The primary steps in sintering dental zirconia involve a precisely controlled thermal cycle inside a specialized furnace. This cycle consists of a gradual heating stage to prevent thermal shock, a dwell (or soaking) stage where the material is held at a peak temperature (typically between 1300°C and 1600°C) to achieve densification, and a slow, controlled cooling stage to ensure the final restoration is stable and crack-free.

Sintering is not merely heating; it is a transformative process that converts a soft, chalk-like zirconia milling block into a dense, high-strength ceramic restoration. Mastering the variables of this thermal cycle is fundamental to achieving the desired clinical outcome.

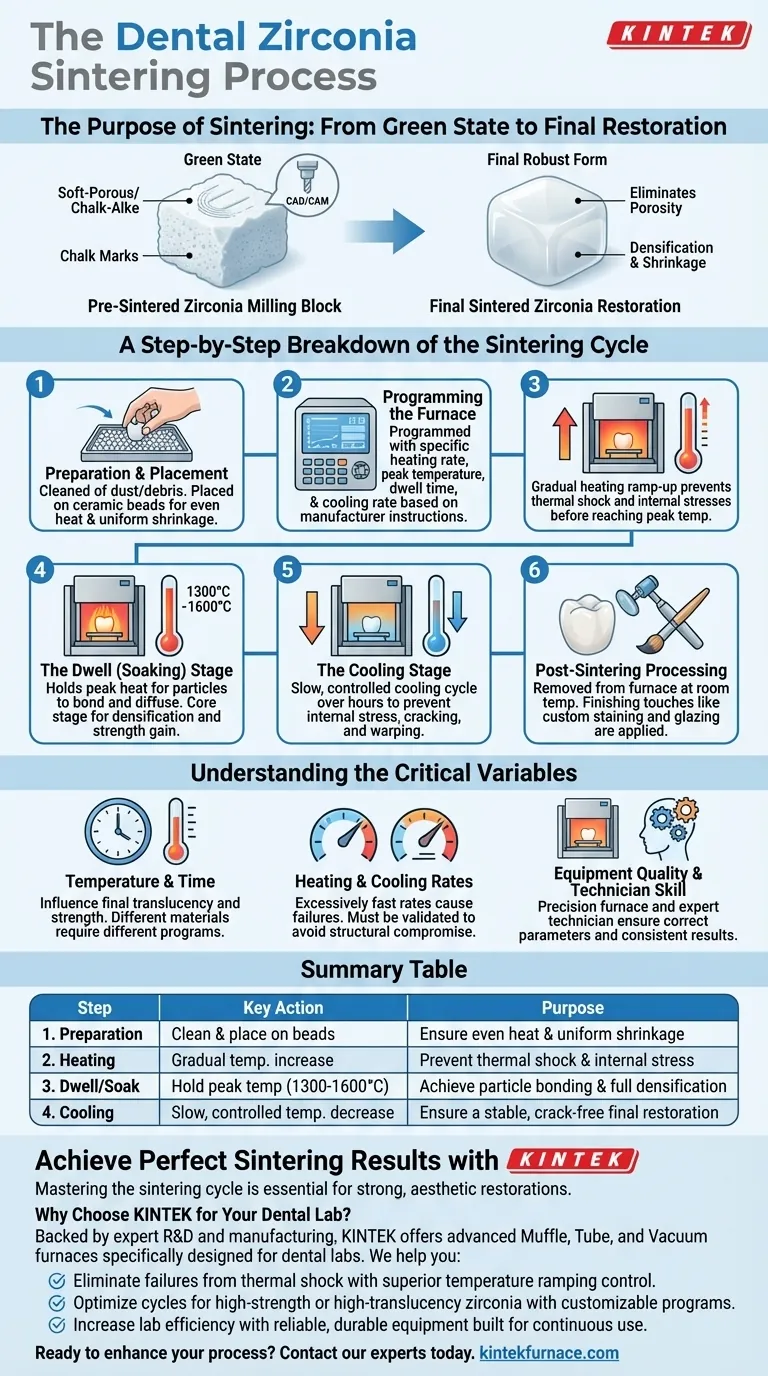

The Purpose of Sintering in Dentistry

Before a dental restoration is sintered, it exists in a "pre-sintered" or "green" state. In this form, the zirconia is soft and easy to mill with high precision using CAD/CAM technology.

However, this pre-sintered material lacks the necessary strength and durability for clinical use. The sintering process is what fuses the individual zirconia particles together, eliminating porosity and causing the material to shrink and densify into its final, robust form.

A Step-by-Step Breakdown of the Sintering Cycle

The entire process is managed by a programmable furnace, with each stage playing a critical role in the final quality of the restoration.

Step 1: Preparation and Placement

The milled zirconia restoration is first carefully cleaned of any dust or debris. It is then placed into the sintering furnace, often on a bed of ceramic beads or a specialized tray to ensure even heat distribution and allow for uniform shrinkage.

Step 2: Programming the Furnace

The dental technician programs the specific sintering cycle based on the zirconia manufacturer's instructions. Key parameters include the heating rate, peak temperature, dwell time (how long it stays at peak temperature), and the cooling rate.

Step 3: The Heating Stage

The furnace begins to heat up gradually. A slow and steady temperature ramp-up is essential to prevent thermal shock, which could introduce internal stresses and cause fractures in the material before it even reaches its peak temperature.

Step 4: The Dwell (Soaking) Stage

Once the furnace reaches the target temperature, it enters the dwell stage. It holds this peak heat for a specified duration, allowing the zirconia particles to bond and diffuse into one another. This is the core stage where densification occurs and the material gains its strength.

Step 5: The Cooling Stage

After the dwell time is complete, a controlled cooling cycle begins. This is arguably as critical as the heating stage. Cooling the zirconia too quickly will create internal stress, leading to a brittle restoration that is prone to cracking or warping. A slow cool-down over several hours is standard.

Step 6: Post-Sintering Processing

Once the restoration has cooled to room temperature, it is removed from the furnace. At this point, it has reached its final size, strength, and shade. It may then undergo finishing touches, such as custom staining and glazing, to achieve the final desired esthetics before being polished.

Understanding the Critical Variables

The success of a zirconia restoration is not guaranteed simply by owning a furnace. The outcome is highly dependent on controlling the variables of the process.

The Role of Temperature and Time

The final properties of the zirconia, including its translucency and strength, are directly influenced by the peak temperature and dwell time. Different zirconia formulations (e.g., high-strength vs. high-translucency) require different programs to optimize their intended characteristics.

The Impact of Heating and Cooling Rates

Rushing the process by using excessively fast heating or cooling rates is a primary cause of failures. While faster cycles exist, they must be validated for the specific material being used to avoid compromising the structural integrity and longevity of the restoration.

Equipment Quality and Technician Skill

The precision and reliability of the sintering furnace are paramount. Equally important is the expertise of the technician operating it. Their understanding of the materials and process ensures that the correct parameters are chosen and that the equipment is properly maintained for consistent results.

Making the Right Choice for Your Goal

The ideal sintering cycle depends directly on the clinical and aesthetic requirements of the final restoration.

- If your primary focus is maximum strength and durability: A longer, more conventional sintering cycle with a carefully controlled cool-down is typically the safest approach to ensure complete and stable densification.

- If your primary focus is high translucency for anterior restorations: Follow the manufacturer's specific firing parameters, as these are often fine-tuned to achieve the best optical properties without compromising strength.

- If your primary focus is laboratory efficiency: Utilize validated fast-sintering cycles and materials designed specifically for them, but be aware of the potential trade-offs in marginal stability or long-term performance.

Ultimately, mastering the sintering process is about precisely controlling a thermal journey to unlock the full potential of modern dental zirconia.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Clean and place restoration on ceramic beads | Ensure even heat distribution and uniform shrinkage |

| 2. Heating | Gradual temperature increase | Prevent thermal shock and internal stress |

| 3. Dwell/Soak | Hold at peak temperature (1300-1600°C) | Achieve particle bonding and full densification |

| 4. Cooling | Slow, controlled temperature decrease | Ensure a stable, crack-free final restoration |

Achieve Perfect Sintering Results with KINTEK

Mastering the sintering cycle is essential for producing strong, aesthetic, and long-lasting dental zirconia restorations. The precision of your furnace directly impacts your success.

Why Choose KINTEK for Your Dental Lab?

Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, and Vacuum furnaces specifically designed for the demanding requirements of dental laboratories. Our furnaces provide the precise temperature control and uniform heating necessary for consistent, high-quality results across all zirconia materials.

We help you:

- Eliminate failures caused by thermal shock with superior temperature ramping control.

- Optimize cycles for high-strength or high-translucency zirconia with customizable programs.

- Increase lab efficiency with reliable, durable equipment built for continuous use.

Ready to enhance your sintering process and the quality of your final restorations? Contact our experts today to find the perfect furnace solution for your unique needs.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations