The primary advantages of a vacuum brazing furnace are its ability to create exceptionally clean, strong, and flux-free joints by preventing oxidation in a controlled atmosphere. This process offers superior temperature uniformity, minimizes material stress, and allows for the joining of dissimilar and complex materials, making it a highly precise and efficient manufacturing method.

A vacuum brazing furnace is not just a tool for joining parts; it's a controlled environment engineered to protect the integrity of your materials. Its core advantage lies in removing atmospheric contaminants, which allows for metallurgical bonds of the highest possible quality and purity.

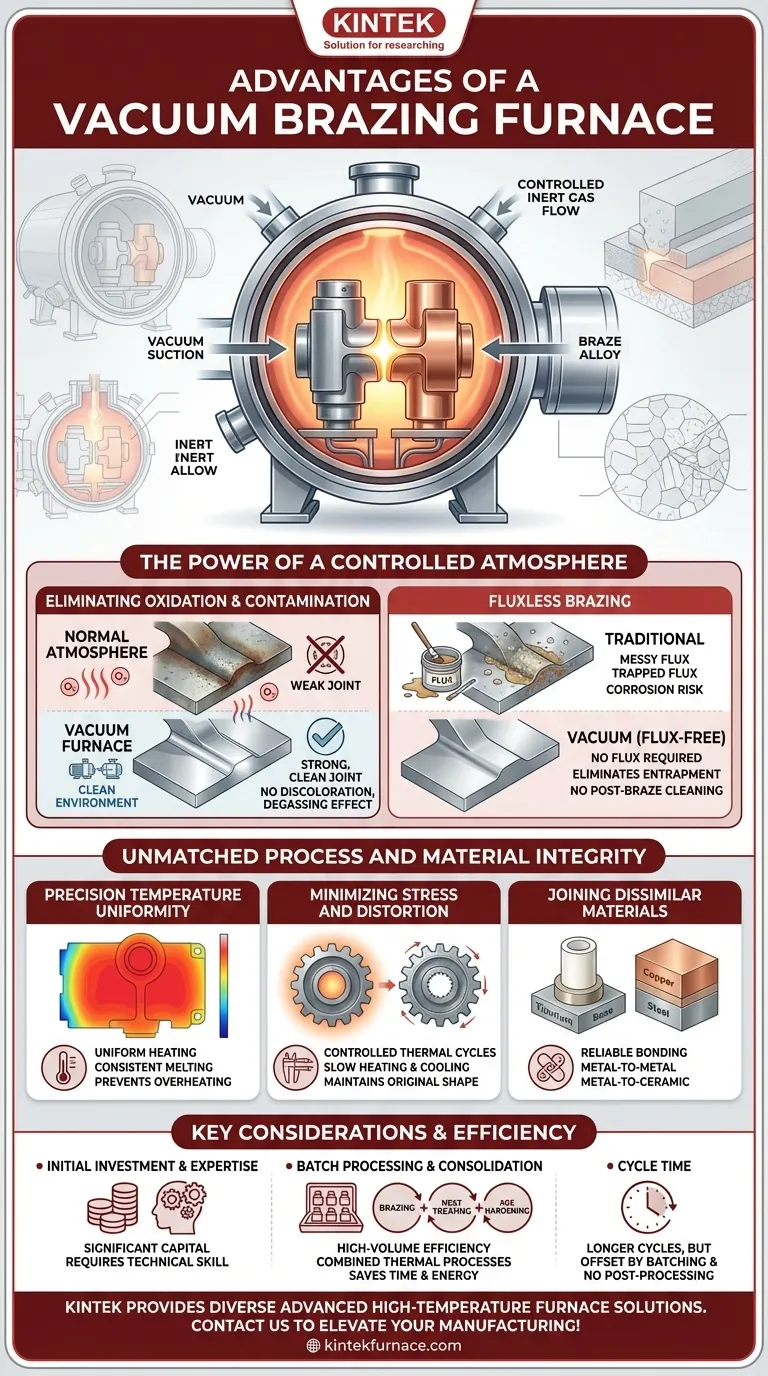

The Power of a Controlled Atmosphere

The defining feature of a vacuum furnace is the environment it creates. By removing air and other gases, it fundamentally changes the conditions under which materials are joined, leading to superior outcomes.

