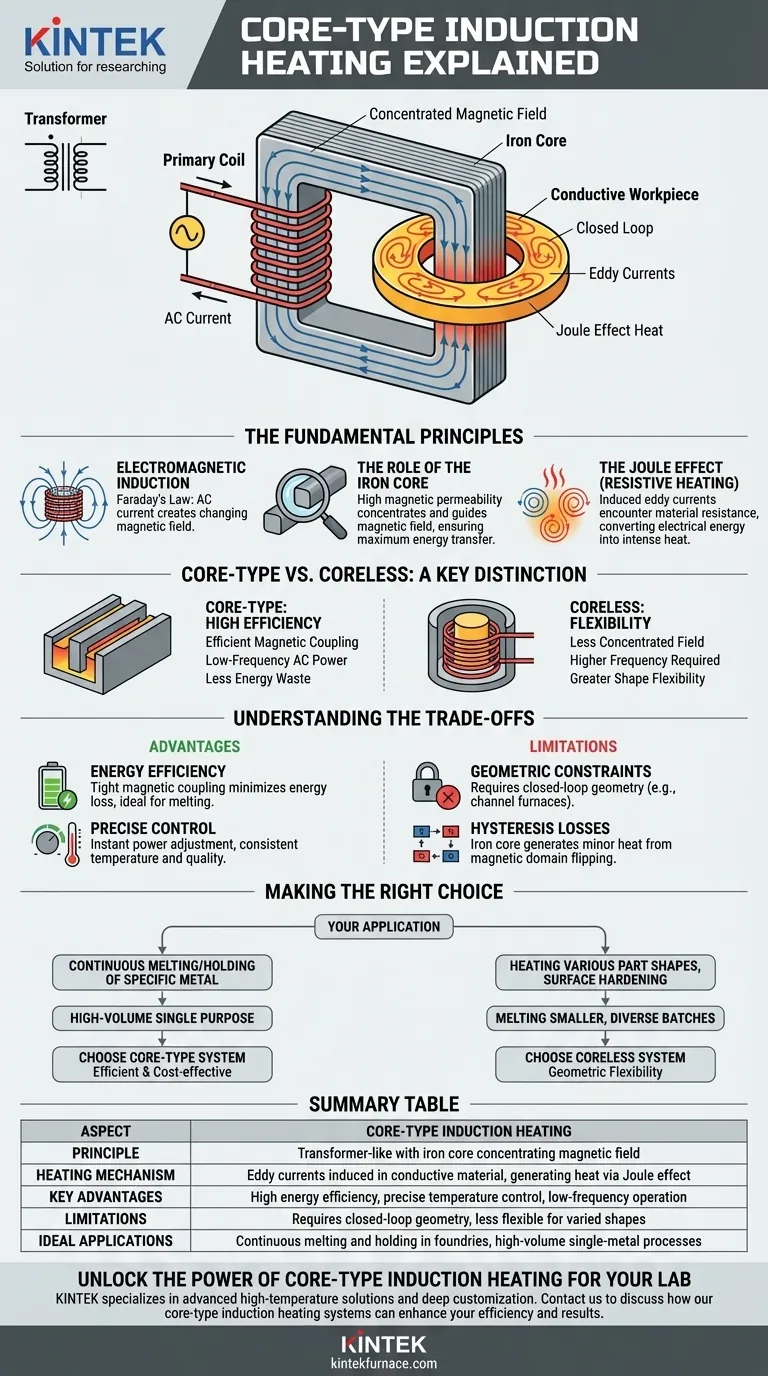

At its core, a core-type induction heater functions like a specialized transformer where the object to be heated acts as a short-circuited secondary coil. An alternating current (AC) flows through a primary coil wrapped around an iron core, generating a powerful, concentrated magnetic field within that core. This field then induces strong electrical currents (eddy currents) directly within the conductive material, and the material's inherent resistance to this current flow generates intense, controllable heat.

The central purpose of the iron core is to efficiently concentrate and guide the magnetic field. This creates a highly effective energy transfer, allowing for powerful heating at lower electrical frequencies than would otherwise be possible.

The Fundamental Principles at Play

To understand how a core-type system works, we must look at two foundational physics principles and the critical role of the core itself.

Electromagnetic Induction

This process begins with Faraday's Law of Induction. When an alternating electrical current passes through the system's primary coil, it creates a constantly changing magnetic field. This fluctuating field is the engine of the entire heating process.

The Role of the Iron Core

The iron core is the defining component. Because iron is a ferromagnetic material, it has very high magnetic permeability. It acts as a highly efficient channel, capturing and concentrating the magnetic field lines generated by the primary coil. This ensures the maximum amount of magnetic energy is coupled directly into the material being heated.

Think of it like using a lens to focus sunlight. The core takes the diffuse magnetic field and focuses it precisely where it's needed, dramatically increasing the system's efficiency.

The Joule Effect (Resistive Heating)

The concentrated, changing magnetic field from the core passes through the conductive workpiece (the "charge"). This induces powerful, swirling electrical currents within the metal, known as eddy currents.

As these eddy currents flow, they are met with the material's natural electrical resistance. This opposition converts the electrical energy directly into thermal energy, a phenomenon known as the Joule effect. This is what causes the material's temperature to rise rapidly.

Core-Type vs. Coreless: A Key Distinction

The presence or absence of the iron core is the primary difference between the two main types of induction furnaces.

Core-Type: Efficiency Through Concentration

Because the core provides such effective magnetic coupling, core-type systems can achieve powerful heating using relatively low-frequency AC power. The high efficiency of the magnetic circuit means less energy is wasted.

Coreless: Flexibility with Higher Frequencies

Coreless systems place the workpiece directly inside the coil with no intervening core. This results in a much less concentrated magnetic field (lower flux density). To compensate and generate sufficient heat, these systems must operate at a much higher frequency. While less efficient, this design offers greater flexibility for heating objects of various shapes and sizes.

Understanding the Trade-offs

Choosing core-type induction heating involves clear advantages but also specific limitations that are critical to understand.

Advantage: Energy Efficiency

The tight magnetic coupling created by the iron core makes this one of the most energy-efficient methods for melting and holding metals in specific applications. Very little magnetic energy is lost to the surrounding environment.

Advantage: Precise Control

Like all induction heating, the core-type method offers exceptionally precise and repeatable temperature control. Power can be adjusted instantly, allowing for consistent quality and metallurgical properties in the final product.

Limitation: Geometric Constraints

The primary drawback is a lack of flexibility. For the transformer principle to work, the material to be heated must form a complete, closed loop around the core. This is why core-type heaters are almost exclusively found in channel furnaces, where a continuous channel of molten metal encircles the core.

Consideration: Hysteresis Losses

While the workpiece is heated by eddy currents, the iron core itself is subject to minor heating from hysteresis losses. This is the energy required to repeatedly flip the magnetic domains within the iron as the AC field alternates. This is a factor in the equipment's design and cooling requirements.

Making the Right Choice for Your Application

Your application's specific geometry and process goals will determine whether a core-type system is the appropriate solution.

- If your primary focus is continuous melting and holding of a specific metal in a dedicated furnace: Core-type induction is extremely efficient and cost-effective for high-volume, single-purpose operations like those in foundries.

- If your primary focus is heating various part shapes, performing surface hardening, or melting smaller, diverse batches: A coreless induction system provides the necessary geometric flexibility that a core-type system cannot.

Understanding this fundamental difference in how the magnetic field is managed is the key to selecting the most effective heating technology for your industrial process.

Summary Table:

| Aspect | Core-Type Induction Heating |

|---|---|

| Principle | Transformer-like with iron core concentrating magnetic field |

| Heating Mechanism | Eddy currents induced in conductive material, generating heat via Joule effect |

| Key Advantages | High energy efficiency, precise temperature control, low-frequency operation |

| Limitations | Requires closed-loop geometry (e.g., channel furnaces), less flexible for varied shapes |

| Ideal Applications | Continuous melting and holding in foundries, high-volume single-metal processes |

Unlock the Power of Core-Type Induction Heating for Your Lab

At KINTEK, we specialize in advanced high-temperature solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, whether you're in metal processing, materials science, or industrial research.

Contact us today to discuss how our core-type induction heating systems can enhance your efficiency and results—Get in touch now!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control