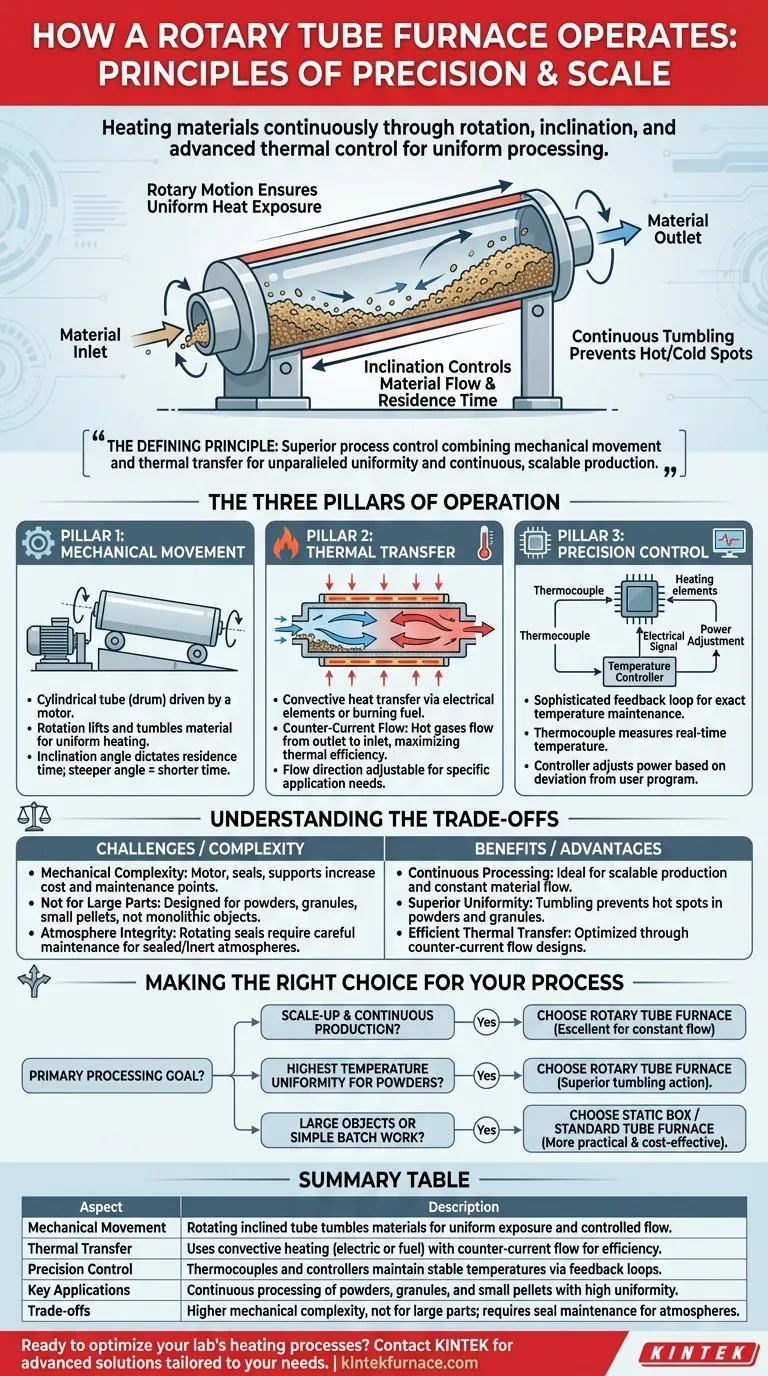

At its core, a rotary tube furnace operates by heating materials as they are continuously tumbled and transported through a rotating, slightly inclined cylindrical chamber. The combination of rotation ensures every particle is uniformly exposed to the heat, while the tilt facilitates a steady flow of material from the inlet to the outlet, making it ideal for continuous processing.

The defining principle of a rotary tube furnace is not just heating, but achieving superior process control. Its design uniquely combines mechanical movement and thermal transfer to guarantee unparalleled temperature uniformity and enable continuous, scalable production.

The Three Pillars of Operation

A rotary tube furnace's function can be broken down into three interconnected systems: mechanical movement, thermal transfer, and precision control. Each plays a critical role in the final result.

Pillar 1: Mechanical Movement

The furnace is built around a cylindrical tube, or drum, that is driven by a motor to rotate around its longitudinal axis. This tube is mounted at a slight angle.

This rotation is the key to the furnace's effectiveness. As the tube spins, the material inside is constantly lifted and tumbled, preventing any single part of the sample from being over- or under-heated.

The inclination angle dictates the residence time—the amount of time the material spends inside the heated zone. A steeper angle results in faster transport and a shorter residence time, while a shallower angle increases it.

Pillar 2: Thermal Transfer

Heat is applied to the material via convective heat transfer. This is typically achieved in one of two ways: with electrical heating elements surrounding the tube or by burning fuel to generate hot gases that flow through the tube.

A highly efficient design involves counter-current flow. In this setup, the hot gases are introduced at the material outlet and flow toward the inlet, moving in the opposite direction of the sample. This ensures the hottest gases meet the most processed material, maximizing thermal efficiency.

While counter-current is common, the gas flow direction can be changed depending on the specific application requirements, such as the need for rapid initial heating.

Pillar 3: Precision Control

Modern furnaces operate on a sophisticated feedback loop to maintain exact temperatures. A thermocouple inside the furnace measures the real-time temperature and converts it into an electrical signal.

This signal is sent to a temperature controller, which compares the actual temperature to the desired setpoint defined by the user's program.

If there is a deviation, the controller automatically adjusts the power supplied to the heating elements, ensuring the internal temperature remains stable and accurate throughout the process.

Understanding the Trade-offs

While powerful, the design of a rotary tube furnace presents specific trade-offs that are important to understand.

Mechanical Complexity vs. Simplicity

The drive motor, rotating seals, and support structure make a rotary furnace more mechanically complex than a static box or tube furnace. This can translate to higher initial costs and more potential points for maintenance over the equipment's lifetime.

Ideal for Powders, Not for Large Parts

The tumbling mechanism is designed for powders, granules, and small pellets. It is fundamentally unsuitable for processing large, solid objects or monolithic parts that cannot be tumbled.

Atmosphere Integrity

Maintaining a perfectly sealed, controlled atmosphere (e.g., inert or reactive gas) can be more challenging in a rotary furnace compared to a static one. The rotating seals at the material inlet and outlet are critical components that must be perfectly maintained to prevent leaks.

Making the Right Choice for Your Process

Deciding if this technology fits your needs comes down to your primary processing goal.

- If your primary focus is process scale-up and continuous production: A rotary tube furnace is an excellent choice, as its design is built for constant material flow.

- If your primary focus is achieving the highest temperature uniformity for powders or granules: The tumbling action is superior to static heating methods for preventing hot spots and ensuring a homogeneous product.

- If your primary focus is treating single, large objects or you require a simple, low-maintenance setup for batch work: A static box furnace or standard tube furnace is likely a more practical and cost-effective solution.

By understanding these core operational principles, you can confidently determine if a rotary tube furnace is the optimal tool to achieve your material processing goals.

Summary Table:

| Aspect | Description |

|---|---|

| Mechanical Movement | Rotating inclined tube tumbles materials for uniform exposure and controlled flow. |

| Thermal Transfer | Uses convective heating (electric or fuel) with counter-current flow for efficiency. |

| Precision Control | Thermocouples and controllers maintain stable temperatures via feedback loops. |

| Key Applications | Continuous processing of powders, granules, and small pellets with high uniformity. |

| Trade-offs | Higher mechanical complexity, not for large parts; requires seal maintenance for atmospheres. |

Ready to optimize your lab's heating processes with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're scaling up production or ensuring uniform heating for powders, our experts are here to help. Contact us today to discuss how our furnaces can enhance your material processing and drive your research forward!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control