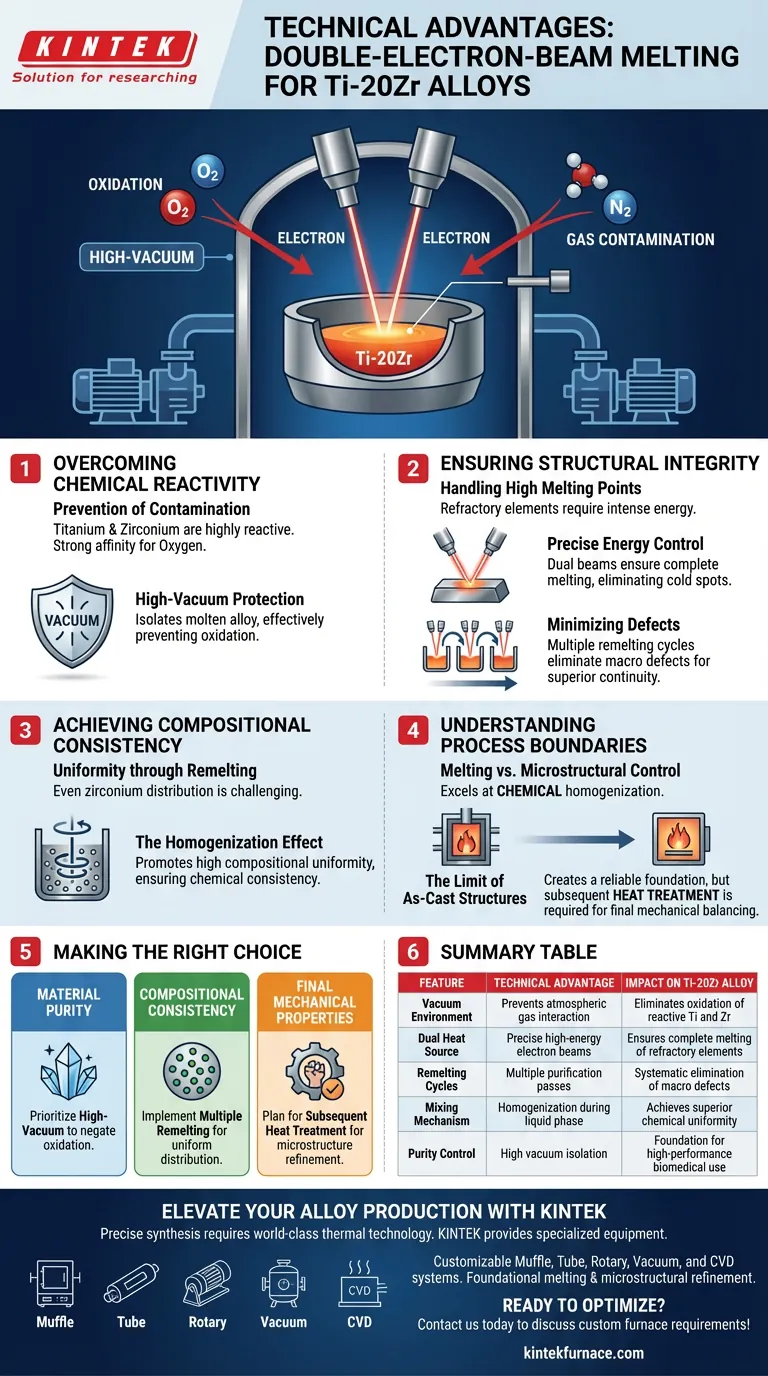

The primary technical advantage of using a double-electron-beam melting furnace for Ti-20Zr alloys is its ability to maintain a high-vacuum environment combined with precise high-energy heat application. This specific configuration prevents the detrimental oxidation of highly reactive metals like titanium and zirconium while ensuring the complete melting and mixing of these high-melting-point elements.

The double-electron-beam melting process serves as a critical purification and homogenization step. By eliminating gas contamination and macro defects through multiple remelting cycles, it produces a chemically uniform ingot that serves as a reliable foundation for high-performance biomedical applications.

Overcoming Chemical Reactivity

Prevention of Contamination

Titanium and zirconium are classified as active metals. They possess a strong affinity for oxygen and other gases when heated.

