At its core, a modern porcelain furnace user interface is designed for precise control and repeatability. Key features almost always include a digital touchscreen, the ability to create and save custom firing programs, real-time monitoring of the firing cycle, and a library of pre-set programs for common materials.

The user interface is not just a screen; it is the critical link between the technician's knowledge and the furnace's mechanical precision. A well-designed UI empowers the user to achieve consistent, high-quality results with minimal friction.

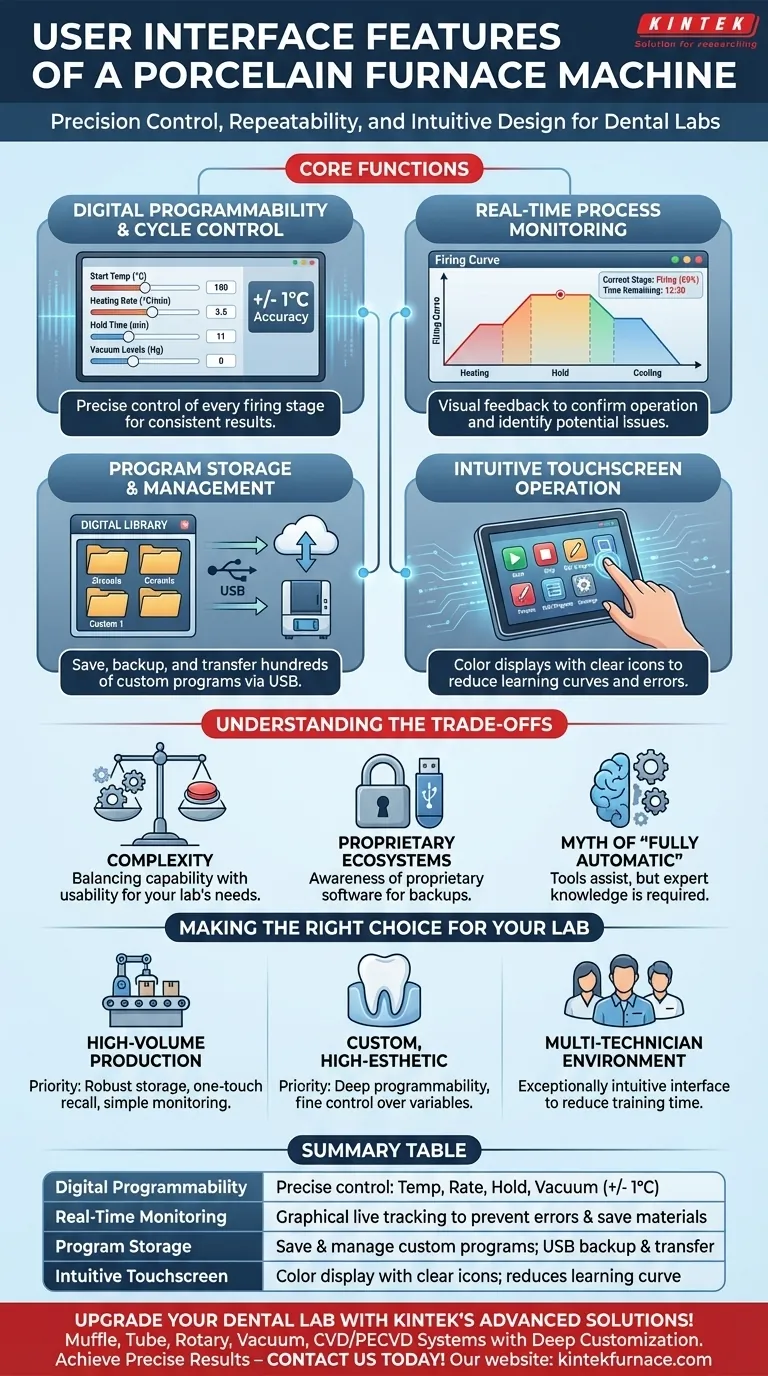

The Core Functions of a Modern Furnace Interface

The goal of any furnace UI is to translate the complex requirements of dental ceramics into a simple, error-resistant workflow. This is accomplished through several key functions.

Digital Programmability and Cycle Control

This is the most critical feature. The interface allows technicians to precisely program every stage of the firing cycle, including start temperature, heating rate (degrees per minute), hold time, and vacuum levels.

Modern systems offer extreme precision, often maintaining temperature accuracy within +/- 1 degree Celsius, which is essential for the aesthetic and structural integrity of the final restoration.

Real-Time Process Monitoring

A graphical display on the touchscreen shows the current stage of the firing cycle in real-time.

This visual feedback allows the technician to confirm the furnace is operating as expected and provides an opportunity to identify potential issues before a cycle is complete, saving time and materials.

Program Storage and Management

Furnaces can store dozens or even hundreds of firing programs. Technicians can save custom programs for specific materials or restoration types, ensuring perfect consistency every time that job is run.

Many units also feature USB connectivity, allowing for the backup, restoration, and transfer of firing programs between machines, which is invaluable for growing labs or maintaining standards across multiple locations.

Intuitive Touchscreen Operation

The industry has moved almost entirely to color touchscreen displays. An intuitive UI with clear icons and logical menus significantly reduces the learning curve for new technicians and minimizes the risk of user error.

Understanding the Trade-offs

While modern interfaces are powerful, it's important to understand their potential limitations. Choosing a machine requires balancing capability with usability.

Complexity vs. Simplicity

An interface with vast customization options can be powerful for expert technicians working with unique materials. However, this same complexity can be overwhelming and lead to errors in a high-volume lab that prioritizes speed and standardization.

Conversely, an overly simplistic interface may be easy to use but lack the fine-grained control needed for complex, high-esthetic cases.

Proprietary Ecosystems

Be aware that some manufacturers may use proprietary software or file formats for program backups via USB. This can make it difficult to migrate programs to a furnace from a different brand in the future.

The Myth of "Fully Automatic"

No matter how advanced the interface, it is a tool that assists, but does not replace, the skill of the dental technician. Pre-set programs are an excellent starting point, but expert knowledge is still required to adjust for variables and achieve optimal results.

Making the Right Choice for Your Lab

The ideal furnace interface depends entirely on your specific operational needs and goals.

- If your primary focus is high-volume production: Prioritize a furnace with robust program storage, easy one-touch recall of presets, and a simple, clear monitoring screen.

- If your primary focus is custom, high-esthetic restorations: Look for an interface with deep programmability, allowing fine control over every variable in the firing cycle.

- If your primary focus is a multi-technician environment: Choose a furnace with an exceptionally intuitive, easy-to-learn interface to reduce training time and ensure consistency across all users.

Ultimately, the right user interface makes technology feel invisible, allowing you to focus on the artistry and science of the restoration.

Summary Table:

| Feature | Description |

|---|---|

| Digital Programmability | Precise control of temperature, heating rate, hold time, and vacuum levels with +/- 1°C accuracy. |

| Real-Time Monitoring | Graphical display for live tracking of firing cycles to prevent errors and save materials. |

| Program Storage | Save and manage custom programs with USB connectivity for backup and transfer between machines. |

| Intuitive Touchscreen | Color display with clear icons and menus to reduce learning curves and minimize user errors. |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Achieve precise, repeatable results—contact us today to learn how our tailored solutions can enhance your productivity and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations