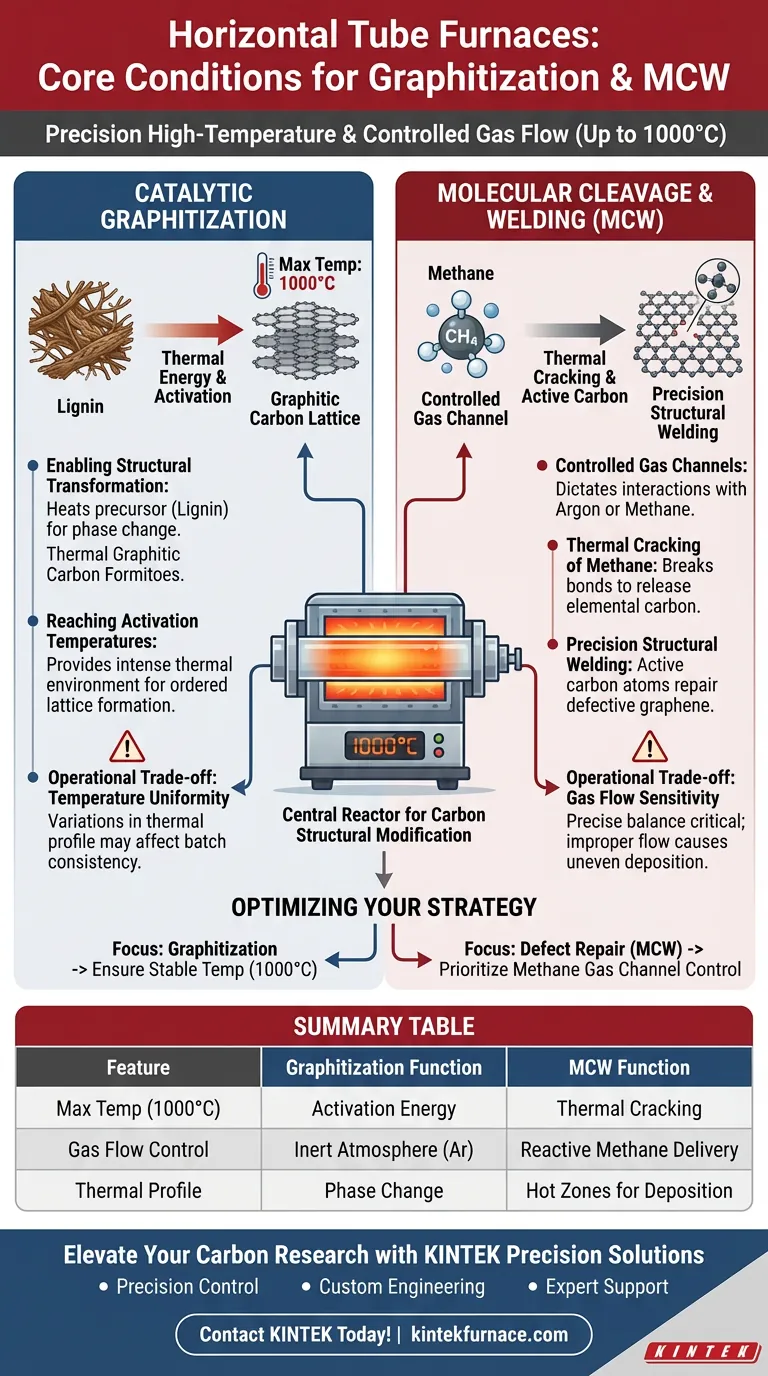

Horizontal tube furnaces provide a precise high-temperature environment reaching up to 1000°C combined with controlled gas flow channels. These systems are essential for supplying the thermal energy required to transform lignin into graphitic carbon and for maintaining the reactive atmosphere necessary to crack methane for molecular repair.

The horizontal tube furnace acts as the central reactor for carbon structural modification, simultaneously providing the heat for graphitization and the specific atmospheric control required for Molecular Cleavage and Welding (MCW).

The Critical Role of Thermal Management

Enabling Structural Transformation

The primary function of the furnace during the graphitization stage is energy supply. The system heats the precursor material, specifically lignin, to facilitate a phase change.

Reaching Activation Temperatures

To successfully achieve a graphitic carbon structure, the furnace must reach temperatures up to 1000°C. This intense thermal environment provides the activation energy necessary to rearrange the atomic structure of the lignin into an ordered lattice.

Facilitating Molecular Cleavage and Welding (MCW)

Controlled Gas Channels

Beyond simple heating, the furnace provides specific flow channels for processing gases. This creates a controlled environment using gases such as Argon (inert) or Methane (reactive) to dictate chemical interactions.

Thermal Cracking of Methane

During the MCW stage, the furnace maintains the high temperatures required to thermally crack methane molecules. This process breaks the hydrocarbon bonds to release elemental carbon.

Precision Structural Welding

The cracking process produces active carbon atoms within the hot zone. These atoms "weld" onto defective graphite layers, allowing for the precise modification and repair of multilayer graphene structures.

Understanding Operational Trade-offs

Temperature Uniformity

While horizontal tube furnaces excel at reaching high temperatures, maintaining perfect uniformity along the length of the tube can be difficult. Variations in the thermal profile may affect the consistency of the graphitization across the sample batch.

Gas Flow Sensitivity

The success of the MCW process relies heavily on the precise balance of gas flow and temperature. If the flow of Methane is not perfectly calibrated with the cracking temperature, it can lead to uneven carbon deposition or incomplete structural welding.

Optimizing Your Processing Strategy

To effectively utilize a horizontal tube furnace for carbon processing, align your parameters with your specific end goal:

- If your primary focus is Graphitization: Ensure the furnace can sustain stable temperatures up to 1000°C to maximize the conversion of lignin into a graphitic structure.

- If your primary focus is Defect Repair (MCW): Prioritize precise control over the methane gas channels to generate the active carbon atoms needed for effective molecular welding.

Mastering the balance between high-thermal energy and controlled atmospheric conditions is the key to engineering high-quality graphitic structures.

Summary Table:

| Feature | Function in Graphitization | Function in MCW (Molecular Cleavage) |

|---|---|---|

| Max Temp (1000°C) | Supplies activation energy for lignin-to-carbon transformation. | Provides thermal energy to crack methane molecules. |

| Gas Flow Control | Maintains inert Argon atmosphere for structural stability. | Delivers reactive methane for precision atomic welding. |

| Thermal Profile | Facilitates phase change to ordered graphitic lattice. | Creates hot zones for active carbon deposition on defects. |

Elevate Your Carbon Research with KINTEK Precision

Are you looking to master complex processes like catalytic graphitization or molecular cleavage? KINTEK provides state-of-the-art thermal solutions tailored for high-stakes laboratory research. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique processing temperatures and atmospheric requirements.

Why choose KINTEK?

- Precision Control: Achieve the exact thermal profiles needed for structural welding and defect repair.

- Custom Engineering: Our furnaces are designed to handle specific gas flow channels for Methane, Argon, and more.

- Expert Support: Benefit from our deep understanding of high-temp lab applications to optimize your batch consistency.

Contact KINTEK Today to Customize Your High-Temperature Furnace!

Visual Guide

References

- Qiangu Yan, Zhiyong Cai. Tuning thermal and graphitization behaviors of lignin <i>via</i> complexation with transition metal ions for the synthesis of multilayer graphene-based materials. DOI: 10.1039/d3ra05881f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What environmental conditions does a high-temperature Tube furnace provide for AlN nanofibers? | KINTEK

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision

- What is the temperature of a tube furnace? Selecting the Right High-Temp Solution for Your Lab

- What role does a Drop Tube Furnace (DTF) play? Expert Insights into Industrial Combustion Simulation

- What role does a vacuum tube furnace play in Ag2Se post-treatment? Optimize Flexible Thermoelectric Efficiency

- What are the advantages of using a laboratory tube furnace for BCZT ceramics? Boost Piezoelectric d33 by up to 41%

- What specific research applications demonstrate the capabilities of lab tubular furnaces? Unlock Precise Thermal Processing

- What role does a laboratory tube furnace play in the carbonization process of porous carbon particles? Expert Insights