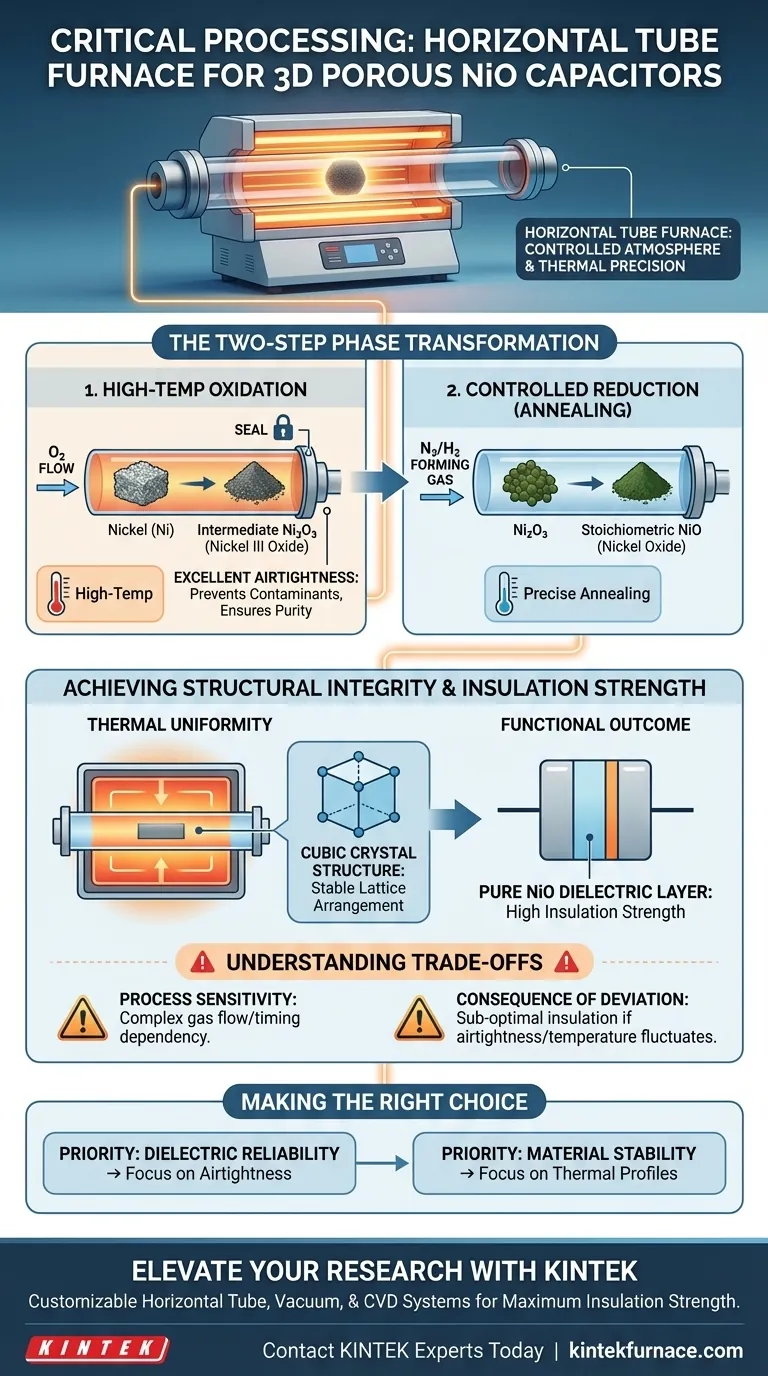

The critical processing conditions provided by a horizontal tube furnace are a strictly controlled atmosphere and precise thermal uniformity. These features enable a specific two-step phase transformation—high-temperature oxidation followed by controlled reduction—which is required to convert nickel into stoichiometric nickel oxide (NiO) with a stable cubic crystal structure.

The integrity of the dielectric layer relies on converting intermediate phases into pure, stoichiometric NiO. This requires the exceptional airtightness and thermal precision that a tube furnace provides to ensure high insulation strength.

Achieving Stoichiometry Through Atmosphere Control

The Oxidation Phase

The first critical step involves high-temperature oxidation. The furnace allows for a consistent flow of oxygen to interact with the material.

This environment converts the initial nickel component into an intermediate phase, specifically nickel (III) oxide (Ni₂O₃). This oxidation serves as the foundational step for the subsequent structural transformation.

The Reduction Phase

Following oxidation, the material must undergo an annealing process in a forming gas, such as a nitrogen/hydrogen (N₂/H₂) mix.

This step acts as a reduction phase, chemically altering the Ni₂O₃. It effectively transforms the intermediate oxide into stoichiometric NiO, which is the desired final state for the capacitor's dielectric.

The Role of Airtightness

These chemical reactions are highly sensitive to external contaminants. The excellent airtightness of the horizontal tube furnace is paramount here.

By isolating the internal environment, the furnace ensures that the atmosphere consists only of the intended process gases. This isolation guarantees the chemical purity required to achieve the correct phase structure.

Thermal Uniformity and Structural Integrity

Ensuring Cubic Crystal Structure

Temperature control is not just about reaching a specific degree; it is about maintaining temperature uniformity across the entire sample.

The tube furnace provides the stable thermal profile necessary to crystallize the NiO into a cubic crystal structure. This specific lattice arrangement is directly responsible for the material's physical stability.

Impact on Insulation Strength

The ultimate goal of this thermal processing is functional reliability. The combination of stoichiometric composition and cubic structure ensures the insulation strength of the dielectric layer.

Without the precise temperature profiles provided by the furnace, the dielectric layer may suffer from defects, compromising the capacitor's performance.

Understanding the Trade-offs

Process Sensitivity

While the horizontal tube furnace offers precision, it also demands rigorous process control. The two-step nature of the treatment (oxidation followed by reduction) creates a complex dependency on gas flow rates and switching timing.

Consequence of Deviation

If the airtightness is compromised or the temperature profile fluctuates even slightly, the material may fail to reach the stoichiometric NiO state. This results in sub-optimal insulation properties, rendering the 3D porous capacitor ineffective for high-performance applications.

Making the Right Choice for Your Goal

To maximize the performance of your 3D porous NiO capacitors, align your processing parameters with your specific engineering objectives:

- If your primary focus is Dielectric Reliability: Prioritize the airtightness of the furnace system to prevent atmospheric contamination and ensure purely stoichiometric NiO formation.

- If your primary focus is Material Stability: Focus on the precision of the temperature profiles during the annealing phase to guarantee the formation of a robust cubic crystal structure.

Precision in the furnace environment is the single most important factor in determining the final insulation quality of your device.

Summary Table:

| Process Phase | Gas Environment | Temperature Objective | Structural Outcome |

|---|---|---|---|

| Oxidation | Oxygen (O₂) Flow | High-Temp Oxidation | Formation of Ni₂O₃ intermediate |

| Reduction | Forming Gas (N₂/H₂) | Controlled Annealing | Conversion to stoichiometric NiO |

| Crystallization | Inert/Process Gas | Uniform Thermal Profile | Stable cubic crystal lattice |

| Final State | Sealed Atmosphere | High Insulation Strength | Pure NiO dielectric layer |

Elevate Your Semiconductor Research with KINTEK

Precise phase transformation in NiO capacitors demands the highest standards of atmospheric purity and thermal stability. KINTEK provides state-of-the-art Horizontal Tube, Vacuum, and CVD systems designed to meet the rigorous needs of advanced materials engineering.

Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to your specific gas flow and temperature profile requirements, ensuring your dielectric layers achieve maximum insulation strength and structural integrity.

Ready to optimize your lab's thermal processing?

Visual Guide

References

- Baichuan Zhang, Jihua Zhang. Novel 3D Capacitors: Integrating Porous Nickel-Structured and Through-Glass-Via-Fabricated Capacitors. DOI: 10.3390/nano15110819

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the function of a Quartz Tube Furnace in the dry thermal oxidation of silicon wafers? Enhance Your Oxide Quality

- What is the function of a tube furnace in catalyst annealing? Unlock L10 Ordered Structures for Peak Performance

- At what pressures can gases be introduced into the 3-Zone tube furnace? Optimize Your Thermal Process Control

- What is the function of vacuum-sealed silica tubes in FeTeSe synthesis? Ensure Purity & Precise Stoichiometry

- What role does a high-temperature tube furnace play in N-CP synthesis? Mastering Precision Carbonization

- What function does a tube furnace perform in sintering boron duplex stainless steel? Master High-Precision Results

- What types of heating elements can be used in split tube furnaces? Choose SiC or MoSi2 for Optimal Performance

- What is the primary function of a high-temperature tube furnace in solid-state chemical synthesis? | Expert Guide