The vacuum arc furnace is the indispensable tool for processing Ti-Zr-Nb alloys, acting as a barrier against chemical degradation. Its critical role is to provide a controlled environment that simultaneously prevents oxidation of reactive elements and generates the extreme heat necessary to melt refractory metals without introducing impurities.

The primary value of a vacuum arc furnace lies in its ability to isolate highly reactive metals like titanium, zirconium, and niobium from atmospheric oxygen and nitrogen. By combining a vacuum or argon environment with a water-cooled copper crucible, it ensures the alloy remains chemically pure and achieves an atomic-level uniform distribution through multiple re-melting cycles.

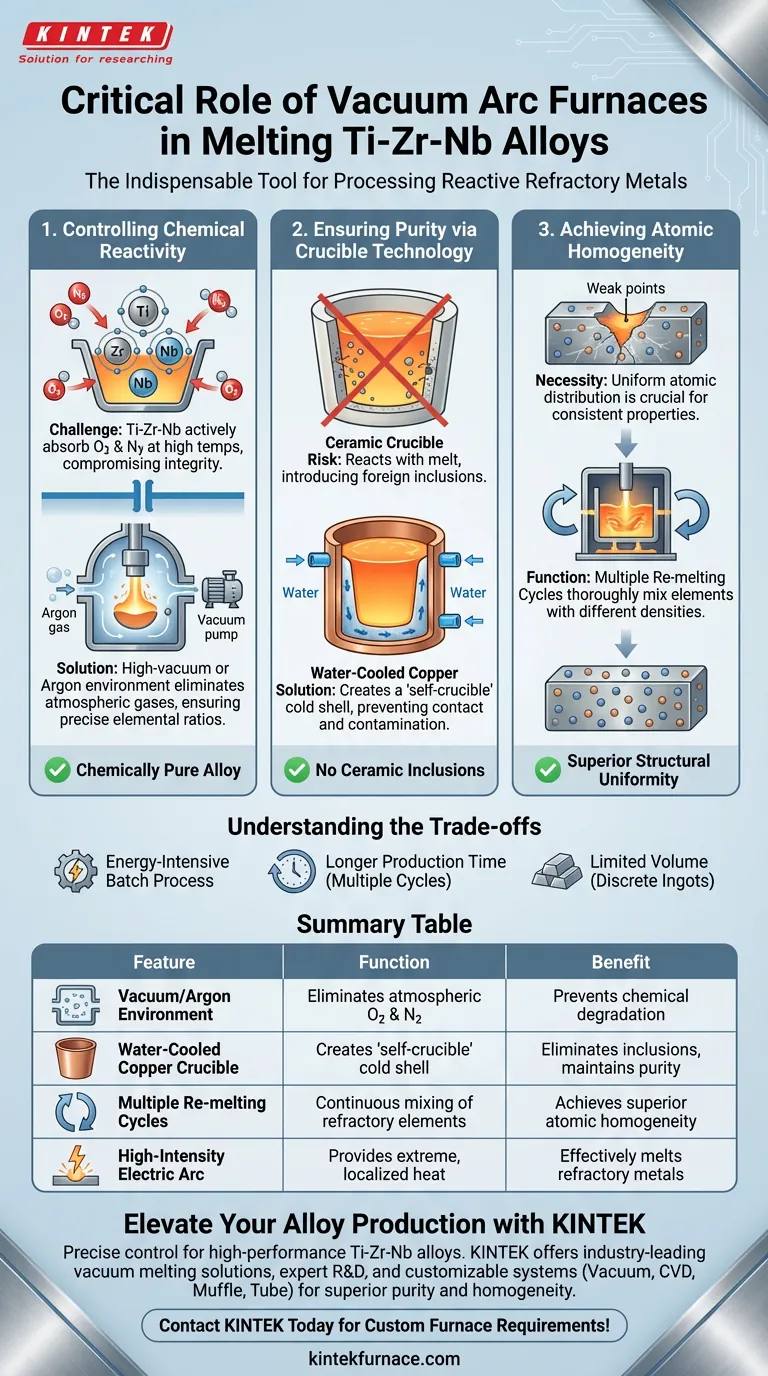

Controlling Chemical Reactivity

The Challenge of Refractory Metals

Ti-Zr-Nb alloys consist of refractory metals that possess high melting points and extreme chemical reactivity.

When these metals are heated, they actively absorb oxygen and nitrogen from the air. This contamination compromises the structural integrity and performance of the final alloy.

The Role of the Vacuum Environment

The furnace eliminates this risk by operating in a high-vacuum state or under the protection of inert argon gas.

This controlled atmosphere effectively blocks the interaction between the metal melt and atmospheric gases. Consequently, the alloy retains the precise elemental ratios designed for the application.

Ensuring Purity via Crucible Technology

Limitations of Ceramics

Traditional ceramic crucibles are unsuitable for melting Ti-Zr-Nb alloys due to the high temperatures involved.

At melting points required for these refractory metals, ceramic materials can degrade and react with the melt. This introduces foreign inclusions that ruin the chemical purity of the ingot.

The Water-Cooled Copper Solution

To solve this, vacuum arc furnaces utilize a water-cooled copper crucible.

The efficient circulating water creates a "cold shell" of solidified metal between the melt and the crucible wall. This "self-crucible" effect prevents the molten alloy from ever touching the container directly, eliminating the risk of contamination.

Achieving Atomic Homogeneity

The Necessity of Uniformity

Simply melting the metals together is insufficient; the elements must be distributed evenly at the atomic level to function correctly.

Inconsistent distribution leads to weak points in the material or unpredictable mechanical properties.

The Function of Re-melting

The vacuum arc furnace facilitates this through the capability of performing multiple re-melting cycles.

By melting the alloy repeatedly, the furnace ensures that elements with different densities are thoroughly mixed. This process guarantees that the final ingot achieves superior structural uniformity.

Understanding the Trade-offs

While vacuum arc melting is the gold standard for Ti-Zr-Nb alloys, it is an energy-intensive and complex batch process.

Cycle Time: Because high homogeneity requires multiple re-melting cycles, the production time per ingot is significantly longer than single-pass melting methods.

Volume Limitations: Unlike continuous casting methods used for simpler metals, vacuum arc furnaces are typically limited to producing discrete ingots, which may constrain high-volume throughput.

Making the Right Choice for Your Goal

When configuring your melting process for Ti-Zr-Nb alloys, prioritize your parameters based on the final application requirements.

- If your primary focus is Chemical Purity: Prioritize the integrity of the vacuum system and argon purity to absolutely minimize oxygen pickup.

- If your primary focus is Microstructural Uniformity: Increase the number of re-melting cycles to ensure complete homogenization of the refractory elements.

Ultimately, the vacuum arc furnace is not just a heat source; it is a contamination control system that defines the quality of the final material.

Summary Table:

| Feature | Function in Ti-Zr-Nb Melting | Benefit |

|---|---|---|

| Vacuum/Argon Environment | Eliminates atmospheric oxygen and nitrogen | Prevents chemical degradation and oxidation |

| Water-Cooled Copper Crucible | Creates a "self-crucible" cold shell | Eliminates ceramic inclusions and maintains purity |

| Multiple Re-melting Cycles | Continuous mixing of refractory elements | Achieves superior atomic-level homogeneity |

| High-Intensity Electric Arc | Provides extreme, localized heat | Effectively melts refractory metals with high melting points |

Elevate Your Alloy Production with KINTEK

Precise control over chemical reactivity and structural uniformity is non-negotiable for high-performance Ti-Zr-Nb alloys. KINTEK provides industry-leading vacuum melting solutions designed to meet the rigorous demands of refractory metal processing.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Vacuum, CVD, Muffle, and Tube systems, all fully customizable to your specific laboratory or industrial needs. Whether you require enhanced purity or superior homogeneity, our equipment ensures your materials meet the highest standards.

Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- K. V. Sergienko, A. G. Kolmakov. Physical and Mechanical Properties of Ti-Zr-Nb Alloys for Medical Use. DOI: 10.3390/met14111311

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a vacuum environment important in a VIM furnace? Unlock Purity and Performance in Metal Melting

- What role does a Vacuum Induction Melting Furnace play in carbide-free bainitic steel? Secure High-Purity Alloy Results

- Why are vacuum casting furnaces considered vital for modern manufacturing? Unlock Purity and Performance

- What are the main advantages of vacuum melting furnaces? Achieve Ultra-Pure Metals for High-Performance Applications

- What role does a Vacuum Induction Melting (VIM) furnace play in the recycling of low alloy steel? Ensure Purity.

- How do induction melting furnaces ensure superior metal quality? Achieve Purity, Homogeneity & Control

- How does core type induction heating work? Unlock Efficient, Controlled Heat for Metals