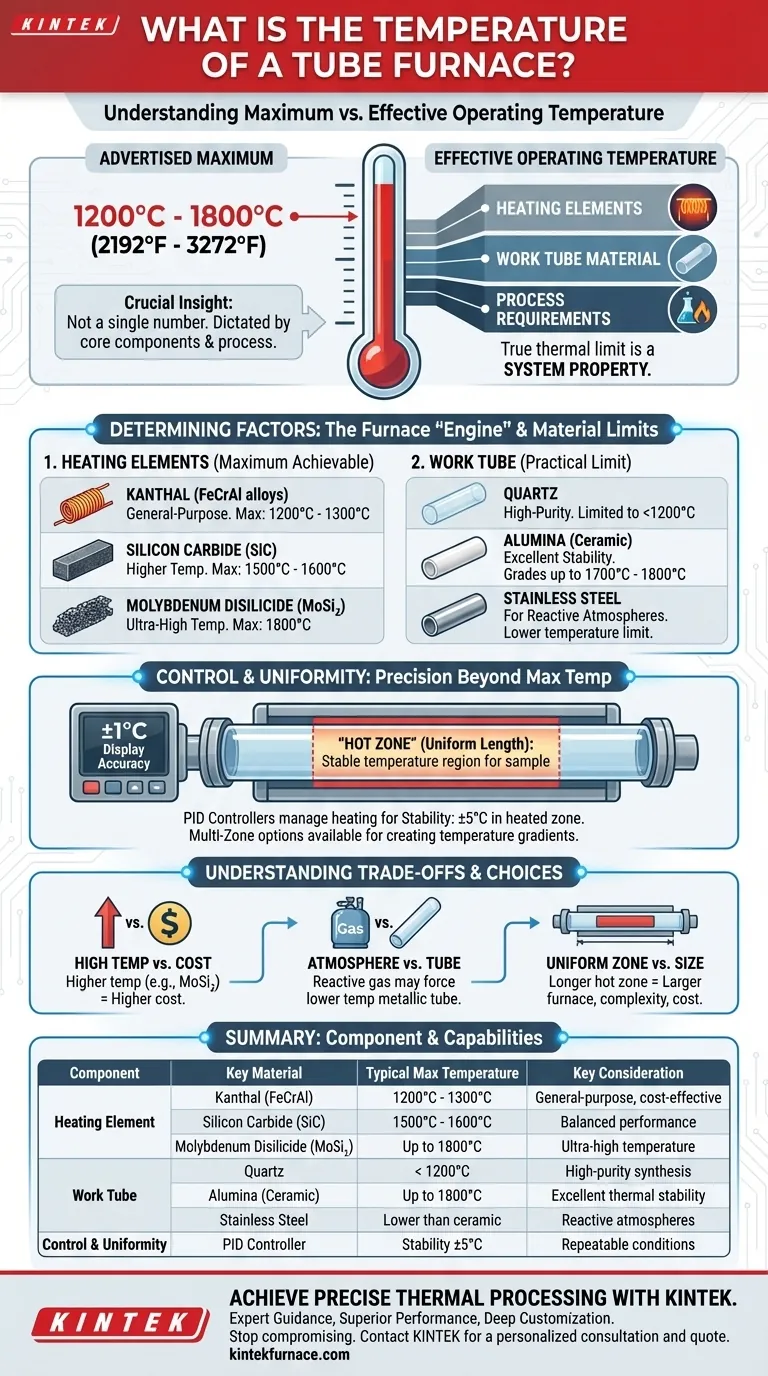

A standard laboratory tube furnace can operate at maximum temperatures ranging from 1200°C to 1800°C (2192°F to 3272°F). The specific temperature capability of any given model is not a single number but is dictated by its core components, most notably the type of heating element and the material of the work tube used.

The crucial insight is that the maximum advertised temperature and the effective operating temperature are two different things. Your true thermal limit is determined by a system of interdependent factors, including the heating elements, the work tube's material properties, and the required temperature uniformity for your specific process.

What Determines a Furnace's Maximum Temperature?

The peak temperature rating is a direct result of the materials used in the furnace's construction. Understanding these components is key to selecting the right instrument for your needs.

The Role of Heating Elements

The furnace's "engine" is its set of heating elements. The material used for these elements directly defines the upper limit of the achievable temperature.

- Kanthal (FeCrAl alloys): These are common in general-purpose furnaces and typically reach maximum temperatures of 1200°C to 1300°C.

- Silicon Carbide (SiC): For higher temperature applications, SiC elements are used, enabling furnaces to reliably operate up to 1500°C or 1600°C.

- Molybdenum Disilicide (MoSi2): These elements are reserved for very high-temperature applications, allowing furnaces to achieve their maximum rating of 1800°C.

The Limitation of the Work Tube

The sample is heated inside a work tube, which must be able to withstand the target temperature and be chemically compatible with your sample and atmosphere. The tube's material often imposes a lower practical temperature limit than the heating elements can produce.

- Quartz: Ideal for high-purity applications, but typically limited to use below 1200°C.

- Alumina (Ceramic): Offers excellent thermal stability and chemical resistance, with grades available for use up to 1700°C or 1800°C.

- Stainless Steel: Provides durability and is necessary for certain reducing or reactive atmospheres, but generally has a much lower temperature limit than ceramic tubes.

Beyond Maximum Temperature: Control and Uniformity

Simply reaching a high temperature is not enough for most scientific or industrial processes. The quality of the heat treatment depends on the precision of control and the uniformity of the temperature profile.

Achieving Temperature Precision

Modern tube furnaces use advanced control systems, such as PID (Proportional-Integral-Derivative) controllers, to manage heating. These systems provide excellent stability.

A high-quality furnace can achieve a temperature display accuracy of ±1°C and maintain temperature stability within the heated zone of ±5°C, ensuring repeatable and reliable conditions.

Understanding the "Hot Zone"

The setpoint temperature is not consistent along the entire length of the tube. The "hot zone," or uniform length, is the central region of the furnace where the temperature is stable and consistent with the setpoint.

The length of this uniform zone is a critical specification for any experiment, as your sample must fit entirely within this region to ensure it is heated evenly.

Multi-Zone Control for Gradients

Some advanced furnaces feature multiple heating zones along the length of the tube. Each zone can be controlled independently, allowing a user to create a precise temperature gradient. This is essential for processes like chemical vapor transport or specialized crystal growth.

Understanding the Trade-offs

Choosing a tube furnace involves balancing performance requirements with practical constraints, primarily cost and material compatibility.

High Temperature vs. Cost

There is a direct and steep correlation between maximum temperature and price. A furnace capable of 1800°C requires expensive MoSi2 elements and high-grade insulation, making it significantly more costly than a 1200°C model using Kanthal elements.

Atmosphere vs. Tube Material

Your choice of process atmosphere dictates the tube material, which in turn can limit your operating temperature. If your process requires a reactive gas that would damage a ceramic tube, you may be forced to use a metallic tube, thereby accepting a lower maximum temperature.

Uniform Zone vs. Furnace Size

A longer, more uniform hot zone is highly desirable for processing larger samples or improving batch consistency. However, achieving this requires a physically larger furnace, more sophisticated heating element design, and often multiple control zones, all of which increase complexity and cost.

Making the Right Choice for Your Goal

To select the correct furnace, align its temperature capabilities with the specific demands of your application.

- If your primary focus is high-purity synthesis below 1200°C: A furnace compatible with a quartz work tube is the ideal choice to prevent contamination.

- If your primary focus is general-purpose lab work up to 1500°C: A furnace with SiC elements and an alumina work tube offers the best balance of performance and cost.

- If your primary focus is ultra-high temperature processing (above 1500°C): You must invest in a furnace with MoSi2 elements and a high-purity alumina tube.

- If your primary focus is working with reactive atmospheres: Prioritize selecting the correct tube material (e.g., stainless steel) first, and then accept the maximum temperature that the tube allows.

By understanding that a furnace's temperature is a system property, not just a single number, you can make a more informed decision and ensure successful outcomes for your work.

Summary Table:

| Component | Key Material | Typical Max Temperature | Key Consideration |

|---|---|---|---|

| Heating Element | Kanthal (FeCrAl) | 1200°C - 1300°C | General-purpose, cost-effective |

| Silicon Carbide (SiC) | 1500°C - 1600°C | Balanced performance for most labs | |

| Molybdenum Disilicide (MoSi₂) | Up to 1800°C | Ultra-high temperature processing | |

| Work Tube | Quartz | < 1200°C | High-purity synthesis, prevents contamination |

| Alumina (Ceramic) | Up to 1800°C | Excellent thermal stability & chemical resistance | |

| Stainless Steel | Lower than ceramic | Required for specific reactive atmospheres | |

| Control & Uniformity | PID Controller | Stability ±5°C | Ensures repeatable and reliable conditions |

Achieve Precise Thermal Processing with KINTEK

Selecting the right tube furnace is critical for your research or production success. The interplay between maximum temperature, material compatibility, and temperature uniformity directly impacts your results.

KINTEK's advanced high-temperature furnace solutions are engineered to meet your exact requirements:

- Expert Guidance: Leverage our deep application knowledge to select the optimal combination of heating elements (Kanthal, SiC, MoSi₂) and work tube materials (Quartz, Alumina, Stainless Steel) for your specific process and atmosphere.

- Superior Performance: Our Tube Furnaces, part of a comprehensive product line including Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are built for exceptional temperature control (±1°C display accuracy) and uniform hot zones.

- Deep Customization: We don't just sell standard models. Our strong in-house R&D and manufacturing capabilities allow us to tailor furnace specifications—like hot zone length and multi-zone control—to your unique experimental needs.

Stop compromising on your thermal processes. Let our experts help you configure a system that delivers the precision, reliability, and performance your work demands.

Contact KINTEK today for a personalized consultation and quote.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents