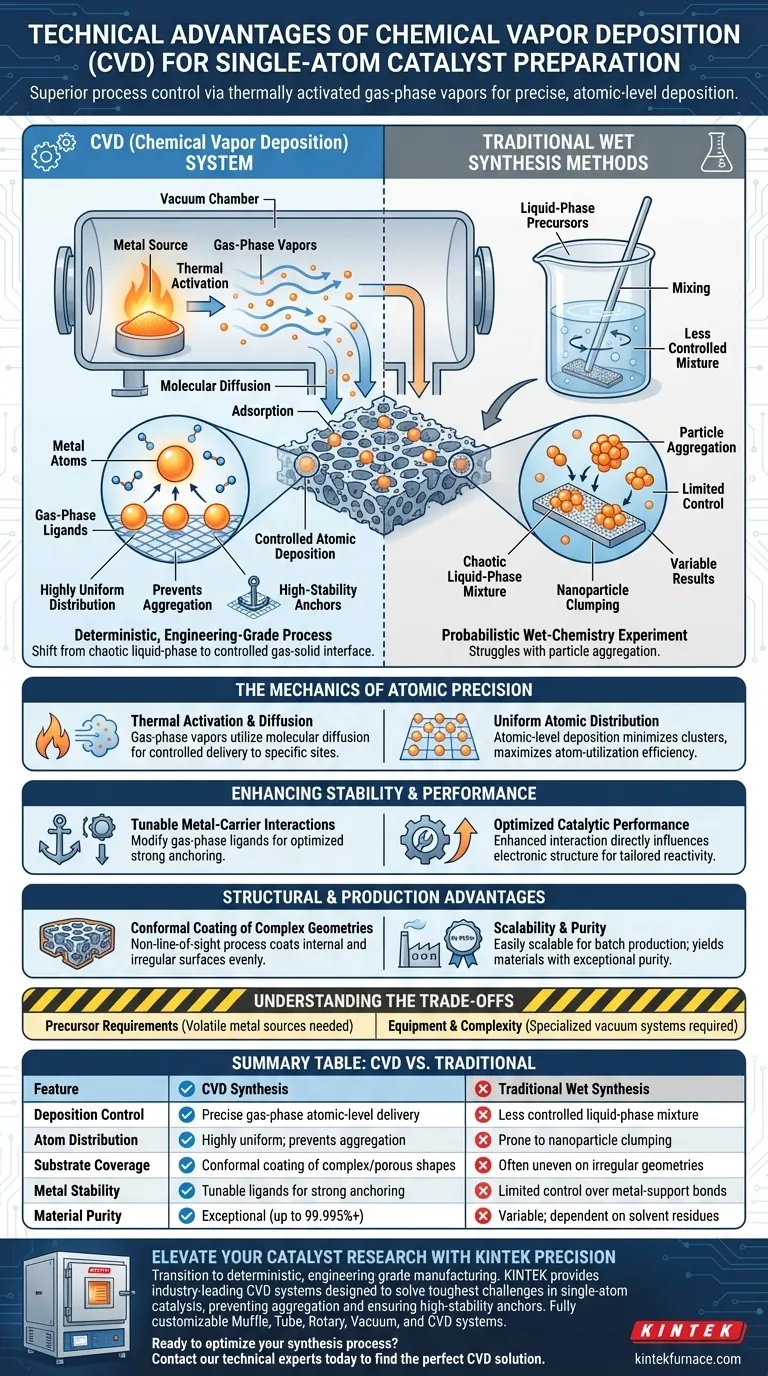

The primary technical advantage of Chemical Vapor Deposition (CVD) for single-atom catalyst preparation lies in its superior process control, which utilizes thermally activated gas-phase vapors to achieve precise, atomic-level deposition. Unlike traditional wet synthesis methods that often struggle with particle aggregation, CVD leverages molecular diffusion and adsorption to ensure a highly uniform distribution of individual metal atoms on a carrier.

Core Takeaway CVD fundamentally shifts synthesis from a chaotic liquid-phase mixture to a controlled gas-solid interface interaction. By manipulating gas-phase ligands and thermal conditions, this method solves the two biggest challenges in single-atom catalysis: preventing metal atom aggregation and securing high-stability anchors between the metal and the substrate.

The Mechanics of Atomic Precision

Thermal Activation and Diffusion

Traditional methods often rely on liquid-phase precursors, where controlling the deposition rate and location is difficult.

CVD operates by thermally activating metal sources into gas-phase vapors. These vapors utilize molecular diffusion to reach the substrate, allowing for a more controlled delivery of metal species to specific sites on the carrier material.

Uniform Atomic Distribution

A critical failure point in single-atom catalysis is the tendency of atoms to clump together (aggregate) into nanoparticles, losing their specific catalytic properties.

The CVD process enables atomic-level deposition, ensuring that metal atoms are distributed uniformly across the carrier. This precision minimizes the formation of clusters and maximizes the atom-utilization efficiency of the expensive metal catalysts.

Enhancing Stability and Performance

Tunable Metal-Carrier Interactions

The stability of a single-atom catalyst depends heavily on how strongly the atom is "anchored" to its support.

CVD allows for the adjustment of gas-phase ligands during the process. By modifying these ligands, you can optimize the chemical interaction between the metal atom and the carrier.

Optimized Catalytic Performance

This enhanced interaction does more than just hold the atom in place; it directly influences the electronic structure of the catalyst.

The result is a catalyst with high stability under operating conditions and optimized performance characteristics tailored to specific chemical reactions.

Structural and Production Advantages

Conformal Coating of Complex Geometries

Catalyst supports often have complex, porous, or irregular shapes to maximize surface area.

Because CVD is a non-line-of-sight process involving gas reactants, it creates highly conformal films. It effectively coats internal surfaces and complex shapes that physical deposition methods (like PVD) or liquid methods might coat unevenly or miss entirely.

Scalability and Purity

For industrial applications, the transition from lab-scale synthesis to mass production is often a bottleneck.

CVD is an easily scalable process suitable for batch production. It yields materials with exceptional purity (often exceeding 99.995%), which is critical for maintaining the selectivity and activity of single-atom catalysts.

Understanding the Trade-offs

While CVD offers precision, it introduces complexities not found in traditional wet chemistry.

Precursor Requirements

The process relies on the ability to volatilize the metal source. This requires careful selection of precursors that are chemically compatible with the process and capable of stable sublimation, which can limit the range of usable metal sources compared to liquid methods.

Equipment and Complexity

CVD requires specialized vacuum or controlled-atmosphere equipment, making the initial setup more capital-intensive than simple wet impregnation setups. Furthermore, the handling of chemical byproducts requires robust safety and exhaust management systems.

Making the Right Choice for Your Goal

If you are deciding between CVD and traditional synthesis for your catalyst project, consider the following:

- If your primary focus is Maximizing Active Sites: CVD is the superior choice because its atomic-level deposition prevents aggregation, ensuring nearly 100% atom utilization.

- If your primary focus is Long-Term Stability: CVD is recommended due to the ability to tune gas-phase ligands for stronger metal-support anchoring.

- If your primary focus is Complex Substrate Geometry: CVD provides the necessary non-line-of-sight coverage to uniformly coat highly porous or irregular carrier materials.

Ultimately, CVD transforms single-atom catalysis from a probabilistic wet-chemistry experiment into a deterministic, engineering-grade manufacturing process.

Summary Table:

| Feature | CVD Synthesis | Traditional Wet Synthesis |

|---|---|---|

| Deposition Control | Precise gas-phase atomic-level delivery | Less controlled liquid-phase mixture |

| Atom Distribution | Highly uniform; prevents aggregation | Prone to nanoparticle clumping |

| Substrate Coverage | Conformal coating of complex/porous shapes | Often uneven on irregular geometries |

| Metal Stability | Tunable ligands for strong anchoring | Limited control over metal-support bonds |

| Material Purity | Exceptional (up to 99.995%+) | Variable; dependent on solvent residues |

Elevate Your Catalyst Research with KINTEK Precision

Transition from probabilistic experiments to deterministic, engineering-grade manufacturing. KINTEK provides industry-leading CVD systems designed to solve the toughest challenges in single-atom catalysis—from preventing metal aggregation to ensuring high-stability anchors.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements. Our high-temperature furnace solutions empower you to achieve 100% atom utilization and superior catalytic performance.

Ready to optimize your synthesis process? Contact our technical experts today to find the perfect CVD solution for your research.

Visual Guide

References

- Yuquan Yang, Jinlong Zheng. Preparation of Fe, Co, Ni-based single atom catalysts and the progress of their application in electrocatalysis. DOI: 10.20517/microstructures.2024.65

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the technical advantages of using an LPCVD system for WS2-MoS2? Achieve Atomic Seamless Precision

- What types of materials can be deposited using CVD? Explore Versatile Thin Films for Advanced Applications

- What are the basic principles of CVD? Master Thin Film Deposition for Advanced Materials

- What is the function of the high-purity quartz furnace tube in LP-CVD? Enhance Your SLG Synthesis Quality

- Why is the placement of the selenium ceramic boat critical in CVD synthesis? Master Vapor Flux & Morphology

- What are the benefits of using a CVD furnace? Achieve Atomic-Level Control for Superior Thin Films

- What is the role of the Quartz Tube CVD Furnace in the synthesis of 2D In2Se3 nanosheets? Expert Synthesis Guide

- What role do CVD furnaces play in optics? Enhance Optical Performance with Precision Coatings