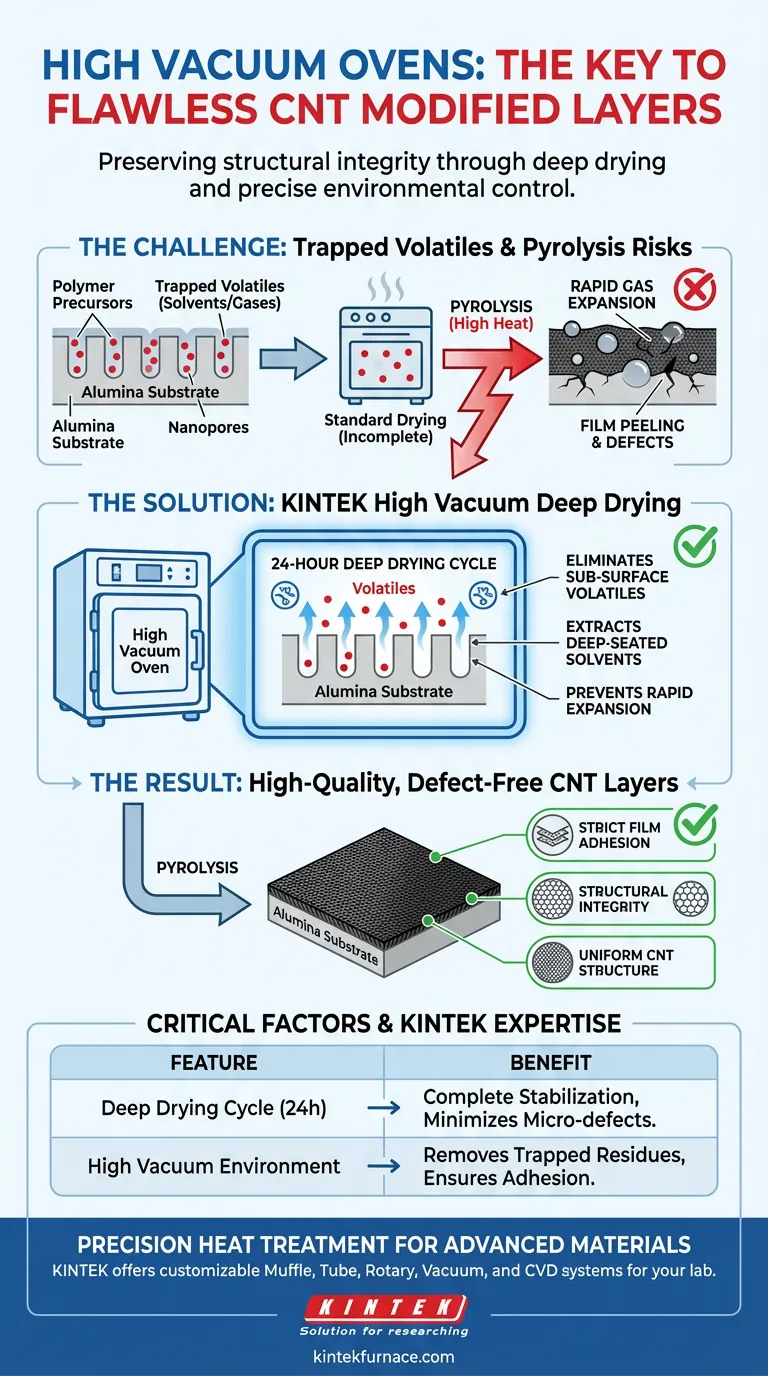

The primary contribution of a high vacuum oven is the preservation of structural integrity during the Carbon Nanotube (CNT) fabrication process. Specifically, it subjects alumina substrates impregnated with polymer precursors to a 24-hour deep drying cycle. This critical step eliminates volatile elements that would otherwise destroy the coating during subsequent processing.

By extracting deep-seated solvents and gases from nanopores, the vacuum oven prevents rapid gas expansion during pyrolysis. This ensures the CNT film remains strictly adhered to the substrate and free of structural defects.

The Mechanics of Defect Prevention

Eliminating Sub-Surface Volatiles

Standard drying methods often fail to reach contaminants trapped deep within the material structure.

A high vacuum oven is required to thoroughly remove solvent residues and adsorbed gases from the nanopores of the alumina substrate. This deep cleaning is essential because these microscopic pockets can trap significant amounts of volatile material.

Managing the Pyrolysis Transition

The fabrication process involves a transition to high-temperature pyrolysis to carbonize the precursors.

If solvents remain within the pores during this heating stage, they will vaporize instantly. The high vacuum oven acts as a preventative measure, ensuring the substrate is completely dry before it faces extreme heat.

Ensuring Adhesion and Integrity

Preventing Film Peeling

The most immediate risk of skipped vacuum drying is adhesion failure.

When trapped liquids turn to gas rapidly during pyrolysis, the resulting pressure forces the developing film away from the substrate. By removing these elements beforehand, the oven ensures the carbon nanotube film does not peel off.

Avoiding Structural Defects

Beyond total delamination, trapped gases can cause microscopic damage.

Rapid gas expansion can create cracks, bubbles, or uneven density within the CNT layer. The 24-hour vacuum cycle stabilizes the polymer precursor, allowing for the formation of a uniform, high-quality carbon structure.

Understanding the Trade-offs

The Necessity of Cycle Time

The 24-hour duration specified in the process is a significant time investment.

Attempts to shorten this drying period to increase throughput often result in incomplete solvent removal. This leads to inconsistent batch quality and an increased rejection rate due to peeling.

Equipment Dependencies

Not all drying equipment is sufficient for this application.

A standard convection oven cannot generate the negative pressure required to "pull" residues out of nanopores. Reliance on high vacuum capability is non-negotiable for achieving the defect-free baseline required for high-performance CNT layers.

Making the Right Choice for Your Goal

To ensure consistent quality in your CNT modified layers, prioritize the drying parameters as heavily as the pyrolysis steps.

- If your primary focus is Film Adhesion: Ensure the vacuum cycle runs the full 24 hours to guarantee the complete removal of gases that cause peeling.

- If your primary focus is Structural Uniformity: distinct focus on the vacuum level is required to clear nanopores, preventing micro-defects caused by expansion.

The high vacuum oven is not merely a drying tool; it is the gatekeeper that stabilizes your material against the destructive forces of high-temperature pyrolysis.

Summary Table:

| Feature | Impact on CNT Quality | Benefit |

|---|---|---|

| Deep Drying Cycle | Eliminates volatile elements from nanopores | Prevents rapid gas expansion during pyrolysis |

| High Vacuum Environment | Removes trapped solvent residues and gases | Ensures strict film adhesion to the substrate |

| 24-Hour Processing | Guarantees complete stabilization of precursors | Minimizes micro-defects like cracks and bubbles |

| Sub-surface Cleaning | Reaches contaminants standard ovens cannot | Prevents film delamination and peeling |

Precision Heat Treatment for Advanced Materials

Don't let structural defects compromise your Carbon Nanotube research. At KINTEK, we understand that high-performance CNT layers require uncompromising environmental control.

Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique lab specifications. Whether you are scaling up production or refining delicate material structures, our high-temp furnaces provide the stability and vacuum precision you need.

Ready to elevate your material quality? Contact KINTEK today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Sheida Morsali, Mahmoud Moharrami. Synthesis and characterization of modified alumina membrane with carbon nano-tubes for separation of ethanol from water using sweeping gas membrane distillation. DOI: 10.1039/d5ra01731a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the main features and advantages of a vacuum heat treatment furnace? Achieve Superior Material Quality & Efficiency

- Why must Silicon Carbide (SiC) slurry be processed in a vacuum drying oven? Ensure Purity and Prevent Agglomeration

- What are the advantages of using a vacuum brazing furnace? Achieve Clean, Strong, and Flux-Free Joints

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What are the key properties of vacuum brazed connections? Achieve Strong, Clean, and Hermetic Joints

- How do continuous vacuum furnaces enhance production efficiency in large-scale metal processing? Boost Throughput and Quality

- Why does the simulation of magnesium alloy distillation require high precision? Master Vacuum for Purity

- What are the advantages of using multi-stage programmed heating for copper-iron sintering? Enhance Material Integrity