Eliminating Oxidation and Contamination

In a normal atmosphere, heating metals causes them to oxidize, creating a layer that weakens the brazed joint. A vacuum furnace removes the oxygen, preventing this from happening.

This results in bright, shiny, and clean joints straight out of the furnace, with no discoloration. The vacuum also has a degassing effect, pulling trapped gases out of the base materials, which further enhances the final hardness and quality of the joint.

The Advantage of Fluxless Brazing

Traditional brazing often requires a chemical flux to clean the surfaces and prevent oxidation. This flux can become trapped in the joint, creating a potential point of failure or corrosion.

Because a vacuum furnace environment is inherently clean, flux is not required. This completely eliminates the risk of flux entrapment and the need for costly and time-consuming post-braze cleaning operations.

Unmatched Process and Material Integrity

Beyond creating a clean environment, a vacuum furnace provides an unparalleled level of control over the entire thermal process, safeguarding the components being joined.

Precision Temperature Uniformity

The furnace ensures that heat is applied evenly across the entire assembly. This uniform temperature is critical when joining large parts or materials with different thermal expansion rates.

Precise control prevents localized overheating and ensures the braze alloy melts and flows consistently, creating a complete and reliable bond throughout the joint.

Minimizing Stress and Distortion

Parts are subjected to very specific and often slow heating and cooling rates. This controlled thermal cycle minimizes residual stress and distortion in the final assembly.

Maintaining the material's original shape and structural integrity is a significant advantage, especially for high-precision components used in aerospace or medical applications. Some furnaces also feature rapid cooling (quenching) options with inert gas for specific metallurgical requirements.

Joining Dissimilar and Complex Materials

The highly controlled nature of vacuum brazing makes it one of the few methods capable of reliably joining dissimilar materials.

This includes bonding different metals to each other (like copper to steel) or even joining metals to non-metals like ceramics, which is essential for advanced electronic and structural components.

Understanding the Key Considerations

While the benefits are significant, a vacuum brazing furnace is a specialized piece of equipment. Understanding its operational context is crucial for making an objective decision.

Initial Investment and Expertise

Vacuum furnaces represent a significant capital investment compared to other brazing methods like torch or induction brazing.

Furthermore, developing an optimal thermal cycle and operating the equipment requires a higher level of technical expertise to manage vacuum levels, temperatures, and ramp rates effectively.

Cycle Time Considerations

The slow, controlled heating and cooling cycles that reduce stress can also result in longer overall process times compared to faster, localized heating methods.

However, this is often offset by the ability to process large batches of parts simultaneously and by eliminating post-processing steps like cleaning. For high-volume production, this batch processing can be extremely efficient.

Process Consolidation

A key efficiency gain comes from the ability to perform multiple thermal processes in one go. Operations like brazing, heat treating, and age hardening can often be combined into a single furnace cycle.

This consolidation saves significant time, energy, and material handling, streamlining the entire manufacturing workflow.

Making the Right Choice for Your Application

Selecting the right joining technology depends entirely on your project's specific requirements for quality, materials, and production scale.

- If your primary focus is ultimate joint quality and purity: Vacuum brazing is the definitive choice for creating flux-free, strong, and clean joints for critical applications like aerospace, medical, or high-vacuum systems.

- If your primary focus is joining complex or dissimilar materials: The precise thermal control and inert environment make vacuum brazing ideal for assemblies involving ceramics, titanium, stainless steels, and other advanced alloys.

- If your primary focus is high-volume, repeatable production: The ability to run large batches, consolidate heat-treating steps, and eliminate post-braze cleaning makes this a highly cost-effective and efficient process at scale.

By understanding these principles, you can confidently determine if the precision and quality of vacuum brazing align with your engineering and manufacturing goals.

Summary Table:

| Advantage | Description |

|---|---|

| Clean, Flux-Free Joints | Prevents oxidation and contamination, eliminating the need for flux and post-cleaning. |

| Superior Temperature Uniformity | Ensures even heating for consistent bonding and reduced stress. |

| Joining Dissimilar Materials | Allows reliable bonding of different metals and non-metals like ceramics. |

| Minimized Stress and Distortion | Controlled thermal cycles reduce residual stress and maintain part integrity. |

| Process Consolidation | Combines brazing, heat treating, and age hardening in one cycle for efficiency. |

Ready to elevate your manufacturing with precision vacuum brazing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our vacuum brazing furnaces can deliver clean, strong joints and improve your production efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes