In essence, a tube furnace is a high-temperature electric furnace designed around a central ceramic or quartz tube. Its primary purpose is to heat samples with exceptional uniformity and precision, often within a tightly controlled atmosphere. This makes it an indispensable tool for advanced materials science, chemical synthesis, and high-temperature testing where exposure to air must be prevented.

The defining advantage of a tube furnace is its ability to combine uniform high-temperature heating with precise atmospheric control. While other furnaces provide heat, a tube furnace provides a controlled environment at temperature, which is critical for sensitive processes.

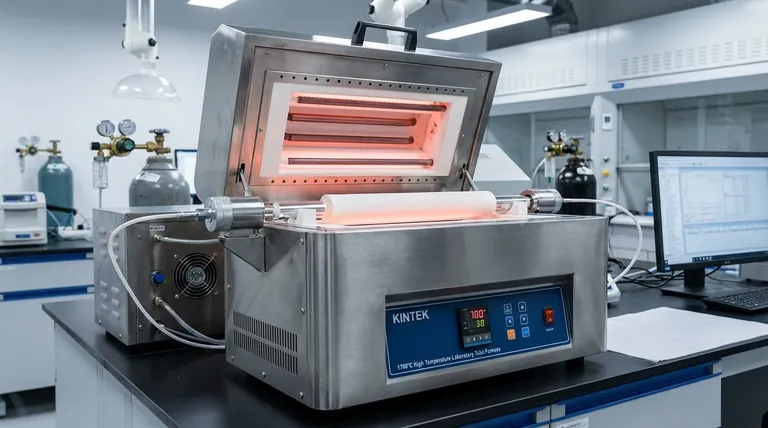

The Anatomy of a Tube Furnace

A tube furnace's design is elegantly simple and focused on its core functions: providing uniform heat and isolating the sample. Understanding its key components reveals why it is so effective.

The Core Components

A standard tube furnace consists of three main parts. First, heating elements (like molybdenum disilicide or silicon carbide) surround the central tube. Second is the process tube itself, typically made of high-purity alumina, quartz, or mullite, which contains the sample. Finally, a programmable controller manages the temperature with high precision.

The Principle of Uniform Heating

The cylindrical chamber is the key to its performance. By arranging the heating elements around the tube, the furnace delivers radiant heat evenly from all sides. This ensures the entire sample experiences the same temperature, which is critical for processes like crystal growth and annealing where temperature gradients can ruin the result.

The Power of Atmosphere Control

This is the feature that truly distinguishes a tube furnace. The ends of the tube can be sealed with flanges, allowing you to control the gaseous environment inside. You can pull a vacuum to remove reactive gases like oxygen, or you can flow a specific gas—such as an inert gas (argon, nitrogen) to prevent reactions or a reactive gas to participate in a chemical process.

Where Tube Furnaces Excel: Key Applications

The combination of uniform heat and atmosphere control makes tube furnaces uniquely suited for a range of sophisticated scientific and industrial tasks.

Material Synthesis and Purification

Many modern materials cannot be created in open air. A tube furnace is essential for Chemical Vapor Deposition (CVD), where gases react at high temperatures to deposit a thin film onto a substrate. It is also used for growing high-purity crystals and synthesizing or purifying chemical compounds that would otherwise oxidize.

Advanced Heat Treatment

Heat treatment modifies a material's microstructure to improve its physical properties. A tube furnace is ideal for annealing, which softens materials and relieves internal stresses, and sintering, which fuses powders into a solid mass. Performing these under a vacuum or inert gas prevents oxidation and ensures material purity.

Thermal Analysis and Testing

Researchers use tube furnaces to study how materials behave at extreme temperatures. This includes pyrolysis, the thermal decomposition of materials in the absence of oxygen, and testing the performance of fuel cells, catalysts, and high-performance composites in specific, controlled environments.

Understanding the Trade-offs: Tube vs. Muffle Furnace

Choosing the right furnace depends entirely on the requirements of your process. The most common alternative to a tube furnace is a muffle furnace, and their differences are critical.

When to Use a Tube Furnace

A tube furnace is the correct choice when atmosphere control is non-negotiable. If your process is sensitive to oxygen or requires a specific reactive gas, a tube furnace is the only reliable option. It is also superior for small, uniform samples where precise temperature distribution is paramount.

When a Muffle Furnace is a Better Fit

A muffle furnace is essentially a heated box chamber that heats samples in ambient air. It is the better tool for general-purpose heating, ashing (burning off organic material), or heat-treating larger or irregularly shaped objects that don't require a special atmosphere. They are often simpler and more cost-effective for these tasks.

Core Distinctions at a Glance

The choice is simple: if you need to control the gas around your sample, you need a tube furnace. If you just need to heat a sample in air, a muffle furnace is usually sufficient and more practical.

Making the Right Choice for Your Process

Your process requirements will dictate the correct tool. Use these guidelines to make a clear decision.

- If your primary focus is atmosphere control for synthesis or purification (CVD, crystal growth, vacuum annealing): A tube furnace is essential for creating the required inert or reactive environment.

- If your primary focus is high-temperature heat treatment in air (ashing, simple ceramic firing, hardening metals): A muffle furnace is more practical, cost-effective, and can accommodate larger samples.

- If your primary focus is uniform heating of a small sample (calibration, testing thermal properties): A tube furnace provides superior temperature uniformity, but a muffle furnace may be adequate if air exposure is acceptable.

Ultimately, the decision hinges on whether your material can be exposed to air at high temperatures.

Summary Table:

| Aspect | Tube Furnace | Muffle Furnace |

|---|---|---|

| Atmosphere Control | Yes (vacuum, inert/reactive gases) | No (ambient air) |

| Heating Uniformity | High (radiant heat from all sides) | Moderate |

| Primary Uses | CVD, crystal growth, vacuum annealing, pyrolysis | Ashing, general heating, simple firing |

| Ideal For | Sensitive processes requiring gas control | Processes in air with larger samples |

Unlock Precision in Your Lab with KINTEK Tube Furnaces

Are you working on advanced materials synthesis, chemical vapor deposition (CVD), or high-temperature testing that demands exact atmosphere control? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Enhance your research with uniform heating and reliable performance—contact us today to discuss how we can tailor a solution for your needs!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision