In short, retort furnaces are workhorses in industries like metallurgy, ceramics, electronics, and chemical processing. Their primary purpose is to perform high-temperature thermal processes—such as annealing, sintering, and brazing—within a tightly controlled atmosphere, which is essential for achieving high material purity and specific properties.

The defining feature of a retort furnace is not merely its ability to generate high heat, but its use of a sealed inner chamber, or retort. This allows for complete control over the internal atmosphere, enabling processes that are impossible in open-air furnaces where oxygen would ruin the material.

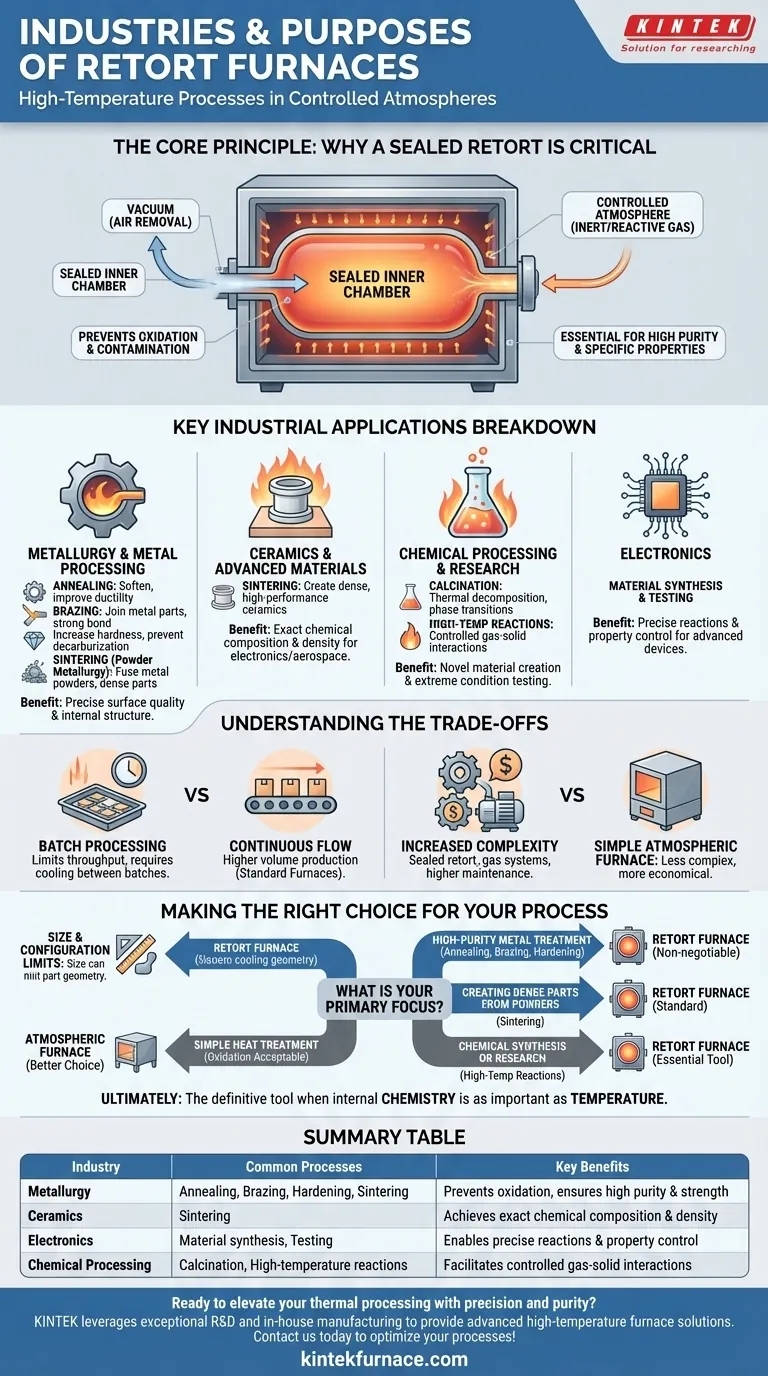

The Core Principle: Why a Sealed Retort is Critical

A standard furnace heats materials in ambient air. A retort furnace, however, places the material inside a sealed vessel, typically made of high-temperature alloy or ceramic.

