At their core, vacuum casting furnaces are vital because they create an environment free of air and other gases during high-temperature metal processing. This seemingly simple act of removing the atmosphere fundamentally prevents oxidation and contamination, allowing for the creation of exceptionally pure, high-strength materials that are impossible to produce with conventional methods.

The critical advantage of a vacuum furnace is not just what it does, but what it removes. By eliminating atmospheric interference, it unlocks a level of material control and purity essential for the most demanding applications in modern industry.

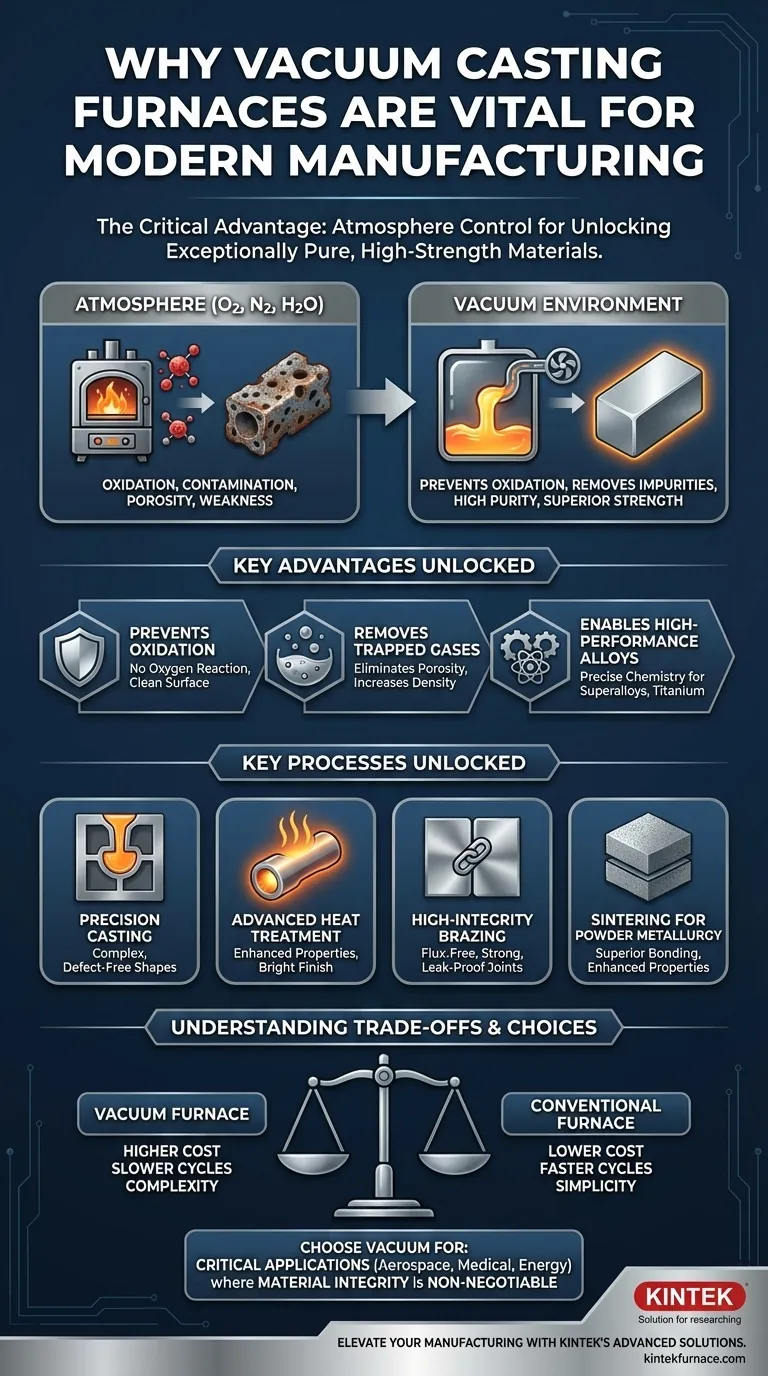

The Fundamental Advantage: Controlling the Atmosphere

Heating metal in the open air, or even in a standard furnace, introduces oxygen and other reactive gases. This causes unwanted chemical reactions that compromise the material's final quality. A vacuum furnace solves this by removing the atmosphere before applying heat.

Preventing Oxidation and Contamination

When metals are heated, they readily react with oxygen, forming oxides on the surface and within the material. This oxidation weakens the metal and can ruin its desired properties.

A vacuum environment, by definition, has virtually no oxygen, completely preventing oxidation even at extreme temperatures. This ensures the material's surface remains clean and its internal chemistry is unaltered.

Removing Trapped Gases and Impurities

The vacuum actively pulls dissolved gases, like hydrogen and nitrogen, out of the molten metal. These trapped gases are a primary cause of porosity, a critical defect that creates weak spots in the final product.

By de-gassing the material, the furnace produces parts that are denser, stronger, and more reliable under stress. This process is essential for creating void-free components for critical applications.

Enabling High-Performance Alloys

Industries like aerospace and medical implants rely on superalloys and specialized metals (like titanium) with highly specific chemical compositions.

Even trace amounts of atmospheric contamination can disrupt these precise recipes, degrading performance. Vacuum furnaces provide the inert environment required to melt, mix, and cast these sensitive alloys without compromising their integrity.

Key Processes Unlocked by Vacuum Technology

While the term "casting" is in the question, the technology enables a suite of advanced manufacturing processes. Understanding these reveals the full scope of its importance.

Precision Casting and Melting

This is the process of creating a final shape from molten metal. In a vacuum, the resulting cast part is free from gas-related defects and surface oxides, making it ideal for turbine blades, medical implants, and other high-stress components.

Advanced Heat Treatment

Heat treatment modifies the internal crystal structure of a metal to enhance its properties, such as hardness or ductility. Performing this in a vacuum ensures a clean, bright finish and prevents the degradation of the material's surface during the process.

High-Integrity Brazing and Joining

Vacuum brazing is a method for joining two pieces of metal. It produces exceptionally strong, clean, and leak-proof joints without the need for corrosive flux, as the vacuum itself acts as the cleaning agent. This is critical for assembling complex electronic and aerospace components.

Sintering for Powder Metallurgy

Sintering is the process of fusing powdered metals into a solid, dense part using heat. A vacuum ensures that no oxides form on the powder particles, leading to superior bonding and a final component with enhanced mechanical properties.

Understanding the Trade-offs

Despite their advantages, vacuum furnaces are not a universal solution. Their benefits come with clear and important considerations.

High Initial Investment and Operating Costs

Vacuum furnaces are significantly more complex and expensive than their atmospheric counterparts. The vacuum pumps, control systems, and chamber engineering represent a major capital investment.

Slower Process Cycle Times

Achieving a deep vacuum takes time. The pump-down phase adds to the overall cycle time for each batch, which can make the process slower than conventional heating methods for high-volume, low-spec production.

Increased Operational Complexity

Operating and maintaining a vacuum furnace requires specialized training. Managing vacuum levels, preventing leaks, and servicing the complex systems is more demanding than running a standard furnace.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace must be driven by the non-negotiable requirements of the final product.

- If your primary focus is maximum material purity and performance: For applications in aerospace, energy, or medical devices where failure is not an option, a vacuum furnace is essential.

- If your primary focus is creating strong, flux-free joints: For complex assemblies or components that must be perfectly clean, vacuum brazing is the superior choice.

- If your primary focus is on high-volume, cost-sensitive production: For general-purpose parts where minor surface oxidation is acceptable, a traditional atmospheric furnace is often more practical.

Ultimately, adopting vacuum furnace technology is a strategic decision to prioritize material integrity above all else.

Summary Table:

| Key Aspect | Description |

|---|---|

| Prevents Oxidation | Eliminates oxygen to avoid surface and internal degradation of metals during heating. |

| Removes Impurities | Extracts dissolved gases like hydrogen and nitrogen to reduce porosity and increase strength. |

| Enables High-Performance Alloys | Allows precise melting and casting of sensitive materials like superalloys and titanium without contamination. |

| Key Processes | Includes precision casting, advanced heat treatment, vacuum brazing, and sintering for superior results. |

| Trade-offs | Higher costs, slower cycle times, and increased operational complexity compared to conventional furnaces. |

Elevate Your Manufacturing with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical devices, or energy sectors, our vacuum furnaces ensure maximum material purity, strength, and reliability for critical applications. Don't let contamination hold you back—contact us today to discuss how we can tailor a solution for your specific needs and drive your innovations forward!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion