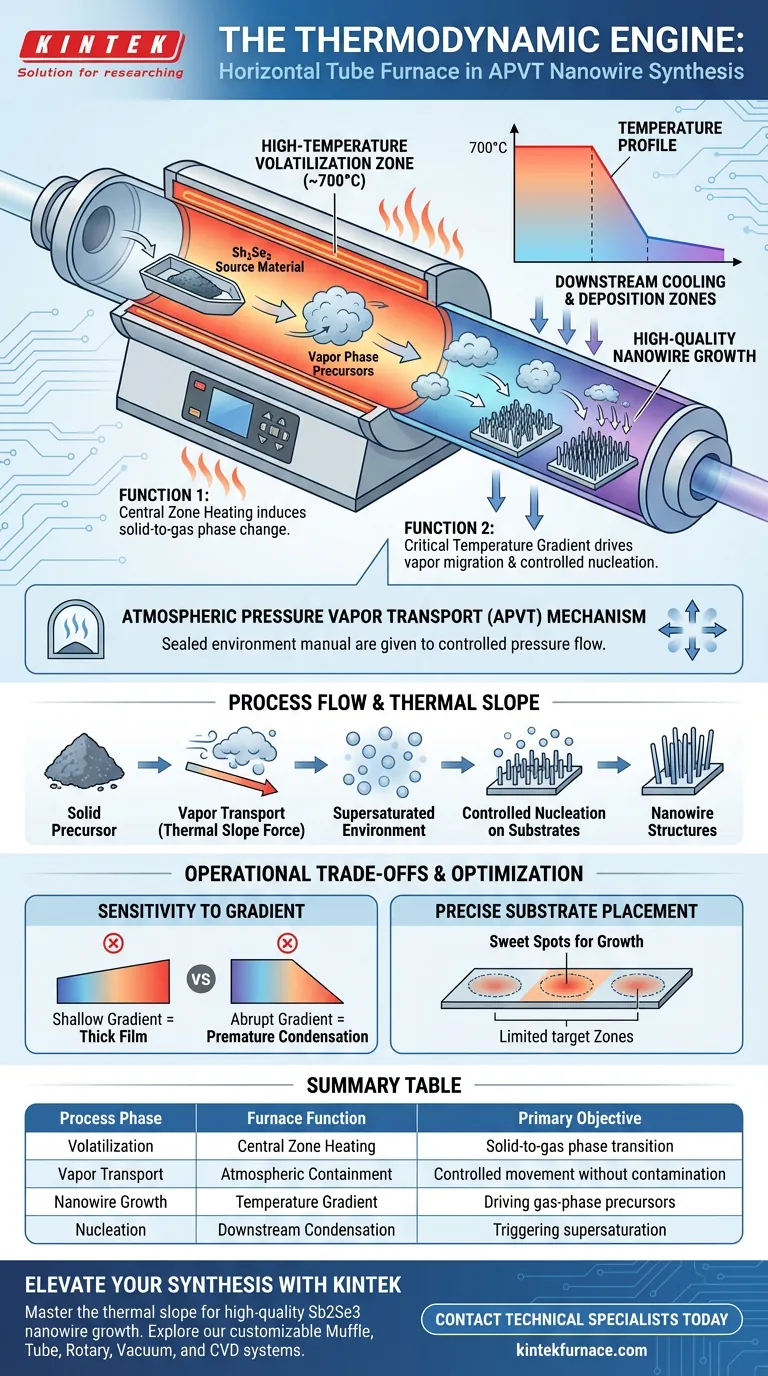

The horizontal tube furnace serves as the thermodynamic engine for the synthesis of Antimony Selenide (Sb2Se3) nanowires. It creates a dual-function environment that first volatilizes the source material at high heat and subsequently directs its transport and deposition. This precise thermal management enables the Atmospheric Pressure Vapor Transport (APVT) mechanism to function within a single chamber.

The furnace’s primary value lies in generating a precise temperature gradient; this thermal slope drives the migration of gas-phase precursors from the hot center to cooler downstream regions, forcing the nucleation of high-quality nanowires.

Establishing the Thermal Environment

High-Temperature Volatilization

The furnace functions by maintaining a central heating zone at a specific, high temperature, typically around 700°C.

This intense heat is required to induce the phase change of the Sb2Se3 source material. It converts the solid precursor into a volatile gas phase, making it available for transport.

Controlled Atmospheric Containment

The tube configuration isolates the reaction environment from external variables.

By sealing the process, the furnace ensures that the vapor transport occurs under controlled atmospheric pressure (APVT), preventing contamination during the sublimation process.

Driving Nanowire Formation

The Critical Temperature Gradient

Unlike an oven designed for uniform heating, the horizontal tube furnace is utilized to establish a temperature gradient along the length of the tube.

The temperature remains highest at the source and drops significantly toward the downstream regions. This "thermal slope" is the physical force that drives the movement of the vapor.

Downstream Condensation and Growth

As the volatilized precursors travel into the lower-temperature zones, the gas creates a supersaturated environment.

This change in thermodynamic conditions triggers condensation on the substrates placed in these cooler regions. Instead of forming a bulk solid, the controlled nucleation allows the material to organize into high-quality nanowire structures.

Understanding the Operational Trade-offs

Sensitivity to Gradient Fluctuations

The success of nanowire growth is heavily dependent on the stability of the temperature drop.

If the gradient is too shallow, the material may deposit as a thick film rather than discrete wires. Conversely, if the temperature drops too abruptly, the vapor may condense prematurely before reaching the substrate.

Limited Deposition Zones

Horizontal tube furnaces possess specific "sweet spots" where the temperature is ideal for nanowire growth.

This creates a spatial limitation; substrates must be placed at exact coordinates within the downstream tube to achieve uniform growth, limiting the total batch size per run.

Optimizing Your Synthesis Strategy

To achieve the best results with APVT synthesis, you must align your furnace settings with your specific output goals.

- If your primary focus is precursor conversion: Calibrate the central zone strictly to the volatilization temperature (e.g., 700°C) to ensure the source material fully enters the vapor phase.

- If your primary focus is nanowire morphology: Map the downstream temperature profile to identify the precise distance from the center where the thermal gradient supports nucleation.

Success in APVT relies not just on heating the material, but on mastering the thermal slope that guides its reconstruction.

Summary Table:

| Process Phase | Furnace Function | Primary Objective |

|---|---|---|

| Volatilization | Central Zone Heating (~700°C) | Solid-to-gas phase transition of Sb2Se3 source |

| Vapor Transport | Atmospheric Containment | Controlled movement of precursors without contamination |

| Nanowire Growth | Temperature Gradient | Driving gas-phase precursors to cooler deposition zones |

| Nucleation | Downstream Condensation | Triggering supersaturation for high-quality nanowire formation |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the heartbeat of Atmospheric Pressure Vapor Transport (APVT). At KINTEK, we understand that mastering the thermal slope is critical for high-quality Antimony Selenide (Sb2Se3) nanowire growth.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are fully customizable to meet your unique research needs, ensuring stable temperature gradients and contamination-free environments for every run.

Ready to optimize your synthesis results? Contact our technical specialists today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Atmospheric Pressure Vapor Transport Deposition of Sb<sub>2</sub>Se<sub>3</sub> Nanowires and Their Application in Photodetection. DOI: 10.1002/admt.202500722

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What physical conditions does a dual-zone tube furnace provide for CVT? Master Precision Thermal Gradient Control

- What role does a single-zone tube furnace play in synthesizing ZnPS3? Master the Thermal Profile for Layered Materials

- In what scenarios are laboratory high-temperature tube furnaces or muffle furnaces utilized? Study MgTiO3-CaTiO3 Ceramics

- Why is an industrial-grade tube furnace utilized for the heat treatment of TiO2 particles under an argon atmosphere?

- How is a tube high-temperature furnace utilized in the preparation of NiSA-O/Mo2C catalysts? Expert Synthesis Guide

- What technical conditions does a vacuum tube furnace provide for carbon xerogel? Master High-Performance Carbonization

- What is the role of a tube furnace during fuel cell feasibility studies? Optimize Your Thermal Control

- What are the types of Tube Furnaces based on orientation? Horizontal vs. Vertical for Optimal Thermal Processing