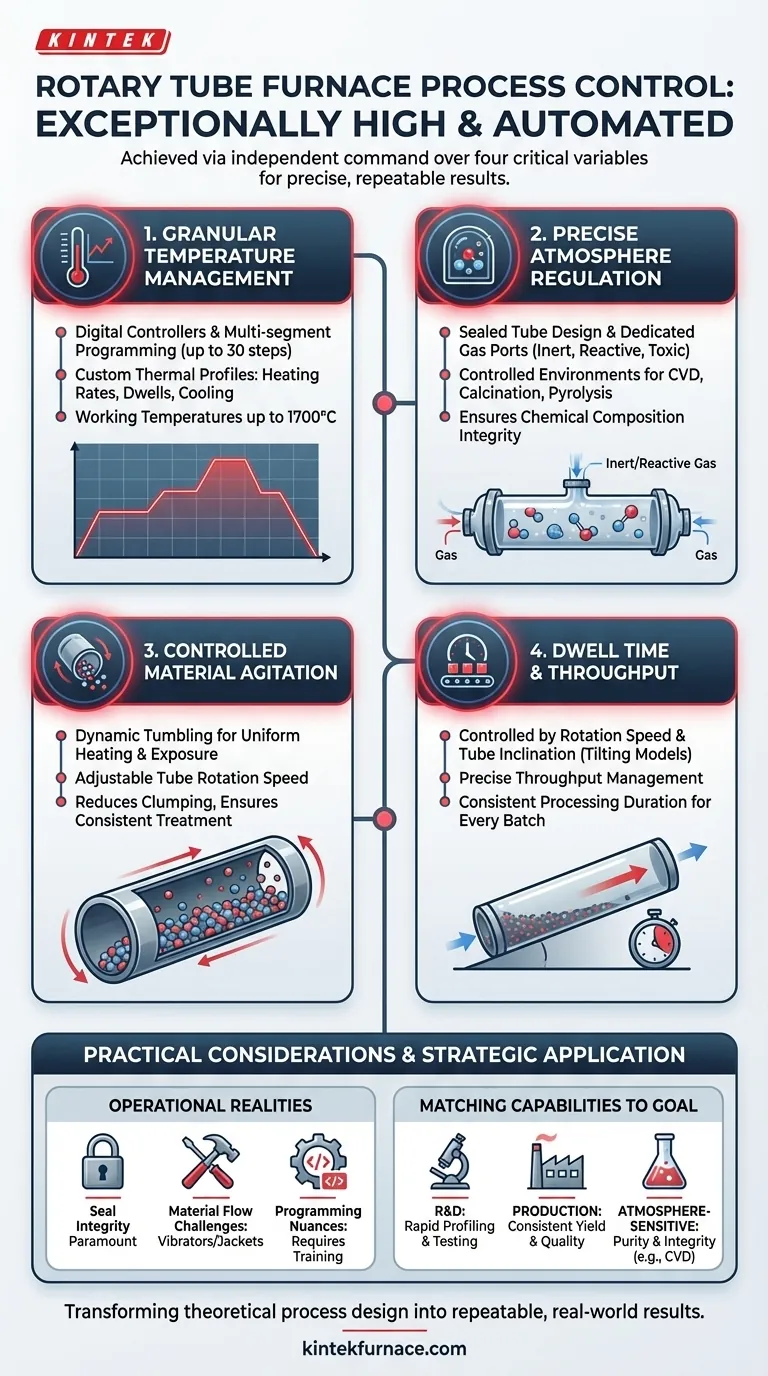

In short, rotary tube furnaces provide an exceptionally high level of process control. This is achieved by giving operators independent and automated command over the four critical variables of thermal processing: temperature, atmosphere, material agitation, and time.

The core value of a rotary tube furnace is its ability to transform a theoretical process into a physical reality with high fidelity and repeatability. The extensive controls are not just features; they are the mechanisms that ensure every particle of a material receives the exact same treatment, leading to uniform and predictable results.

The Pillars of Process Control

A rotary tube furnace's effectiveness stems from its precise management of several interconnected physical and chemical parameters. Understanding these pillars is key to leveraging the technology for your specific application.

