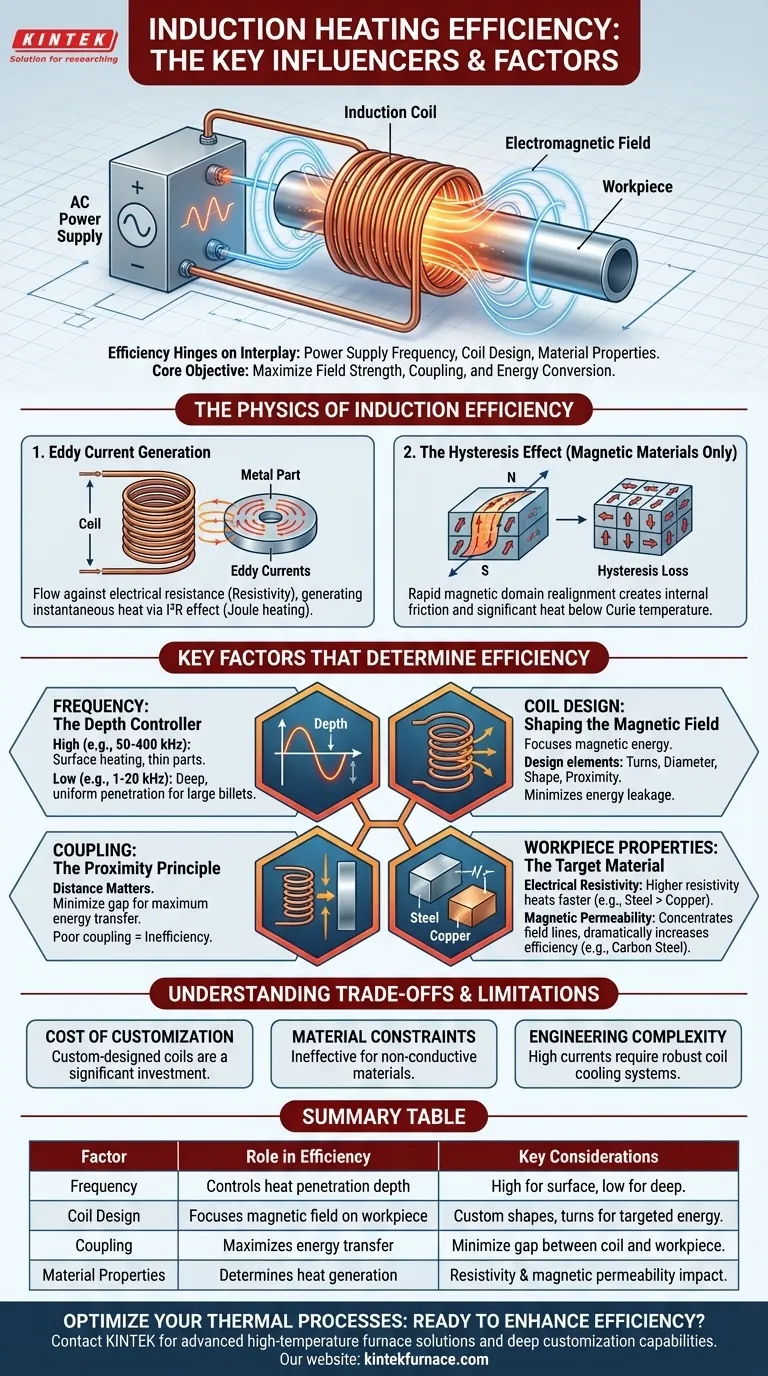

Ultimately, the efficiency of an induction heating system hinges on a precise interplay between the power supply's frequency, the induction coil's design, and the physical properties of the material being heated. The core objective is to generate the strongest possible electromagnetic field and couple it as effectively as possible with the workpiece. The material's resistance and magnetic properties then determine how efficiently that coupled energy is converted into heat.

The central challenge of induction heating is not merely generating heat, but controlling where and how deep that heat is generated. True efficiency comes from precisely matching the system's frequency and coil geometry to the material properties and the desired heating outcome, minimizing wasted energy.

The Physics of Induction Efficiency

Induction heating works through two primary mechanisms. The efficiency of your process depends on how well you leverage one or both of these effects.

Eddy Current Generation

An alternating current (AC) flowing through the induction coil creates a fluctuating magnetic field. When a conductive workpiece is placed within this field, it induces small, circular electrical currents within the material, known as eddy currents.

These eddy currents flow against the material's electrical resistance, generating precise and instantaneous heat through the I²R effect (Joule heating). The higher the material's resistivity, the more heat is generated for a given eddy current.

The Hysteresis Effect (Magnetic Materials Only)

For magnetic materials like iron and steel, a second heating mechanism occurs. The rapidly changing magnetic field forces the magnetic domains within the material to rapidly flip their alignment.

This internal friction creates significant heat. This hysteresis loss adds to the heat from eddy currents, making magnetic materials exceptionally efficient to heat with induction, but only below their Curie temperature (the point at which they lose their magnetic properties).

Key Factors That Determine Efficiency

Optimizing your process requires a clear understanding of four interconnected variables.

Frequency: The Depth Controller

The frequency of the AC power supply is the single most important parameter for controlling the depth of heat penetration.

- High Frequencies (e.g., 50 kHz - 400 kHz): The induced currents stay close to the surface of the workpiece. This is ideal for applications like surface hardening, case hardening, or brazing thin components.

- Low Frequencies (e.g., 1 kHz - 20 kHz): The magnetic field penetrates deeper into the workpiece, generating heat more uniformly throughout its mass. This is used for through-heating large billets or forging applications.

Coil Design: Shaping the Magnetic Field

The induction coil acts as the lens, focusing the magnetic energy onto the workpiece. Its design is critical for efficiency and heating pattern.

Key design elements include the number of turns, the coil's diameter and shape, and its proximity to the part. A well-designed coil concentrates the magnetic flux directly onto the area you intend to heat, minimizing energy leakage into the surrounding environment.

Coupling: The Proximity Principle

Coupling refers to the distance between the induction coil and the workpiece. The strength of the magnetic field diminishes rapidly with distance.

Therefore, for maximum energy transfer and efficiency, the gap between the coil and the workpiece should be as small as practically possible. Poor coupling is one of the most common sources of inefficiency in an induction process.

Workpiece Properties: The Target Material

The material itself dictates how it will respond to the induced magnetic field.

- Electrical Resistivity: Materials with higher resistivity (like steel) heat more efficiently than materials with very low resistivity (like copper or aluminum) because they offer more resistance to the flow of eddy currents.

- Magnetic Permeability: Materials with high magnetic permeability (like carbon steel) concentrate the magnetic field lines, dramatically increasing the efficiency of both eddy current and hysteresis heating.

Understanding the Trade-offs and Limitations

While powerful, induction heating is not a universal solution, and achieving high efficiency comes with specific challenges.

The Cost of Customization

Optimal efficiency for a specific part or process almost always requires a custom-designed induction coil. The engineering and manufacturing of these specialized copper coils can be a significant investment, especially for complex geometries.

Material Constraints

Induction heating is fundamentally reliant on the workpiece being electrically conductive. It is ineffective for heating non-conductive materials like ceramics, plastics, or glass unless a conductive "susceptor" is used to transfer heat indirectly.

Engineering Complexity

The high currents flowing through the induction coil (often hundreds of amps) generate significant heat in the coil itself. This represents a loss of energy and requires robust, integrated cooling systems, typically using circulated water, which adds to the system's overall complexity and maintenance requirements.

Making the Right Choice for Your Goal

To optimize your process, align your system parameters with your specific heating objective.

- If your primary focus is surface hardening a steel gear: Use a high frequency and a tightly coupled coil shaped to match the gear's profile to heat only the surface layer.

- If your primary focus is through-heating a large aluminum billet for forging: Use a lower frequency for deep penetration and a multi-turn solenoid coil to ensure uniform heating.

- If your primary focus is brazing two complex copper components: Invest in a custom-designed coil that delivers heat precisely to the joint area, maximizing energy transfer and minimizing heat-up time.

By understanding these core principles, you gain direct control over the heat, transforming it from a brute-force tool into a precision instrument.

Summary Table:

| Factor | Role in Efficiency | Key Considerations |

|---|---|---|

| Frequency | Controls heat penetration depth | High for surface heating, low for deep heating |

| Coil Design | Focuses magnetic field on workpiece | Custom shapes and turns for targeted energy |

| Coupling | Maximizes energy transfer | Minimize gap between coil and workpiece |

| Material Properties | Determines heat generation | Resistivity and magnetic permeability impact efficiency |

Ready to enhance your induction heating efficiency? Contact KINTEK today to leverage our exceptional R&D and in-house manufacturing for advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and industrial needs. Get in touch now to optimize your thermal processes!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication