In short, induction heating contributes to environmental sustainability by being exceptionally energy-efficient, eliminating the direct use of fossil fuels and their emissions, and drastically reducing material waste through its precise, targeted application of heat. This combination not only lowers a facility's carbon footprint but also creates a cleaner, safer work environment.

Induction heating's sustainability goes beyond simply switching from gas to electric. It represents a fundamental process improvement, where precision and control inherently lead to less energy consumption, less material scrap, and zero localized emissions, aligning operational excellence with environmental responsibility.

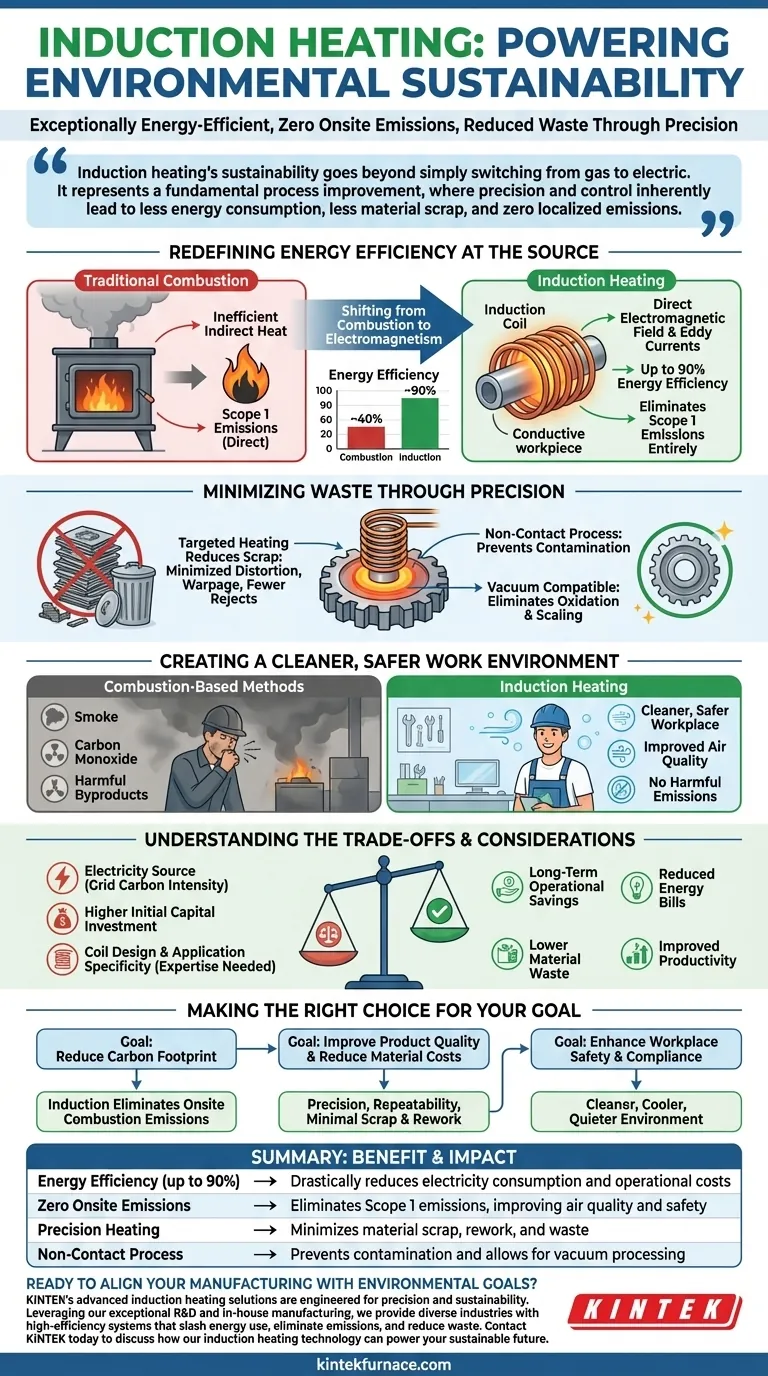

Redefining Energy Efficiency at the Source

The primary environmental benefit of induction heating stems from its fundamentally different method of generating heat. It moves away from inefficient combustion toward direct, targeted energy transfer.

Shifting from Combustion to Electromagnetism

Traditional furnaces burn fossil fuels to heat an entire chamber, which then transfers that heat to the material. This is an indirect and wasteful process.

Induction heating uses an alternating current in a copper coil to create an electromagnetic field. This field induces eddy currents directly within the conductive workpiece, generating heat instantly and precisely where it is needed.

Achieving High Energy Conversion

Because the heat is generated inside the part itself, very little energy is lost to the surrounding environment. This process can achieve an energy efficiency of up to 90%.

This means a far greater percentage of the electricity drawn from the grid is converted into useful heat, dramatically reducing overall energy consumption compared to gas-fired alternatives.

The Impact on Carbon Footprints

By replacing onsite fossil fuel combustion with high-efficiency electricity, induction heating eliminates Scope 1 emissions (direct emissions) entirely.

This directly lowers a company's carbon footprint, simplifies emissions reporting, and provides a clear path toward meeting carbon neutrality targets and other environmental regulations.

Minimizing Waste Through Precision

Sustainability is also about conserving resources. Induction heating's accuracy is a key driver of material efficiency, reducing waste at multiple stages of production.

Targeted Heating Reduces Scrap

The process is extremely localized, heating only the portion of the material inside the coil. This prevents unwanted heat from affecting other areas of the part.

This precision minimizes distortion, warpage, and other heat-related defects, significantly lowering reject rates and the need for costly rework. Fewer rejected parts means less wasted material, energy, and labor.

Eliminating Contamination and Oxidation

Induction heating is a non-contact process. The part never touches the heating element, which prevents contamination.

Furthermore, the process can be performed in a vacuum, which completely eliminates oxidation and scaling. This results in a higher-quality finished product and prevents material loss that would otherwise be scrapped.

Creating a Cleaner, Safer Work Environment

A sustainable operation also considers the well-being of its people. Induction heating creates a significantly better workplace compared to combustion-based methods.

Eliminating Harmful Byproducts

Combustion furnaces release smoke, carbon monoxide, and other harmful byproducts into the work area.

Induction produces no such emissions. It is a clean process that removes airborne contaminants, directly improving the air quality for all personnel in the facility.

Understanding the Trade-offs and Considerations

While highly beneficial, adopting induction heating requires a clear-eyed evaluation of its context and limitations.

The Source of Your Electricity Matters

The "green" credentials of induction heating are directly tied to the carbon intensity of your electrical grid. If your electricity is generated primarily from fossil fuels like coal, you are shifting emissions from your facility to the power plant.

However, the high efficiency of induction means the overall carbon footprint is still often lower, and it positions your operation to become fully carbon-neutral as the grid transitions to renewable sources.

Higher Initial Capital Investment

Induction heating systems can have a higher upfront cost compared to traditional furnace technologies. This investment must be weighed against the long-term operational savings from reduced energy bills, lower material waste, and improved productivity.

Coil Design and Application Specificity

Induction is not a universal plug-and-play solution. The inductor coil must be carefully designed and matched to the geometry of the part being heated for maximum efficiency. This requires engineering expertise and may add complexity for operations with a high mix of different parts.

Making the Right Choice for Your Goal

Adopting induction heating is a strategic decision. Your primary goal will determine how you value its benefits.

- If your primary focus is reducing your direct carbon footprint: Induction is an ideal choice, as it eliminates onsite combustion and its associated emissions entirely.

- If your primary focus is improving product quality and reducing material costs: The precision, repeatability, and control of induction will deliver significant returns by minimizing scrap, rework, and material defects.

- If your primary focus is enhancing workplace safety and compliance: Induction provides an immediate and measurable improvement by creating a cleaner, cooler, and quieter work environment free from combustion fumes.

Ultimately, induction heating offers a powerful pathway to merge advanced manufacturing capabilities with genuine environmental sustainability.

Summary Table:

| Benefit | Impact on Sustainability |

|---|---|

| Energy Efficiency (up to 90%) | Drastically reduces electricity consumption and operational costs. |

| Zero Onsite Emissions | Eliminates Scope 1 emissions, improving air quality and safety. |

| Precision Heating | Minimizes material scrap, rework, and waste. |

| Non-Contact Process | Prevents contamination and allows for vacuum processing to eliminate oxidation. |

Ready to align your manufacturing with environmental goals?

KINTEK's advanced induction heating solutions are engineered for precision and sustainability. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse industries with high-efficiency systems that slash energy use, eliminate emissions, and reduce waste.

Our expertise in customizing induction heating systems ensures a perfect fit for your unique operational requirements, helping you achieve carbon neutrality targets and improve workplace safety.

Contact KINTEL today to discuss how our induction heating technology can power your sustainable future.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability