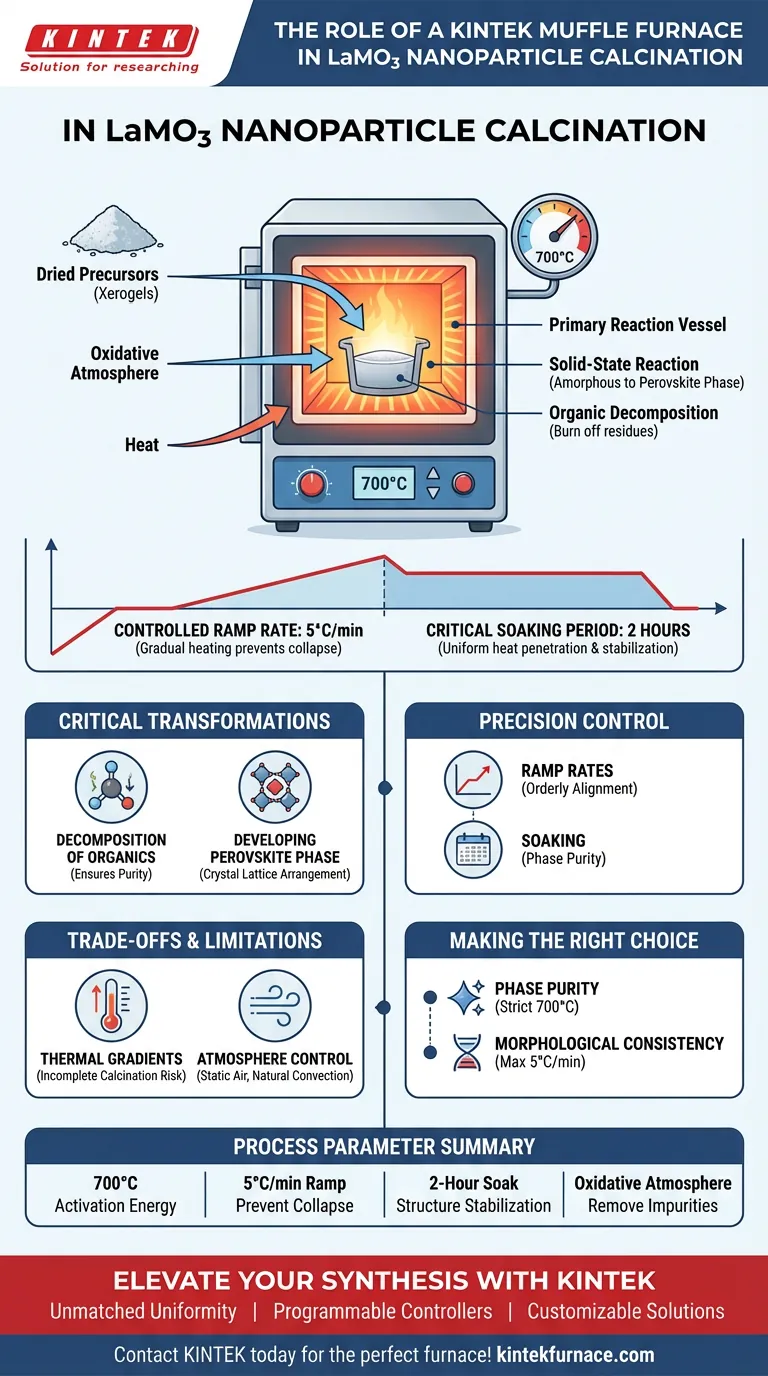

A laboratory muffle furnace functions as the primary reaction vessel for transforming dried precursors into crystalline LaMO3 nanoparticles (where M = Cr, Mn, or Co). It provides the high-temperature oxidative environment required to heat samples to exactly 700°C at a controlled rate of 5°C per minute, followed by a critical 2-hour soaking period.

The muffle furnace drives the solid-state reaction that converts amorphous xerogels into pure-phase perovskite crystals. By precisely controlling the thermal profile, it ensures the complete decomposition of organic residues while stabilizing the final nanoparticle structure.

Facilitating Critical Chemical Transformations

The muffle furnace is not simply a heater; it is the environment where the material's chemical identity is finalized.

Decomposition of Organic Components

The synthesis of LaMO3 nanoparticles typically begins with a precursor containing organic elements, often in the form of a xerogel.

The muffle furnace provides the oxidative atmosphere necessary to burn off these organic binders and residues completely. Without this step, carbonaceous impurities would remain, compromising the purity of the final nanomaterial.

Developing the Perovskite Crystal Phase

The primary function of the furnace is to supply the energy required for crystallization.

At 700°C, the amorphous precursor undergoes a solid-state reaction, rearranging its atomic structure into the ordered lattice of the perovskite phase. This thermal treatment is what physically distinguishes the final LaMO3 nanoparticle from the initial dried gel.

Ensuring Phase Purity

Achievement of a pure crystalline phase is dependent on consistent heat application.

The furnace's high-precision temperature control ensures the entire sample reaches the activation energy needed for the reaction, preventing the formation of secondary or incomplete phases.

The Role of Precision Control Parameters

The quality of the nanoparticles is dictated by the specific thermal profile executed by the furnace.

Controlled Ramp Rates

The furnace must adhere to a strict ramp rate of 5°C per minute.

Heating too quickly can cause structural collapse or uneven reaction rates within the material. A controlled ramp allows for the gradual release of volatiles and the orderly alignment of the crystal lattice.

The Importance of the Soaking Period

Once the target temperature is reached, the furnace maintains a 2-hour soak.

This dwell time allows the heat to penetrate the sample core, ensuring that the solid-state reaction is completed uniformly throughout the batch. It stabilizes the crystal structure before the cooling process begins.

Understanding the Trade-offs

While the muffle furnace is the standard tool for this process, users must be aware of inherent limitations to ensure data validity.

Thermal Gradients

Standard muffle furnaces may experience temperature variations between the center of the chamber and the walls.

If the sample is placed too close to the heating elements or the door, the actual temperature may deviate from the 700°C setpoint, potentially resulting in incomplete calcination or uneven grain growth.

Atmosphere Control

Most basic muffle furnaces operate in a static air environment.

While this is ideal for the oxidative requirements of LaMO3 synthesis, it limits the ability to actively flush reaction byproducts. Users rely on natural convection to remove the gases evolved during organic decomposition.

Making the Right Choice for Your Goal

The calcination protocol is the lever you pull to adjust the final characteristics of your LaMO3 nanoparticles.

- If your primary focus is Phase Purity: Adhere strictly to the 700°C setpoint, as lower temperatures may fail to fully trigger the transformation into the perovskite structure.

- If your primary focus is Morphological Consistency: Ensure the ramp rate does not exceed 5°C/min to prevent rapid gas evolution from damaging the developing porous structure.

Precision in your thermal processing parameters is the single most important factor in reproducing high-quality nanoparticle synthesis.

Summary Table:

| Process Parameter | Role in LaMO3 Calcination | Impact on Nanoparticle Quality |

|---|---|---|

| 700°C Temperature | Provides activation energy for solid-state reaction | Ensures transformation from amorphous to perovskite phase |

| 5°C/min Ramp Rate | Gradual release of volatiles and organic residues | Prevents structural collapse and promotes orderly crystallization |

| 2-Hour Soaking | Uniform heat penetration and structure stabilization | Guarantees phase purity and completes solid-state transformations |

| Oxidative Atmosphere | Burns off organic binders and carbon residues | Eliminates impurities to produce high-purity crystalline powder |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the backbone of high-quality LaMO3 nanoparticle production. KINTEK provides industry-leading muffle, tube, and vacuum furnace systems specifically designed to handle the rigorous demands of calcination and solid-state reactions.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces offer:

- Unmatched Temperature Uniformity: Eliminate thermal gradients for consistent phase purity.

- Programmable Logic Controllers: Easily set precise ramp rates (like 5°C/min) and soaking periods.

- Customizable Solutions: Tailor chamber sizes and atmospheric controls to your unique research needs.

Don't let inconsistent heating compromise your research results. Contact KINTEK today to find the perfect furnace for your laboratory!

Visual Guide

References

- Hongquan Zhao, Songtao Dong. Electrochemical Properties of LaMO3(M=Cr, Mn, and Co) Perovskite Materials. DOI: 10.3390/coatings14010147

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role do muffle furnaces play in sintering 3D-printed beta-TCP? Optimize Your Bioceramic Results

- What are the dimensions and capacity of the muffle furnace's chamber? Optimize Your Lab's Heating Efficiency

- What features are included in the temperature control console of box furnaces? Achieve Precision and Repeatability in Thermal Processing

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab

- What function does a high-temperature muffle furnace serve in the preparation of Ni-doped LaFeO3 gas-sensing materials?

- What is the purpose of using a high-temperature box resistance furnace for Fe-g-C3N4? Master Thermal Polycondensation

- What is the role of a high-temperature calcination furnace in preparing ultra-fine oxide nanopowders? Master Purity

- What role does a muffle furnace play in ZnO-doped CuO synthesis? Master Precision Nanocomposite Production