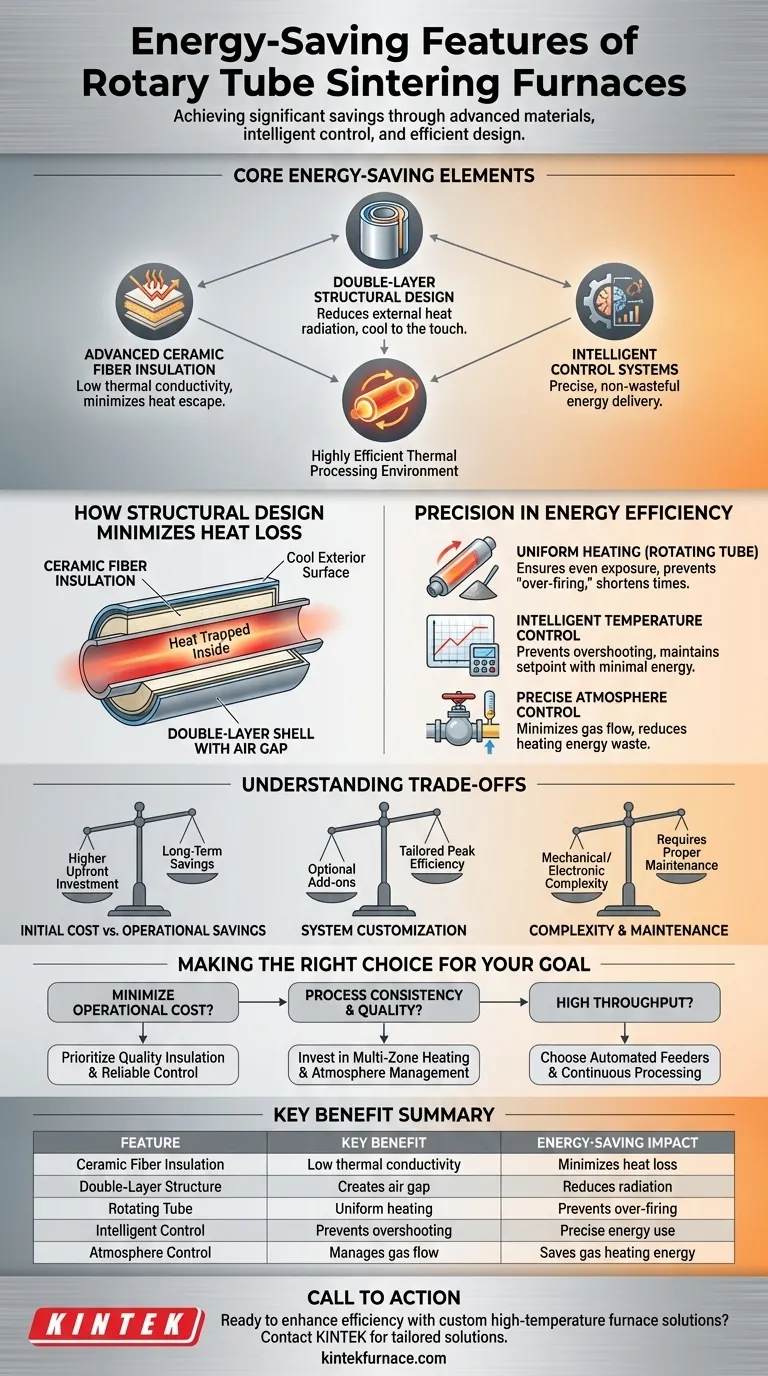

At its core, a rotary tube sintering furnace achieves significant energy savings through a combination of three primary features: the use of advanced ceramic fiber insulation, a double-layer structural design to minimize heat loss, and intelligent control systems that ensure precise, non-wasteful energy delivery. These elements work together to create a highly efficient thermal processing environment.

The energy efficiency of a rotary tube furnace isn't just a single feature, but a result of its fundamental design. By trapping heat with superior materials and ensuring that heat is used effectively through rotation and precise control, the furnace minimizes wasted energy while maximizing process quality.

How Structural Design Minimizes Heat Loss

The physical construction of the furnace is the first line of defense against energy waste. The goal is to generate heat and keep it exactly where it's needed—inside the processing tube.

Advanced Ceramic Fiber Insulation

Modern rotary tube furnaces use high-quality ceramic fiber as their primary insulation material. This material has extremely low thermal conductivity, meaning it is very poor at transferring heat.

By lining the furnace chamber with ceramic fiber, the design drastically reduces the amount of heat energy that can escape to the outer shell, keeping the thermal energy focused on the sample.

The Double-Layer Structure

Many designs incorporate a double-layer furnace shell. This creates an air gap or a secondary insulated layer between the inner chamber and the external surface.

This structure works in tandem with the ceramic insulation to keep the outer surface of the furnace cool to the touch. A cool exterior is a direct indicator that heat is being successfully contained within the system instead of radiating into the room.

The Role of Precision in Energy Efficiency

Beyond simply containing heat, a truly efficient furnace uses that heat intelligently. This is where the furnace's dynamic and control features become critical energy-saving components.

The Efficiency of Uniform Heating

The defining feature of this furnace—the rotating tube—is itself a key driver of energy efficiency. The rotation continuously tumbles and mixes the material being processed.

This action ensures every particle is exposed to the heat source evenly, creating exceptionally uniform heat distribution. Uniformity prevents the need to "over-fire" the furnace with excess energy to compensate for cold spots in a static sample, leading to shorter processing times and lower energy consumption.

Intelligent Temperature Control

These furnaces feature high-precision, intelligent control systems. They use automated programs to regulate temperature, hold it at a constant setpoint, and manage processing time.

This precision prevents temperature overshooting, a common source of energy waste where a furnace heats beyond its target and then must cool down. By delivering only the necessary power to maintain the setpoint, the system minimizes energy expenditure.

Precise Atmosphere Control

Many sintering processes require a specific, controlled atmosphere (e.g., an inert gas). The furnace's advanced control systems manage this atmosphere with precision.

By minimizing gas flow to only what is necessary, the system prevents the waste of both the gas itself and the energy required to heat that gas to the process temperature.

Understanding the Trade-offs

While highly efficient, these features come with considerations. Understanding them is key to a realistic assessment of the technology.

Initial Cost vs. Operational Savings

The high-performance materials like ceramic fiber and the sophisticated control systems contribute to a higher upfront investment compared to simpler furnace designs. The energy savings are realized over the operational lifetime of the equipment.

System Customization

Features that enhance efficiency, such as automatic feeders, multi-zone heating, or specialized gas handling packages, are often optional add-ons. A base model may be efficient, but peak efficiency is achieved through a fully integrated and customized system tailored to a specific process.

Complexity and Maintenance

The rotating mechanism and advanced control systems, while beneficial, add mechanical and electronic complexity. These systems require proper maintenance to ensure they continue to operate at peak efficiency and reliability.

Making the Right Choice for Your Goal

The most valuable energy-saving features depend entirely on your primary operational objective.

- If your primary focus is minimizing operational cost: Prioritize a furnace with the highest quality ceramic fiber insulation and a proven, reliable temperature control system.

- If your primary focus is process consistency and quality: Invest in advanced, multi-zone heating controls and precise atmosphere management, as the resulting product uniformity reduces waste and rework.

- If your primary focus is high throughput: A system with automated feeders and an integrated control system for continuous processing will yield the greatest efficiency by minimizing downtime and heat loss from loading/unloading cycles.

Ultimately, understanding how these features interrelate empowers you to select a furnace configuration that aligns directly with your technical and financial goals.

Summary Table:

| Feature | Key Benefit | Energy-Saving Impact |

|---|---|---|

| Advanced Ceramic Fiber Insulation | Low thermal conductivity | Minimizes heat loss to the environment |

| Double-Layer Structural Design | Creates air gap for insulation | Reduces external heat radiation |

| Rotating Tube Mechanism | Ensures uniform heating | Prevents over-firing and shortens process time |

| Intelligent Temperature Control | Prevents overshooting | Delivers precise energy without waste |

| Precise Atmosphere Control | Manages gas flow efficiently | Saves energy on heating gases |

Ready to enhance your lab's efficiency with a custom high-temperature furnace solution?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you save energy, reduce costs, and improve process quality.

Contact us today to discuss how our tailored furnace solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing