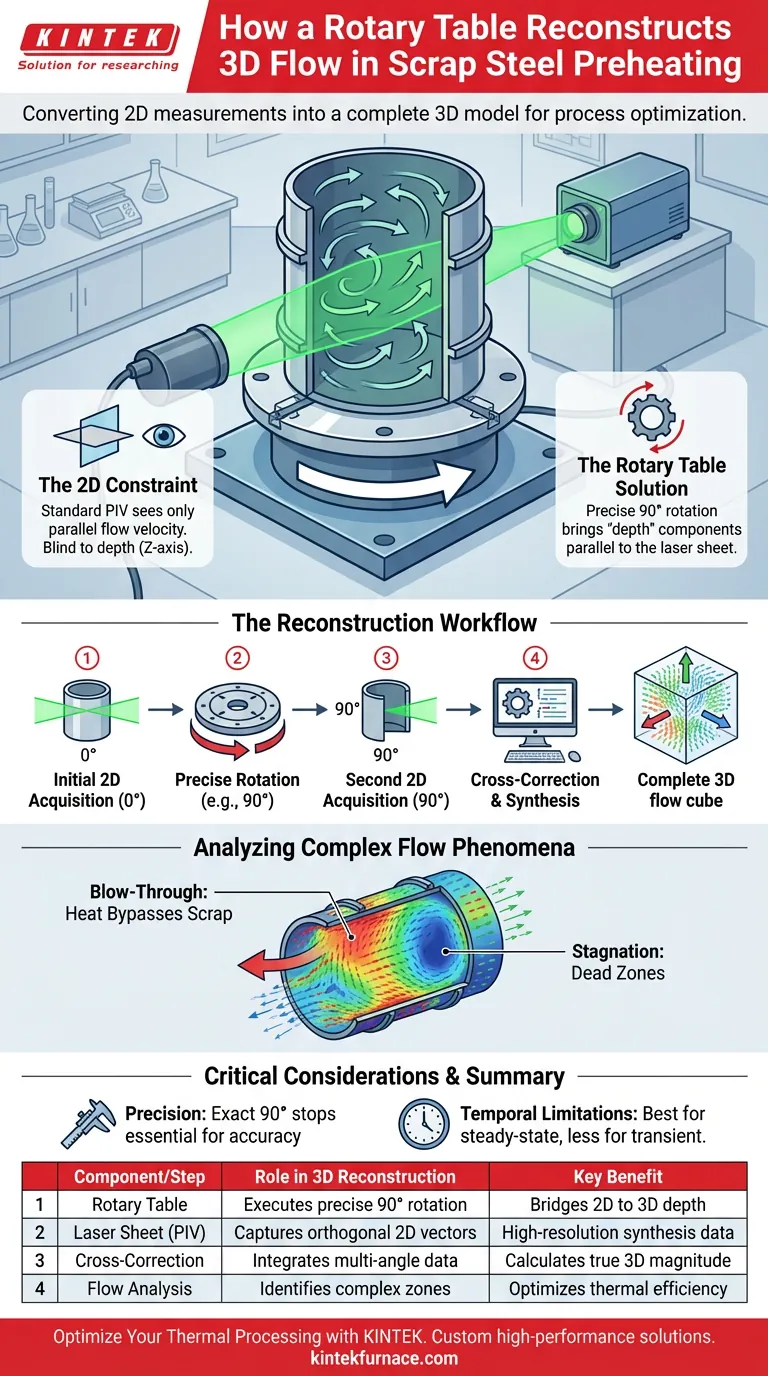

A rotary table functions as a critical mechanical interface that enables the conversion of two-dimensional measurements into a three-dimensional model. By precisely changing the orientation of the experimental scrap steel container relative to the laser observation system, it allows researchers to capture flow velocity data from multiple angles—typically differing by 90 degrees—which is essential for synthesizing a complete 3D flow field.

Standard Particle Image Velocimetry (PIV) systems are inherently limited to measuring flow in a single flat plane. The rotary table overcomes this constraint by rotating the subject, allowing the combination of orthogonal 2D datasets to mathematically reconstruct full 3D velocity vectors.

Overcoming the Two-Dimensional Limit

The Constraint of Laser Observation

In experimental setups involving scrap steel preheating, the flow field is often observed using a laser sheet, such as in a PIV system.

This technology creates a single plane of light. Consequently, it can only measure velocity components that are parallel to that sheet. It is blind to any movement occurring "in or out" of the light plane (the third dimension).