High-Vacuum Protection

The double-electron-beam furnace operates under high vacuum conditions. This isolates the molten alloy from the atmosphere, effectively preventing oxidation and gas contamination during synthesis.

Ensuring Structural Integrity

Handling High Melting Points

Ti-20Zr alloys consist of refractory elements that require intense thermal energy to transition from solid to liquid.

Precise Energy Control

This furnace utilizes high-energy electron beams as its heat source. This technology offers precise control over the energy input, ensuring that even these high-melting-point metals are fully melted without localized cold spots.

Minimizing Defects

Through the use of multiple remelting cycles, the process systematically eliminates macro defects. This results in an ingot with superior structural continuity compared to single-pass melting methods.

Achieving Compositional Consistency

Uniformity through Remelting

In alloy synthesis, ensuring that the zirconium is evenly distributed within the titanium matrix is a significant challenge.

The Homogenization Effect

The double-electron-beam furnace promotes high compositional uniformity. The repeated melting cycles act as a mixing mechanism, producing an alloy ingot that is chemically consistent throughout its volume.

Understanding the Process Boundaries

Melting vs. Microstructural Control

It is distinct to note that while this furnace excels at chemical homogenization and purification, it is primarily a melting tool.

The Limit of As-Cast Structures

The furnace creates a reliable foundation, but it does not necessarily optimize the atomic diffusion required for final mechanical balancing.

As noted in supplementary contexts regarding tubular furnaces, distinct heat treatment processes are often required after melting. These subsequent steps promote atomic diffusion and eliminate microscopic segregation to fully balance mechanical strength and corrosion resistance.

Making the Right Choice for Your Goal

To maximize the quality of your Ti-20Zr alloy, align your process parameters with your specific quality requirements:

- If your primary focus is material purity: Prioritize the high-vacuum capabilities of the electron beam furnace to negate the risk of oxidation and gas absorption.

- If your primary focus is compositional consistency: Implement multiple remelting cycles within the furnace to ensure the zirconium is uniformly distributed within the titanium.

- If your primary focus is final mechanical properties: Recognize that electron beam melting is the foundational step; plan for subsequent heat treatment to refine the microstructure.

The double-electron-beam furnace provides the essential, defect-free canvas upon which high-performance alloy properties are built.

Summary Table:

| Feature | Technical Advantage | Impact on Ti-20Zr Alloy |

|---|---|---|

| Vacuum Environment | Prevents atmospheric gas interaction | Eliminates oxidation of reactive Ti and Zr |

| Dual Heat Source | Precise high-energy electron beams | Ensures complete melting of refractory elements |

| Remelting Cycles | Multiple purification passes | Systematic elimination of macro defects |

| Mixing Mechanism | Homogenization during liquid phase | Achieves superior chemical uniformity |

| Purity Control | High vacuum isolation | Foundation for high-performance biomedical use |

Elevate Your Alloy Production with KINTEK

Precise synthesis of reactive metals like Ti-20Zr requires world-class thermal technology. KINTEK provides the specialized equipment needed to bridge the gap between raw materials and high-performance alloys.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory or industrial needs. Whether you require foundational melting or subsequent microstructural refinement, our high-temp furnaces ensure your materials meet the most rigorous standards.

Ready to optimize your synthesis process? Contact us today to discuss your custom furnace requirements with our engineering team!

Visual Guide

References

- Iosif Hulka, Julia Claudia Mirza Rosca. Electrochemical Study and Mechanical Properties of Ti-Zr Alloy for Biomedical Applications. DOI: 10.3390/cryst14060493

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the primary function of a Vacuum Arc Furnace in the preparation of Ti-6Al-4V and Ti-6Al-7Nb alloys?

- What factors influence the efficiency of induction heating? Optimize Your Process for Maximum Energy Transfer

- What are the key features of high temperature melt furnaces? Achieve Precise Melting for Metals and Alloys

- What are the key benefits of using an IGBT Vacuum Induction Melting Furnace? Achieve Superior Metal Purity and Control

- What role does a Vacuum Induction Furnace play in solid-state hydrogen storage? Enhance Alloy Purity and Precision

- What are the key application requirements for the vacuum induction furnace? Ensure Safe, High-Purity Metal Processing

- How does induction heating contribute to environmental sustainability? Boost Efficiency & Cut Emissions

- What is an IGBT induction furnace? Unlock Modern Efficiency in Metal Melting