Controlling the Environment

This sealed design allows operators to first remove the ambient air, creating a vacuum. They can then backfill the retort with a specific gas.

This creates a controlled atmosphere. This atmosphere could be inert (like argon or nitrogen) to prevent chemical reactions, or it could be reactive (like hydrogen) to actively participate in the process.

Preventing Oxidation and Contamination

The primary benefit of this control is the prevention of oxidation. At high temperatures, most metals will rapidly react with oxygen, forming brittle oxides that degrade their structural integrity and performance.

By removing oxygen, a retort furnace ensures the material remains pure and maintains its desired metallic properties.

Key Industrial Applications Breakdown

The ability to control the atmosphere unlocks several critical industrial processes that are impossible or impractical in a standard furnace.

Metallurgy and Metal Processing

This is one of the largest fields for retort furnace use. They are essential for treating metals where surface quality and internal structure are paramount.

Common processes include:

- Annealing: Heating and cooling metal to soften it and improve its ductility. A controlled atmosphere prevents surface scaling.

- Brazing: Joining two metal parts using a filler metal. An inert atmosphere ensures the brazing alloy flows cleanly and forms a strong, pure bond without oxides.

- Hardening: Heat treating steel or other alloys to increase their hardness. Precise atmospheric control prevents unwanted decarburization (loss of carbon) from the surface.

- Powder Metallurgy: Fusing metal powders together just below their melting point, a process called sintering. This requires a controlled atmosphere to create dense, strong parts from powders.

Ceramics and Advanced Materials

Retort furnaces are used to create dense, high-performance ceramics and composite materials from powders.

During sintering, the controlled atmosphere prevents any unwanted chemical reactions between the furnace air and the ceramic material, ensuring the final product has the exact chemical composition and density required for applications in electronics or aerospace.

Chemical Processing and Research

In the chemical industry, retort furnaces serve as high-temperature reactors. The sealed retort allows for processes where specific gases must react with a solid material.

An example is calcination, a process that uses heat to cause thermal decomposition or phase transitions in a material. In research, they are used for everything from creating novel materials to testing material behavior under extreme conditions.

Understanding the Trade-offs

While powerful, retort furnaces are not the universal solution for all heating applications. Their specialized nature comes with specific limitations.

Batch Processing vs. Continuous Flow

Most retort furnaces operate on a batch basis. A load is placed inside, the retort is sealed and purged, the heating cycle runs, and then the system cools before the next batch. This can limit throughput compared to continuous belt furnaces used for high-volume production.

Increased Complexity and Cost

The need for a sealed retort, vacuum pumps, and gas management systems adds significant complexity and cost compared to a simple atmospheric box furnace. Maintenance requirements are also higher.

Size and Configuration Limits

The physical retort vessel itself can impose limitations on the size and geometry of the parts that can be processed. Very large or awkwardly shaped components may require custom-built or alternative types of furnaces.

Making the Right Choice for Your Process

Selecting the correct thermal processing technology depends entirely on your material and desired outcome.

- If your primary focus is high-purity metal treatment: A retort furnace is non-negotiable for processes like annealing, brazing, and hardening where preventing oxidation is critical.

- If your primary focus is creating dense parts from powders: A retort furnace is the standard for sintering both powdered metals and advanced ceramics.

- If your primary focus is chemical synthesis or research: The controlled atmosphere of a retort furnace provides an essential tool for high-temperature reactions and material experiments.

- If your primary focus is simple heat treatment where surface oxidation is acceptable: A less complex and more economical atmospheric furnace is likely the better choice.

Ultimately, a retort furnace is the definitive tool when the chemistry inside the furnace is just as important as the temperature.

Summary Table:

| Industry | Common Processes | Key Benefits |

|---|---|---|

| Metallurgy | Annealing, Brazing, Hardening, Sintering | Prevents oxidation, ensures high purity and strength |

| Ceramics | Sintering | Achieves exact chemical composition and density |

| Electronics | Material synthesis, Testing | Enables precise reactions and property control |

| Chemical Processing | Calcination, High-temperature reactions | Facilitates controlled gas-solid interactions |

Ready to elevate your thermal processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in metallurgy, ceramics, electronics, or chemical processing, our retort furnaces ensure controlled atmospheres for superior results. Contact us today to discuss how we can optimize your processes and deliver reliable, high-performance solutions!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments