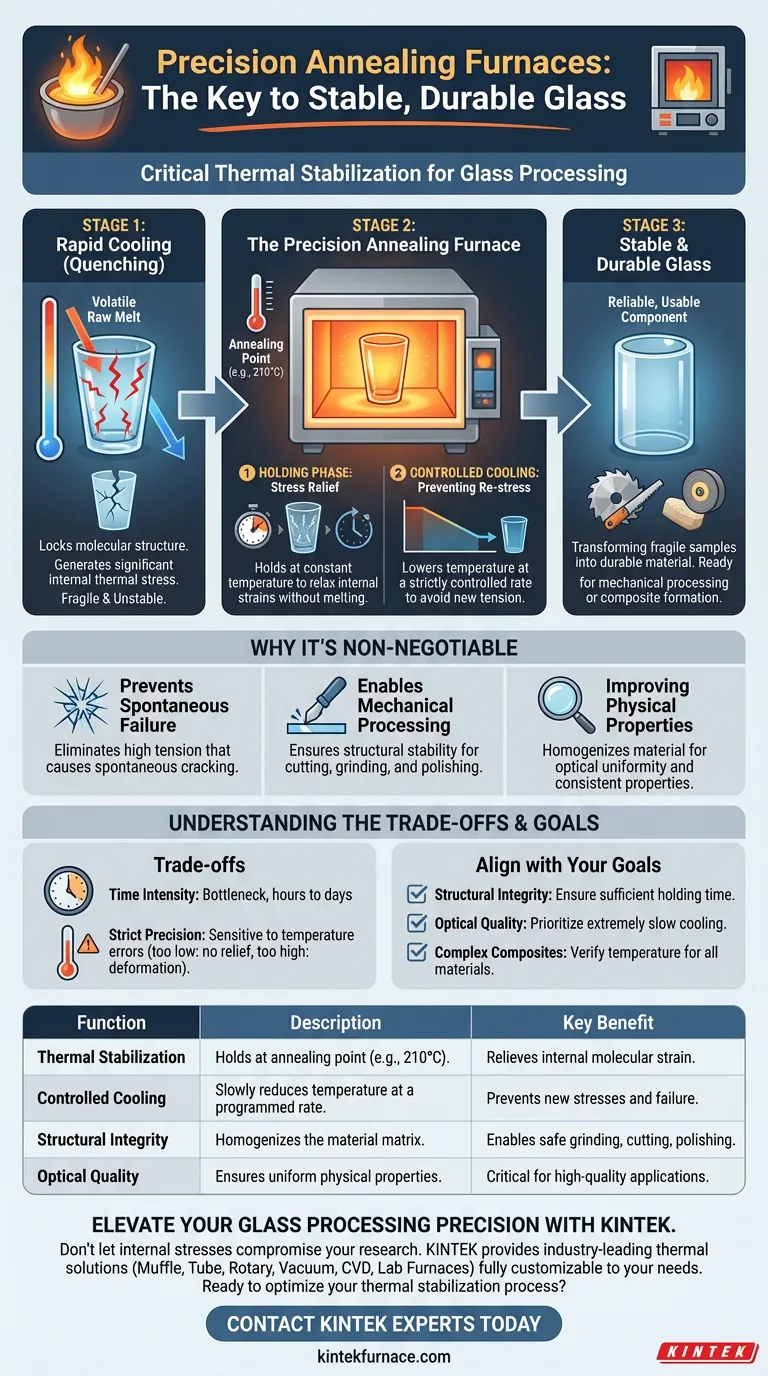

A precision annealing furnace functions as a critical thermal stabilization tool designed to mitigate the destructive effects of rapid cooling on molten glass. Its primary role is to hold the glass at a specific temperature slightly above its transition point—such as 210°C—to effectively release internal thermal stresses before the material is allowed to cool to room temperature.

By subjecting the glass to this controlled thermal treatment, the furnace prevents the material from cracking or shattering due to tension. This process transforms a fragile, unstable sample into a durable material ready for mechanical processing or composite formation.

The Mechanics of Stress Relief

Counteracting Rapid Cooling

When molten glass is formed, it typically undergoes a rapid cooling phase, often called quenching.

