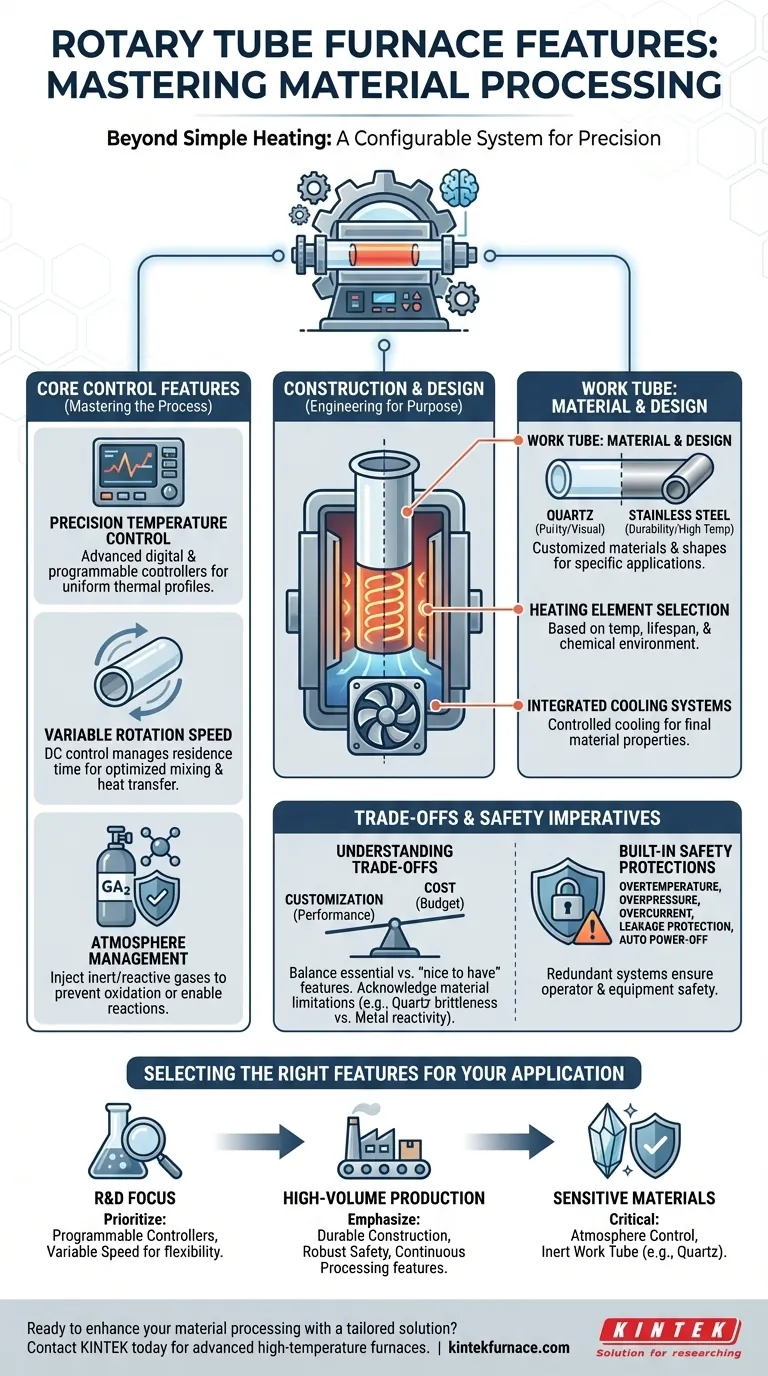

Beyond simple heating, a modern rotary tube furnace is a highly configurable system designed for precise material processing. Key features typically include advanced temperature and rotation controls, options for atmosphere management, and a variety of customizable construction materials and safety systems to suit specific industrial or laboratory applications.

The core principle is not the quantity of features, but how they are integrated to master a specific processing challenge. A furnace's true value is realized when its controls, materials, and safety systems are tailored to achieve precise, uniform, and repeatable results for your unique material.

Mastering the Process: Core Control Features

The primary function of a rotary tube furnace is to apply heat uniformly to a moving material. The features in this category give you direct control over that process, transforming the furnace from a simple heater into a precision instrument.

