At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a foundational process for creating high-performance thin films across numerous advanced industries. It is most commonly used for depositing insulating and protective layers in the fabrication of semiconductors, creating efficiency-boosting coatings for solar cells and LEDs, and applying protective barriers on materials ranging from medical implants to food packaging.

The defining advantage of PECVD is its ability to use an energy-rich plasma to deposit high-quality films at significantly lower temperatures than traditional methods. This unlocks the ability to coat temperature-sensitive materials that would otherwise be damaged or destroyed by conventional high-heat processes.

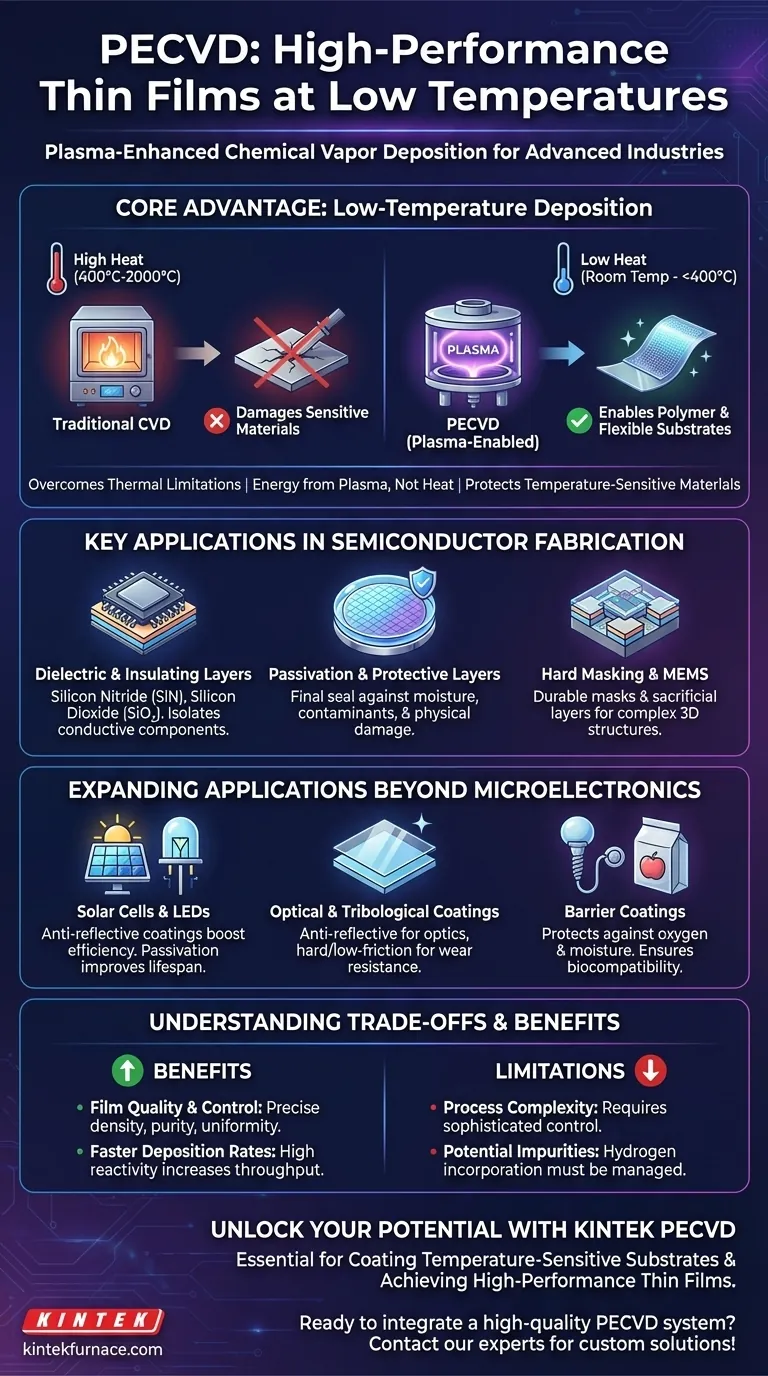

The Core Advantage: Low-Temperature Deposition

The primary reason PECVD is so widely adopted is its unique solution to the problem of heat. It fundamentally changes the energy requirements for film deposition.

Overcoming Thermal Limitations

Traditional Chemical Vapor Deposition (CVD) relies on very high temperatures, often between 400°C and 2000°C, to provide the energy needed for chemical reactions to occur on a substrate's surface.

This extreme heat makes conventional CVD incompatible with many materials, including polymers, flexible electronics, and certain complex semiconductor devices with pre-existing layers.

The Role of Plasma

PECVD circumvents this limitation by introducing energy in a different form: a plasma.

By applying an electric field to a gas, PECVD creates a plasma—an ionized state of matter containing highly reactive species. This plasma provides the activation energy for the chemical reactions, allowing for the deposition of a dense, high-quality film without requiring intense heat.

Enabling New Substrates

This low-temperature capability, sometimes operating down to room temperature, means PECVD can be used on a vast range of temperature-sensitive substrates. This has been a critical enabler for innovations in printable electronics, medical devices, and advanced optics.

Key Applications in Semiconductor Fabrication

PECVD is an indispensable workhorse in the semiconductor industry, essential for building the microscopic structures of integrated circuits and other micro-devices.

Dielectric and Insulating Layers

The most common application is depositing dielectric films, such as silicon nitride (SiN) and silicon dioxide (SiO₂). These films act as electrical insulators, isolating the millions of conductive components from each other on a single chip.

Passivation and Protective Layers

PECVD is used to apply a final protective layer, or passivation layer, to finished silicon wafers. This film seals the device, shielding it from moisture, contaminants, and physical damage that could cause it to fail.

Hard Masking and MEMS

In microelectromechanical systems (MEMS) and complex circuit patterning, PECVD films serve as durable hard masks or sacrificial layers. These temporary structures guide the etching process or help build up complex 3D geometries before being removed.

Expanding Applications Beyond Microelectronics

The versatility of PECVD has led to its adoption in a wide variety of other high-technology fields.

Solar Cells and LEDs

In photovoltaics, PECVD is used to deposit anti-reflective coatings that increase the amount of light absorbed by the solar cell. It also provides crucial passivation layers that improve the cell's overall electrical efficiency and lifespan. Similar principles apply to manufacturing high-brightness LEDs.

Optical and Tribological Coatings

PECVD is used to apply specialized coatings on glass and other surfaces. This includes creating anti-reflective layers for sunglasses and precision optical instruments or depositing extremely hard, low-friction films for components that require high wear resistance.

Barrier Coatings

The dense, uniform films created by PECVD form excellent barriers. This is used to protect flexible polymer substrates in electronics from oxygen and moisture, and even to apply an inert coating to the inside of food packaging like potato chip bags to preserve freshness. It is also used to coat medical implants to ensure biocompatibility.

Understanding the Trade-offs and Benefits

While powerful, choosing PECVD involves understanding its specific advantages and potential challenges compared to other methods.

Benefit: Film Quality and Control

PECVD allows for precise control over film properties like density, purity, and uniformity. The plasma-driven reactions can produce high-quality, conformal coatings that evenly cover even complex surface topographies.

Benefit: Faster Deposition Rates

The highly reactive nature of the plasma often leads to faster reaction kinetics and therefore higher deposition rates compared to some other low-temperature deposition techniques, improving manufacturing throughput.

Limitation: Process Complexity

A PECVD system is more complex than a simple thermal CVD reactor. Managing the plasma, gas flow, pressure, and RF power requires sophisticated control to ensure consistent and repeatable results.

Limitation: Potential Impurities

Because the process uses precursor gases that often contain hydrogen (e.g., silane), it is possible for hydrogen atoms to be incorporated into the deposited film. While this can sometimes be beneficial, it can also be an undesirable impurity that must be carefully managed.

Making the Right Choice for Your Goal

Selecting PECVD depends entirely on your material constraints and performance requirements.

- If your primary focus is fabricating integrated circuits or MEMS: PECVD is the industry standard for depositing high-quality dielectric, passivation, and structural layers without damaging thermally sensitive device architectures.

- If your primary focus is coating temperature-sensitive materials like polymers: PECVD is often the only viable choice, as its low-temperature process avoids substrate damage while still producing a dense, protective film.

- If your primary focus is enhancing optical or energy device performance: Use PECVD to engineer anti-reflective and passivation layers that directly boost the efficiency and durability of solar cells, LEDs, and optical components.

Ultimately, PECVD's ability to decouple the deposition process from high heat makes it one of the most versatile and essential tools in modern materials engineering.

Summary Table:

| Key Application Area | Primary Use of PECVD | Key Materials/Examples |

|---|---|---|

| Semiconductor Fabrication | Depositing dielectric insulating layers and protective passivation films. | Silicon Nitride (SiN), Silicon Dioxide (SiO₂) |

| Solar Cells & LEDs | Applying anti-reflective coatings and passivation layers to boost efficiency. | Photovoltaics, High-Brightness LEDs |

| Barrier & Protective Coatings | Creating dense, uniform barriers against moisture and oxygen on sensitive materials. | Medical Implants, Food Packaging, Flexible Electronics |

| Optical & Tribological Coatings | Depositing hard, wear-resistant or anti-reflective films on surfaces. | Precision Optics, Sunglasses, Mechanical Components |

Unlock the Potential of PECVD for Your Advanced Applications

PECVD's unique low-temperature capability is essential for coating temperature-sensitive substrates and achieving high-performance thin films. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced PECVD systems tailored to your specific needs.

Whether you are developing next-generation semiconductors, enhancing solar cell efficiency, or creating protective barriers for medical devices, our deep customization capabilities ensure your PECVD solution is precisely engineered for your unique experimental and production requirements.

Ready to integrate a high-quality, reliable PECVD system into your lab or production line? Contact our experts today to discuss how we can help you achieve superior thin film results.

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the disadvantages of PECVD? Navigating Process Complexity and Film Trade-offs

- What industries commonly use PECVD? Key Applications in Semiconductors, Solar, and More

- What specific thin films are commonly deposited using PECVD in integrated circuits? Essential Dielectrics for ICs

- What is the function of pulsed DC bias control during ion etching? Master DLC Coating Adhesion & Surface Activation

- What is Plasma-enhanced chemical vapor deposition (PECVD) and its applications? Unlock Low-Temperature Thin-Film Coating

- What are the limitations of PECVD compared to CVD? Key Trade-offs in Film Quality and Performance

- Why is PECVD suitable for large-scale manufacturing? Unlock High-Yield, Low-Temp Film Deposition

- What are some methods to create high-density discharges in PECVD? Boost Deposition Rates and Film Quality