prevent oxidation and reduce heat transfer away from the workpiece.

Understanding the Trade-offs

No technology is without its compromises. A multiple-chamber furnace's efficiency comes with specific considerations.

Higher Initial Capital Cost

The complexity of a multi-chamber system, with its additional chambers, doors, vacuum seals, and transfer mechanisms, results in a significantly higher upfront investment compared to a single-chamber furnace.

Maintenance and Complexity

More moving parts and isolated systems mean a more complex maintenance schedule. Each chamber and transfer mechanism is a potential point of failure that must be monitored and maintained to ensure reliable operation.

Best Suited for High-Volume Production

The energy-saving benefits of a continuously hot furnace are only realized in high-volume, semi-continuous production environments. If your workflow involves infrequent batches or long idle periods, the energy required to keep the hot zone at temperature may negate the savings.

Making the Right Choice for Your Goal

To select the appropriate technology, you must match the furnace architecture to your production strategy.

- If your primary focus is maximum throughput and the lowest per-part energy cost: A multiple-chamber furnace is the superior choice for high-volume, repetitive work.

- If your primary focus is flexibility for varied, low-volume, or intermittent jobs: A single-chamber furnace offers a lower capital investment and may be more cost-effective if it will not be in constant use.

- If your primary focus is overall system optimization: Look for modern features like VFDs, advanced insulation, and sophisticated control systems, regardless of whether you choose a single or multiple-chamber design.

Ultimately, aligning the furnace's operational model with your production volume and financial goals is the key to making a sound investment.

Summary Table:

| Feature | Benefit |

|---|---|

| Continuous heating chamber | Eliminates energy waste from reheating, stabilizes power use |

| Separate loading and cooling zones | Increases throughput, reduces cycle times |

| Reduced peak demand | Lowers electricity charges, flattens energy consumption |

| High-performance insulation | Minimizes heat loss, conserves energy |

| Optimized auxiliary systems | Matches energy use to process needs, e.g., via VFDs |

| Vacuum environment | Reduces heat loss through convection, improves efficiency |

Ready to enhance your lab's energy efficiency and throughput? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to learn how our multiple-chamber vacuum furnaces can save energy and boost productivity for your high-volume applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today