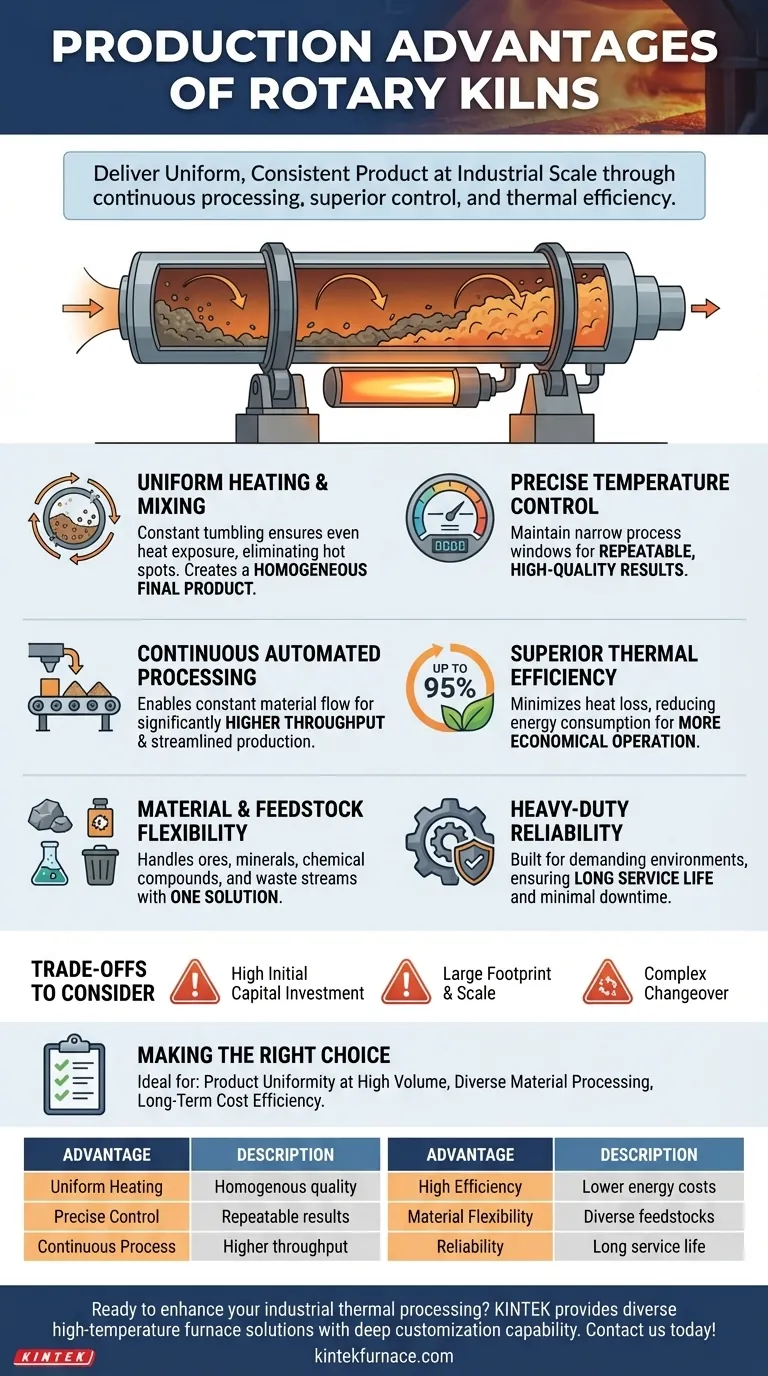

In essence, the primary production advantages of rotary kilns are their ability to deliver a highly uniform and consistent product at an industrial scale. They achieve this through a combination of continuous material processing, superior temperature control, and exceptional thermal efficiency, making them a cornerstone technology for high-volume thermal processing applications.

The core value of a rotary kiln is its power to transform a variable stream of raw material into a homogenous, high-quality final product. It excels by creating a highly controlled, repeatable thermal environment that operates continuously, ensuring both quality and throughput.

Driving Unmatched Product Quality and Consistency

For any industrial process, the ultimate goal is a predictable and high-quality output. Rotary kilns are engineered specifically to achieve this through several key mechanisms.

Uniform Heating and Mixing

The constant, gentle tumbling motion of a rotary kiln ensures that every particle of the material is exposed to the heat source evenly. This eliminates hot spots and prevents uneven firing, which are common issues in static kilns.

This continuous mixing is fundamental to creating a homogenous final product, where the desired chemical and physical properties are consistent throughout the entire batch.

Precise Temperature Control

Modern rotary kilns offer exceptionally precise temperature control, allowing operators to maintain the narrow process windows required for sensitive materials. The system can be adjusted rapidly to meet specific process requirements.

This level of control is critical for ensuring that thermal reactions proceed exactly as intended, producing repeatable, high-quality results from one run to the next.

Maximizing Throughput and Operational Efficiency

Beyond quality, production success hinges on efficiency and volume. Rotary kilns are designed for continuous, large-scale operation.

Continuous, Automated Processing

Unlike batch systems that require stopping and starting, rotary kilns enable a constant flow of material. This continuous heat treatment allows for significantly higher throughput and a more streamlined production line.

Their design also lends itself to simple, automated operation, reducing the need for constant manual intervention and minimizing operational complexity.

High-Speed Cycles

The design of rotary kilns, sometimes paired with high-pressure gas quenching systems, facilitates high-speed process cycles. This allows for rapid processing while still maintaining strict quality standards.

Superior Thermal Efficiency

Rotary kilns are known for their high thermal efficiency, with some designs achieving up to 95%. By minimizing heat loss and, in some cases, eliminating the need to heat auxiliary equipment like carts, they reduce overall energy consumption.

This efficiency translates directly into more economical operation and lower production costs over the long term.

Designed for Versatility and Reliability

A key advantage of rotary kiln technology is its adaptability to a wide range of industrial challenges.

Material and Feedstock Flexibility

Rotary kilns are not limited to a single type of material. They are engineered to handle an incredible diversity of feedstocks, from ores and minerals to chemical compounds and waste streams.

This versatility allows a single piece of equipment to be a solution for many different processing needs.

Heavy-Duty, Reliable Construction

These machines are built for demanding industrial environments. Their heavy-duty construction ensures long-term reliability and a long service life, often exceeding 15 years with proper maintenance.

This robustness means they can handle demanding process conditions continuously without frequent downtime.

Understanding the Trade-offs

While powerful, rotary kilns are not a universal solution. Their advantages are best realized when their inherent characteristics align with the production goal.

High Initial Capital Investment

The robust engineering, customization, and large scale of industrial rotary kilns mean they represent a significant upfront capital investment. They are built for long-term, high-volume production, not short-term or small-scale projects.

Footprint and Scale of Operation

Rotary kilns are large, heavy machines that require substantial physical space. Their primary strength is in continuous, high-throughput applications, making them less suitable for labs or facilities that only run very small, infrequent batches.

Changeover Complexity

While versatile in the materials they can handle, changing from one process to a completely different one can be a complex undertaking. The kiln may need to be fully cooled, cleaned, and reconfigured, which involves significant downtime.

Making the Right Choice for Your Goal

Selecting a rotary kiln depends entirely on your specific production priorities.

- If your primary focus is product uniformity at high volume: The kiln's ability to provide even heating and continuous mixing is its greatest strength.

- If your primary focus is processing diverse or difficult materials: The kiln's robust design and flexibility in handling various feedstocks make it an ideal choice.

- If your primary focus is long-term operational cost efficiency: The high thermal efficiency and potential for simplified, continuous operation will deliver significant value over the life of the equipment.

Ultimately, a rotary kiln is the right choice when your goal is to achieve consistent, large-scale thermal processing with reliability and control.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Continuous tumbling ensures even heat exposure for homogenous product quality. |

| Precise Temperature Control | Maintains narrow process windows for repeatable, high-quality results. |

| Continuous Processing | Enables constant material flow, boosting throughput and operational efficiency. |

| High Thermal Efficiency | Up to 95% efficiency reduces energy consumption and lowers operational costs. |

| Material Flexibility | Handles diverse feedstocks like ores, minerals, and chemicals with ease. |

| Reliability | Heavy-duty construction ensures long service life and minimal downtime. |

Ready to enhance your industrial thermal processing with reliable, high-efficiency solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need uniform heating, precise control, or scalable throughput, we can tailor a solution to boost your productivity and reduce costs. Contact us today to discuss how our expertise can transform your operations!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control