Precision Temperature Control

Modern furnaces use advanced digital controllers for exceptional temperature accuracy. This ensures the entire hot zone maintains a uniform temperature, which is critical for consistent results.

Many systems include programmable controllers that allow you to create complex thermal profiles. For example, you can program a series of heating, soaking, and cooling steps—often supporting dozens of segments—to execute a specific thermal recipe automatically.

Variable Rotation Speed

The ability to adjust the rotation of the tube is a fundamental feature. A DC variable speed control allows you to manage the material's residence time inside the hot zone.

Slower speeds increase exposure time, while faster speeds can improve mixing. This control is essential for optimizing heat transfer and achieving the desired outcome for different powders and granular materials.

Atmosphere Management

For materials that are sensitive to oxygen or require a specific gaseous environment, atmosphere control is a critical option.

This feature allows for the introduction of inert gases (like nitrogen or argon) or reactive gases into the work tube, preventing unwanted oxidation and enabling specific chemical reactions during the heating process.

Engineering for Purpose: Construction & Design Features

The physical construction of the furnace dictates its durability, temperature limits, and suitability for different materials. These features are chosen based on the demands of the application.

The Work Tube: Material and Design

The work tube is the heart of the furnace. It can be made from different materials, most commonly quartz or stainless steel. Quartz is ideal for applications requiring high purity and visual monitoring, while stainless steel offers greater durability and can often withstand higher temperatures.

The size and shape of the tube are also frequently customized to accommodate specific material volumes and flow characteristics.

Heating Element Selection

The heating elements are responsible for generating the thermal energy. The type of element used is determined by the furnace's maximum required operating temperature, its expected lifespan, and the chemical environment inside the furnace.

Integrated Cooling Systems

While heating is the primary function, controlled cooling is often just as important for the final properties of the material. Optional cooling systems can be integrated to bring the material's temperature down at a controlled rate after it exits the hot zone.

Understanding the Trade-offs and Safety Imperatives

Selecting the right features involves balancing performance with cost and acknowledging material limitations. At the same time, safety features are non-negotiable.

Customization vs. Cost

Every added feature or choice of a more exotic material will impact the final cost. The key is to distinguish between features that are essential for your process and those that are merely "nice to have."

A clear understanding of your process requirements prevents over-engineering and ensures a better return on investment.

Material Limitations

The choice of work tube material introduces trade-offs. Quartz is chemically inert but can be brittle and susceptible to thermal shock. Metal tubes are more robust but may introduce trace contaminants or react with certain process materials at high temperatures.

Built-in Safety Protections

Operator and equipment safety are paramount. Modern furnaces are equipped with multiple, redundant safety systems to prevent accidents.

These essential protections include safeguards for overtemperature, overpressure, and overcurrent. A leakage protection switch and automatic power-off mechanisms are also standard features to ensure safe operation.

Selecting the Right Features for Your Application

To specify the right furnace, you must first define your goal. Different applications demand different feature sets.

- If your primary focus is research and development: Prioritize programmable temperature controllers and variable rotation speed for maximum process flexibility and experimentation.

- If your primary focus is high-volume industrial production: Emphasize durable construction materials, robust safety systems, and features that enable continuous, automated processing.

- If your primary focus is processing sensitive or reactive materials: Atmosphere control systems and the choice of an inert work tube material (like quartz) are your most critical features.

Ultimately, defining your process requirements is the first and most critical step in specifying a rotary tube furnace that delivers results.

Summary Table:

| Feature Category | Key Components | Benefits |

|---|---|---|

| Core Control | Precision temperature control, Variable rotation speed, Atmosphere management | Enables uniform heating, precise process control, and handling of sensitive materials |

| Construction & Design | Work tube materials (e.g., quartz, stainless steel), Heating elements, Cooling systems | Ensures durability, high-temperature performance, and tailored material compatibility |

| Safety & Trade-offs | Overtemperature, overpressure, overcurrent protections, Material limitations, Cost considerations | Provides reliable operation, prevents accidents, and balances performance with budget |

Ready to enhance your material processing with a tailored rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how we can optimize your laboratory or industrial processes with reliable, efficient solutions!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What level of process control do rotary tube furnaces provide? Achieve Precise Thermal Processing for Uniform Results

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency

- What materials are rotary tube furnaces typically constructed from? Choose the Right Tube for Your Process

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating