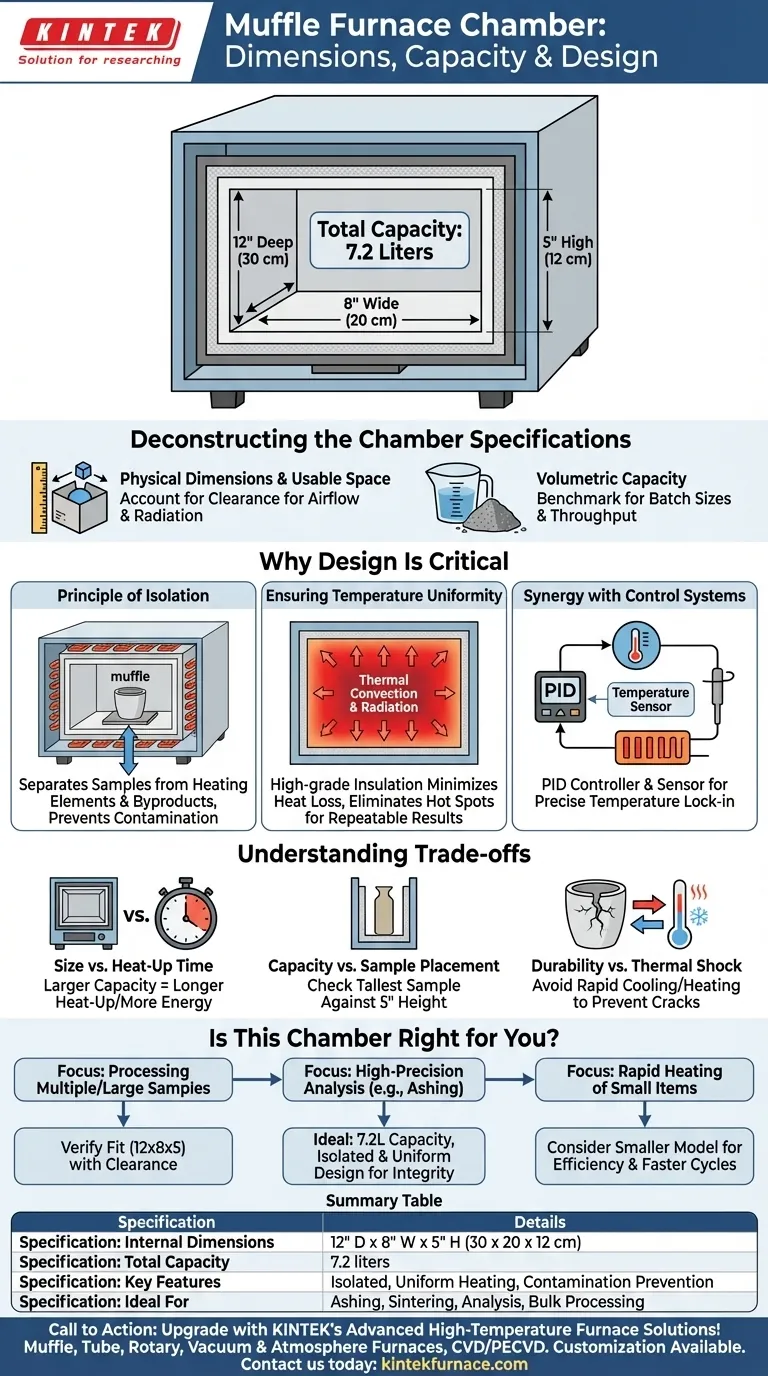

The muffle furnace chamber has internal dimensions of 12 inches deep, 8 inches wide, and 5 inches high (30 x 20 x 12 cm). This provides a total internal volume, or capacity, of 7.2 liters. These measurements define the usable workspace available for your samples or materials.

The physical size of a furnace chamber is only the starting point. The true value lies in understanding how its design—specifically its isolation and insulation—creates a controlled environment for achieving the uniform temperatures and sample purity essential for precise scientific and industrial work.

Deconstructing the Chamber Specifications

To determine if this furnace is right for your needs, it's crucial to look beyond the numbers and understand what they mean in a practical context.

Physical Dimensions and Usable Space

The stated dimensions of 12" D x 8" W x 5" H define the absolute internal boundaries of the heating chamber. When planning your process, always account for necessary clearance around your items.

Proper airflow and heat radiation are critical for uniform heating. Ensure your crucibles, parts, or samples do not touch the chamber walls and have space between them.

Volumetric Capacity

The 7.2-liter capacity is the total internal volume. This metric is most useful for estimating the furnace's throughput for bulk materials, powders, or a large number of small items. It serves as a benchmark for comparing batch sizes across different models.

Why the Chamber's Design Is Critical

A muffle furnace is more than a simple hot box. Its chamber is specifically engineered to deliver reliable and uncontaminated heating.

The Principle of Isolation

The core concept of a muffle furnace is the "muffle"—an isolated inner chamber. This design separates your samples from the heating elements and any combustion byproducts.

This isolation is crucial for preventing chemical reactions or contamination, ensuring the integrity and purity of your sample. It is essential for sensitive processes like ashing, sintering, or materials analysis.

Ensuring Temperature Uniformity

The chamber is built with high-grade insulation, such as dense glass wool or ceramic blankets. This minimizes heat loss and, more importantly, helps create a highly uniform temperature zone.

By combining thermal convection and radiation within a well-insulated space, the furnace eliminates hot spots. This uniformity ensures that your entire sample experiences the exact same thermal conditions, leading to accurate and repeatable results.

The Synergy with Control Systems

The physical chamber works in tandem with the furnace's electronic controls. A PID (Proportional-Integral-Derivative) controller and a temperature sensor (like a J-type) constantly monitor and adjust the power sent to the heaters.

The insulated chamber's ability to retain heat smoothly allows the PID controller to make fine-tuned adjustments, locking in the precise temperature required for your process.

Understanding the Trade-offs

Every design involves compromises. Being aware of them helps you make a fully informed decision.

Size vs. Heat-Up Time

A larger 7.2-liter chamber provides excellent capacity but may require more time and energy to reach its target temperature compared to a smaller, more compact model.

Capacity vs. Sample Placement

While the volume is substantial, the 5-inch height may be a limiting factor for tall items. Always check your tallest sample against the chamber's smallest dimension.

Durability vs. Thermal Shock

The ceramic materials used for muffle chambers are extremely durable at high temperatures but can be susceptible to thermal shock. Avoid placing cold items into a very hot furnace or cooling the chamber too rapidly, as this can cause cracks.

Is This Chamber Right for Your Application?

Use the following guidelines to match the furnace's capabilities to your primary goal.

- If your primary focus is processing multiple or large samples: Verify that your materials, along with necessary clearances, will fit comfortably within the 12" x 8" x 5" workspace.

- If your primary focus is high-precision analysis (e.g., ashing): The 7.2L capacity, combined with the isolated and uniformly heated chamber design, is ideal for protecting sample integrity and achieving accurate results.

- If your primary focus is rapid heating of small items: This furnace is highly capable, but a smaller model could offer greater energy efficiency and faster heat-up cycles for very small batches.

Understanding these chamber specifications empowers you to select a furnace that performs not just as a heater, but as a precise instrument for your work.

Summary Table:

| Specification | Details |

|---|---|

| Internal Dimensions | 12" D x 8" W x 5" H (30 x 20 x 12 cm) |

| Total Capacity | 7.2 liters |

| Key Features | Isolated chamber, uniform heating, contamination prevention |

| Ideal For | Ashing, sintering, materials analysis, bulk processing |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Benefit from strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis