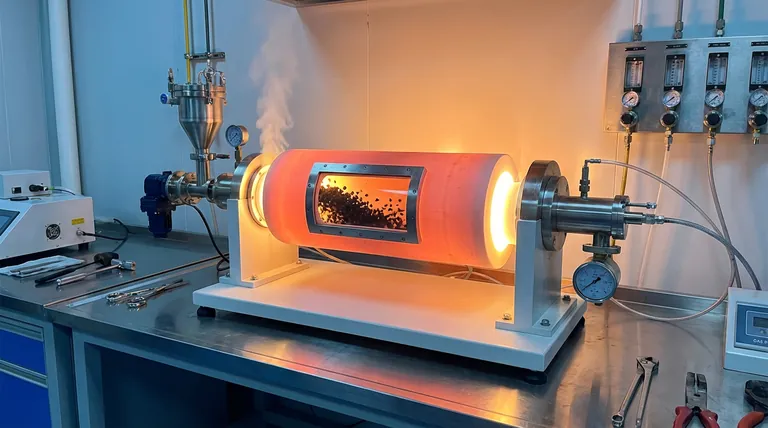

The decisive technical advantage of a rotary tube furnace lies in its ability to create a dynamic reaction environment through continuous tumbling. Unlike a static furnace where the material bed remains stationary, a rotary furnace actively stirs the hydrochar (e.g., at 7 rpm), ensuring that every particle receives uniform exposure to heat and activating gases.

The Core Insight: Static furnaces often suffer from "dead zones" within the material bed where gas cannot penetrate, leading to inconsistent product quality. By contrast, the rotary motion of a tube furnace maximizes gas-solid contact and thermal uniformity, which is a prerequisite for developing high specific surface areas (up to 200 m²/g) and ensuring a homogeneous final product.

The Mechanism of Dynamic Activation

Eliminating the "Packed Bed" Problem

In a static configuration, hydrochar sits in a dense pile. The outer layer reacts first, while the inner core may remain shielded from the activating agent.

A rotary furnace solves this by rotating the reaction tube, which causes the hydrochar to tumble continuously. This motion breaks up the material bed, ensuring that particles are constantly circulated from the interior of the bed to the surface.

Superior Gas-Solid Contact

Physical activation requires the hydrochar to interact physically with a carrier gas or agent, such as steam or CO2.

The tumbling action maximizes the surface area exposed to the atmosphere at any given moment. This improves gas diffusion into the pore structure and ensures that the activating agent reacts evenly with the carbon structure, rather than just stripping the outer layers.

Efficiency in Gas Consumption

Because the material is thoroughly mixed with the atmosphere, the reaction kinetics are more efficient.

Supplementary data indicates that this improved contact reduces the overall gas consumption required to achieve the same level of activation compared to a static process.

Thermal Uniformity and Product Consistency

Preventing Localized Overheating

A major risk in static heat treatment is the development of temperature gradients—hot spots on the outside and cold spots in the center.

The continuous stirring action distributes heat evenly throughout the batch. As heat transfers from the tube wall to the material bed, the rotation ensures no single particle remains in contact with the hottest surface for too long, preventing localized overheating or burning.

Homogeneity of the Final Product

For applications requiring strict quality control, consistency is paramount.

By passing the material through a consistent temperature profile with continuous mixing, the rotary furnace minimizes variations between particles. This results in a batch of activated carbon where the pore development and amorphous structure are uniform throughout.

Understanding the Trade-offs

While the rotary tube furnace offers superior activation quality, it introduces variables that require precise management.

Complexity of Process Parameters

Achieving optimal results is not as simple as setting a temperature. You must control the tube rotation speed and tilt angle to govern the mixing intensity and dwell time.

Material Bed Sensitivity

The depth of the powder bed affects the process significantly. If the bed is too deep, the mixing efficiency drops; if it is too shallow, throughput suffers. You must balance feed rates and rotation speeds to maintain the ideal bed depth for gas penetration.

Making the Right Choice for Your Goal

To maximize the potential of your hydrochar activation, consider your specific operational targets:

- If your primary focus is Maximum Surface Area: Prioritize the rotary furnace to ensure the thorough gas contact required to reach specific surface areas of 200 m²/g or higher.

- If your primary focus is Product Uniformity: Use the rotary system to eliminate temperature gradients and ensure every granule undergoes the exact same thermal history.

- If your primary focus is Process Efficiency: Leverage the rotary motion to improve heat transfer rates and reduce the consumption of activating gases.

The rotary tube furnace transforms hydrochar activation from a passive baking process into an active, dynamic reaction that unlocks the material's full porosity.

Summary Table:

| Feature | Rotary Tube Furnace | Static Furnace |

|---|---|---|

| Material Bed | Dynamic/Tumbling (Continuous stirring) | Stationary (Dense/Packed bed) |

| Thermal Uniformity | High (Eliminates localized hot spots) | Low (Potential temperature gradients) |

| Gas-Solid Contact | Maximum (Active particle circulation) | Limited (Diffusion restricted to outer layers) |

| Product Consistency | Homogeneous (Uniform pore development) | Variable (Risk of 'dead zones') |

| Surface Area | High (Can exceed 200 m²/g) | Lower (Inconsistent activation) |

Elevate Your Material Activation with KINTEK Expertise

Don't let static 'dead zones' compromise your research or production quality. Backed by expert R&D and manufacturing, KINTEK offers high-performance Rotary, Muffle, Tube, Vacuum, and CVD systems designed to meet the most rigorous lab requirements. Our customizable high-temperature furnaces ensure uniform heat distribution and optimized gas-solid interaction for your unique hydrochar or carbon applications.

Ready to maximize your specific surface area and product homogeneity?

Contact KINTEK Today for a Professional Consultation

References

- Reuse of Polymeric Resin for Production of Activated Hydrochar Applied in Removal of Bisphenol A and Diclofenac Synthetic Aqueous Solution. DOI: 10.3390/coatings15010027

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What energy-saving features are present in the rotary tube sintering furnace? Boost Efficiency with Advanced Insulation and Controls

- What are the production advantages of rotary kilns? Achieve High-Quality, Efficient Industrial Processing

- What key principles make rotary kilns efficient for high-temperature processing? Unlock Optimal Thermal Processing

- What are the key features of a rotary tube furnace? Unlock Continuous, Uniform Thermal Processing

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What type of sealing technology is used in rotary kilns? Boost Efficiency & Cut Costs

- What is unique about the heating mechanism in rotary furnaces? Achieve Dynamic, Uniform Heat Transfer

- What are the scale and efficiency advantages of shaft furnace vs. rotary kiln for DRI? Maximize Your Production Output