This rapid drop in temperature locks the molecular structure in place before it can settle, generating significant internal thermal stress.

The Holding Phase

The annealing furnace interrupts the cooling process. It holds the glass at a constant temperature, known as the annealing point.

As noted in standard processing (e.g., at 210°C), holding the glass here allows the internal strains to relax without melting the sample.

Controlled Cooling Rates

Once the stress is relieved, the furnace does not simply turn off. It lowers the temperature at a strictly controlled rate.

This slow descent prevents the re-introduction of stress that would occur if the glass were exposed to ambient air too quickly.

Why This Process is Non-Negotiable

Preventing Spontaneous Failure

Glass that has not been annealed is mechanically unstable.

The tension within the material can be so high that the sample shatters spontaneously, even without external force.

Enabling Mechanical Processing

Most glass components require cutting, grinding, or polishing after formation.

If internal stresses remain, the physical force of these tools will cause the glass to crack immediately. Annealing ensures the structural stability required for this work.

Improving Physical Properties

Beyond basic durability, annealing homogenizes the material.

This results in better optical uniformity and consistent physical properties, which are essential for high-quality doped or composite glass applications.

Understanding the Trade-offs

Time Intensity

Annealing is not a quick fix; it is a bottleneck in the production line.

Depending on the thickness and type of glass, the process can take from several hours to several days to ensure complete stabilization.

Strict Temperature Sensitivity

Precision is paramount; there is little room for error.

If the furnace temperature is set too low, stresses will not release; if set too high, the glass may deform. You must accurately identify the transition temperature of your specific material.

Making the Right Choice for Your Goal

To maximize the utility of your precision annealing furnace, align your process with your specific objectives:

- If your primary focus is Structural Integrity: Ensure the holding time at the annealing point is sufficient to fully relieve the specific level of stress generated by your quenching method.

- If your primary focus is Optical Quality: Prioritize an extremely slow cooling rate after the holding phase to ensure maximum uniformity across the glass body.

- If your primary focus is Complex Composites: Verify that the annealing temperature accounts for all materials in the matrix to prevent thermal mismatch.

The precision annealing furnace is the essential bridge between a volatile raw melt and a reliable, usable glass component.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Thermal Stabilization | Holds glass at a specific transition temperature (e.g., 210°C). | Relieves internal molecular strain. |

| Controlled Cooling | Slowly reduces temperature at a programmed rate. | Prevents new stresses and spontaneous failure. |

| Structural Integrity | Homogenizes the material matrix. | Enables safe grinding, cutting, and polishing. |

| Optical Quality | Ensures uniform physical properties. | Critical for high-quality doped or composite glass. |

Elevate Your Glass Processing Precision with KINTEK

Don’t let internal stresses compromise your research or production. KINTEK provides industry-leading thermal solutions designed to transform volatile melts into stable, high-performance materials. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces that are fully customizable to your specific annealing points and cooling profiles.

Whether you are working with complex composites or high-purity optical glass, our precision equipment ensures the structural integrity and uniformity your project demands.

Ready to optimize your thermal stabilization process?

Visual Guide

References

- Ashleigh M. Chester, Thomas D. Bennett. Loading and thermal behaviour of ZIF-8 metal–organic framework-inorganic glass composites. DOI: 10.1039/d4dt00894d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What industries commonly use retort furnaces and for what purposes? Unlock High-Purity Thermal Processing

- Why is a reactive atmosphere sometimes required in heat treatment? Achieve Superior Surface Hardness and Durability

- What are the five key components of atmosphere furnaces? Master Controlled Heat Treatment for Superior Results

- Why is argon's inert nature important in furnace applications? Protect Materials from High-Temperature Reactions

- In what settings are controlled atmosphere furnaces commonly used? Essential for High-Purity Material Processing

- What role does an argon atmosphere furnace play during the heat treatment process of Ti-6Al-7Nb alloys? Expert Guide

- What is the purpose of sulfur-enriched environments for MoS2-WS2 heterojunctions? Ensure Optimal Crystal Stoichiometry

- What is the difference between a vacuum furnace and an atmosphere furnace? Choose the Right Environment for Your Process