The Role of Controlled Rotation

To capture the missing dimension without installing complex multi-camera volumetric systems, the rotary table physically moves the experiment.

By rotating the container 90 degrees, the flow components that were previously unobservable (perpendicular to the laser sheet) are brought parallel to it. This mechanical shift effectively allows a 2D sensor to see the "depth" of the flow.

The Reconstruction Workflow

Acquiring Orthogonal Data

The process relies on taking distinct measurements at specific intervals.

First, a 2D velocity field is acquired at the initial orientation. The rotary table then executes a precise turn to the secondary angle. A second set of 2D data is acquired from this new perspective.

Cross-Correction and Synthesis

The raw data from these different angles cannot simply be overlaid; it must be mathematically integrated.

Through a process of cross-correction, the datasets are analyzed together. The system correlates the velocity vectors from the first angle with those from the rotated angle to calculate the true magnitude and direction of the flow in 3D space.

Analyzing Complex Flow Phenomena

This 3D reconstruction is not merely academic; it is vital for understanding the efficiency of preheating scrap steel.

The reconstructed vectors allow for the quantitative analysis of specific phenomena, such as blow-through (where heat bypasses the scrap) and stagnation (dead zones where air does not circulate). These complex behaviors cannot be accurately identified with simple 2D imaging.

Critical Considerations for Accuracy

The Necessity of Precision

The effectiveness of this reconstruction method hinges entirely on the accuracy of the rotary table.

If the rotation is not exactly 90 degrees (or the intended angle), the cross-correction algorithms will produce erroneous vector fields. The table must offer high mechanical fidelity to ensure the coordinate systems align perfectly.

Temporal Limitations

This method assumes a relationship between the measurements taken before and after rotation.

Because the rotation takes time, this approach is most effective when analyzing steady-state flows or when using statistical averaging. It is generally less suited for capturing transient, split-second fluctuations compared to expensive simultaneous 3D camera setups.

Ensuring Successful Reconstruction

Making the Right Choice for Your Goal

- If your primary focus is quantitative accuracy: Ensure the rotary table is calibrated to exact 90-degree stops to minimize geometric errors during the cross-correction phase.

- If your primary focus is process optimization: Use the reconstructed 3D data specifically to map "blow-through" channels, as identifying these leakages offers the highest return on preheating efficiency.

Precise mechanical rotation acts as the bridge between standard 2D observation and advanced 3D volumetric understanding.

Summary Table:

| Component/Step | Role in 3D Reconstruction | Key Benefit |

|---|---|---|

| Rotary Table | Executes precise 90-degree container rotation | Bridges the gap between 2D laser planes and 3D depth |

| Laser Sheet (PIV) | Captures 2D velocity vectors at orthogonal angles | Provides high-resolution data for mathematical synthesis |

| Cross-Correction | Integrates datasets from multiple orientations | Correlates vectors to calculate true 3D magnitude |

| Flow Analysis | Identifies blow-through and stagnation zones | Optimizes thermal efficiency in scrap steel containers |

Optimize Your Thermal Processing with KINTEK

Precise flow field reconstruction is critical for maximizing heat transfer in industrial applications. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial heating needs.

Whether you are refining scrap steel preheating processes or developing advanced materials, our high-temperature solutions provide the mechanical fidelity and thermal precision you require. Contact us today to discuss your custom furnace requirements and see how our expertise can drive your innovation.

Visual Guide

References

- Manabu Tange, K. Tsutsumi. Relationship between the Nonuniformity of Packed Structure and Fluid Permeability in a Model Scrap Preheating Vessel. DOI: 10.2355/isijinternational.isijint-2023-458

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What roles does a rotary cement kiln play in cement production? Uncover Its 4 Critical Functions

- What are the main components of a rotary tube sintering furnace? Discover the Key Parts for Uniform Heating

- Why is a vacuum or atmosphere-controlled rotary furnace necessary for SiC conversion? Master PIP Ceramic Pyrolysis

- What are the advantages of a rotary tube furnace for activated carbon? Achieve Dynamic Homogeneity and Pore Control

- What are the heating mechanisms used in a rotary kiln? Optimize Your Industrial Process

- How are rotary kilns used in the cement industry? Master Clinker Production for Efficiency

- How are rotary furnaces utilized in metallurgical applications? Unlock Efficient Metal Processing and Recycling

- How does the design and operation of a carbonization furnace influence biomass fuel production? High-Efficiency Sludge Conversion