Granular Temperature Management

The foundation of control is managing heat. Modern rotary tube furnaces use advanced digital controllers that allow for precise temperature regulation, often with uniformity across the entire heated zone.

Many systems feature multi-segment programming, with some offering up to 30 distinct steps. This allows you to design a custom thermal profile with specific heating rates, holding periods (dwells), and cooling stages, all executed automatically.

These furnaces can be specified for a wide range of applications, with maximum working temperatures available up to 1700°C.

Precise Atmosphere Regulation

For many advanced materials, the processing atmosphere is as critical as the temperature. Rotary tube furnaces excel here due to their sealed tube design.

Superior sealing systems and dedicated gas handling ports (such as 1/4" inert gas inlets and KF25 outgassing ports) enable a tightly controlled environment. This allows for processing in inert atmospheres (like argon or nitrogen), reactive atmospheres (like oxygen or hydrogen), or even with toxic and flammable gases.

This level of control is essential for applications like Chemical Vapor Deposition (CVD), calcination, and pyrolysis, where atmospheric integrity directly impacts the final product's chemical composition.

Controlled Material Agitation

The furnace's defining feature—the rotation of the tube—provides dynamic and uniform heating. By continuously tumbling the material, the system ensures that every particle is equally exposed to the heat source and the process atmosphere.

The tube rotation speed is a key adjustable parameter. Faster rotation can increase mixing for certain materials, while slower rotation can increase the residence time within the hottest zone.

Dwell Time and Throughput

The time a material spends undergoing treatment is a critical variable. In a rotary tube furnace, this dwell time is controlled by a combination of the tube's rotation speed and its angle of inclination (on tilting models).

By adjusting these factors, you can precisely manage the throughput of the furnace, ensuring each batch of material receives the exact processing duration required for consistent results.

Understanding the Practical Considerations

While powerful, achieving optimal control requires understanding the system's operational realities and potential challenges.

Seal Integrity is Paramount

The furnace's exceptional atmosphere control is entirely dependent on the quality and maintenance of its seals. Any degradation or failure of the sealing system will compromise the process environment, potentially ruining a batch and posing a safety risk if using hazardous gases.

Material Flow Challenges

The dynamic tumbling motion is ideal for loose powders and granules. However, certain materials can present challenges.

High-viscosity or sticky organic materials may clump or adhere to the tube walls. Optional features like hammer vibrators exist specifically to counteract this issue and maintain consistent material flow.

Similarly, processes that create condensable byproducts (like tar) may require optional heating jackets on the furnace ends to prevent buildup and blockages.

The Nuances of Programming

The ability to program complex, 30-segment thermal profiles is a significant advantage. However, this power requires careful setup.

An incorrectly programmed profile—even a small error in a heating rate or dwell time—can lead to inconsistent or failed batches. Proper operator training on the control system is essential to harness its full potential.

Matching Control Capabilities to Your Goal

The right way to leverage the furnace's control system depends entirely on your end goal.

- If your primary focus is research and development: Leverage the multi-segment programming to rapidly test different thermal profiles and pinpoint the optimal parameters for a new material or process.

- If your primary focus is consistent production: Emphasize the automated controls for temperature, atmosphere, and dwell time to ensure every batch is identical, maximizing yield and quality.

- If your primary focus is atmosphere-sensitive processes (like CVD): The advanced sealing and gas handling systems are your most critical features, ensuring the chemical purity and integrity of your final product.

Ultimately, the furnace's granular control empowers you to move from theoretical process design to repeatable, real-world results.

Summary Table:

| Control Parameter | Key Features | Benefits |

|---|---|---|

| Temperature | Digital controllers, multi-segment programming (up to 30 steps), up to 1700°C | Precise thermal profiles, uniform heating, repeatable results |

| Atmosphere | Sealed tube design, gas handling ports (e.g., inert/reactive gases) | Controlled chemical environments, essential for CVD, calcination |

| Material Agitation | Adjustable tube rotation speed | Dynamic mixing, uniform particle exposure, reduced clumping |

| Dwell Time | Rotation speed and tube inclination control | Managed throughput, consistent processing duration |

Ready to elevate your lab's thermal processing with tailored solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Rotary Tube Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced efficiency and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing