High-precision atmosphere tube furnaces provide a controlled, isolated environment essential for processing materials that degrade or alter chemically when exposed to air. By combining superior sealing performance with flexible airflow regulation, these systems allow you to precisely dictate the chemical reactions occurring during sintering, specifically preventing unwanted oxidation and regulating oxygen vacancy concentrations.

The Core Takeaway For atmosphere-sensitive ceramics, the sintering environment is just as critical as the temperature. A high-precision tube furnace allows you to engineer the material's fundamental properties—such as defect structures and valence states—by completely decoupling the heating process from the ambient atmosphere.

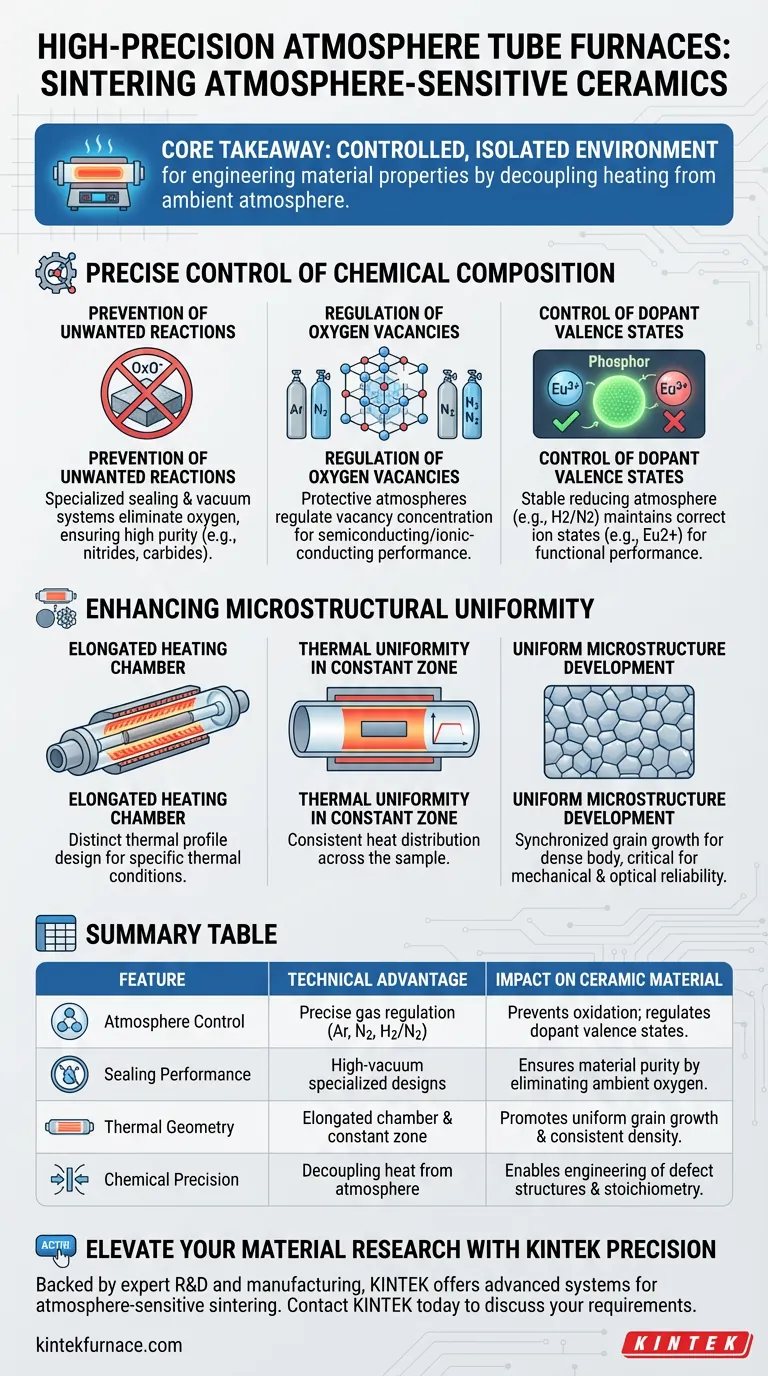

Precise Control of Chemical Composition

The primary advantage of an atmosphere tube furnace is its ability to manipulate the chemical stability of the ceramic body.

Prevention of Unwanted Reactions

Sensitive raw materials, such as nitrides and carbides, are prone to oxidation at high temperatures. High-precision tube furnaces utilize specialized sealing designs and vacuum systems to create an environment with extremely low oxygen content. This prevents the degradation of the material and ensures the synthesized product maintains high purity.

Regulation of Oxygen Vacancies

For semiconducting or ionic-conducting ceramics, the concentration of oxygen vacancies is a critical performance parameter. By utilizing specific protective atmospheres—such as high-purity argon, nitrogen, or reducing gases—you can effectively regulate these vacancies. This control prevents uncontrolled oxidation or reduction reactions that would otherwise alter the material's stoichiometry.

Control of Dopant Valence States

In functional ceramics, such as phosphors, the valence state of dopants dictates performance. For example, ensuring Europium ions remain in the Eu2+ state (rather than oxidizing to Eu3+) requires a stable reducing atmosphere (e.g., 10% H2 and 90% N2). The tube furnace maintains this specific gas mixture to drive the correct incorporation of ions into the crystal lattice.

Enhancing Microstructural Uniformity

Beyond chemical composition, the physical design of the furnace plays a vital role in the structural development of the ceramic.

The Elongated Heating Chamber

Atmosphere tube furnaces typically feature an elongated heating chamber. This geometry is distinct from box or muffle furnaces and is engineered to create a specific thermal profile.

Thermal Uniformity in the Constant Zone

Within the elongated chamber, there is a designated "constant temperature zone." This ensures that the ceramic sample experiences consistent heat distribution.

Uniform Microstructure Development

Thermal uniformity is essential for synchronized grain growth. By eliminating thermal gradients across the sample, the furnace promotes the uniform development of the ceramic microstructure. This results in a dense body with consistent grain size, which is critical for mechanical and optical reliability.

Understanding the Trade-offs

While atmosphere tube furnaces offer superior control, it is important to understand when their features are necessary versus when a simpler alternative might suffice.

Atmosphere Complexity vs. Simple Oxidation

If your material requires a stable oxidizing environment (like sintering standard Alumina), a high-temperature box or muffle furnace is often more appropriate. These standard furnaces naturally provide an air atmosphere that maintains stoichiometry for oxide ceramics without the need for complex gas regulation systems or vacuum pumps.

Throughput Limitations

The elongated tube design prioritizes uniformity and atmosphere control over volume. Unlike box furnaces which can accommodate larger batches of bulk materials, tube furnaces are generally limited by the diameter of the tube, making them ideal for high-value, sensitive materials rather than bulk processing of inert ceramics.

Making the Right Choice for Your Goal

To maximize the quality of your ceramic sintering, align the furnace capabilities with your material's specific chemical needs.

- If your primary focus is Functional Performance (e.g., Luminescence/Conductivity): Choose the atmosphere tube furnace to strictly control valence states (like Eu2+) and oxygen vacancy concentrations using reducing or inert gases.

- If your primary focus is Material Purity (e.g., Non-oxides): Rely on the tube furnace’s high-vacuum sealing capabilities to prevent the oxidation of sensitive nitrides or carbides.

- If your primary focus is Standard Oxide Densification: Consider a standard box furnace, as the ambient air provides the necessary oxidizing environment for materials like alumina.

Ultimately, the high-precision atmosphere tube furnace is not just a heat source; it is a chemical reactor designed to protect and define the fundamental structure of your material.

Summary Table:

| Feature | Technical Advantage | Impact on Ceramic Material |

|---|---|---|

| Atmosphere Control | Precise regulation of gas (Ar, N2, H2/N2) | Prevents oxidation; regulates dopant valence states (e.g., Eu2+) |

| Sealing Performance | High-vacuum specialized sealing designs | Ensures material purity by eliminating ambient oxygen interference |

| Thermal Geometry | Elongated chamber & constant temp zone | Promotes uniform grain growth and consistent microstructure density |

| Chemical Precision | Decoupling heat from ambient atmosphere | Enables engineering of defect structures and stoichiometry |

Elevate Your Material Research with KINTEK Precision

Don't let uncontrolled oxidation compromise your high-performance ceramics. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of atmosphere-sensitive sintering.

Whether you are developing next-generation phosphors, semiconductors, or non-oxide ceramics, our customizable high-temperature furnaces provide the chemical and thermal stability your research requires. Contact KINTEK today to discuss your specific process requirements and discover how our specialized lab solutions can enhance your material quality and consistency.

Visual Guide

References

- Beatriz Monteiro, Sónia Simões. Microstructure and Mechanical Properties of Ti6Al4V to Al2O3 Brazed Joints Using Ti-Ag/Cu-Ti Thin Films. DOI: 10.3390/met14020146

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a tube furnace in the pyrolysis of biomass? Achieve Precision in Material Research

- What is a tube furnace and what are its primary uses? Essential for Controlled High-Temperature Processes

- How does a multi-zone furnace work? Achieve Personalized Comfort and Energy Efficiency

- How does a high-temperature tube furnace contribute to the synthesis of nitrogen-doped graphene? Boost Your Lab Results

- What is the core function of a horizontal tube furnace in Sb2Se3 nanowire prep? Master Thermal Gradients for APVT

- Why is pre-oxidation treatment of the substrate in a tube furnace necessary? Ensure Strong Ti(Nb)-Si-C Coating Adhesion

- What is the primary function of a high-temperature vacuum tube furnace for Gr-NDs? Mastering Carbon Phase Transitions

- What are the benefits of Tube Furnaces? Achieve Precision, Control, and Versatility in Thermal Processing