In modern restorative dentistry, dental zirconia is a high-performance ceramic primarily used to fabricate durable and aesthetic crowns, bridges, and dental implants. The key to unlocking its superior properties lies in sintering, a precision-controlled heating process in a specialized furnace that transforms the pre-shaped material into its final, dense, and high-strength state.

Sintering is not merely a heating step; it is the critical transformation that unlocks zirconia's unique combination of clinical strength and natural aesthetics, making it a cornerstone material for modern dental restorations.

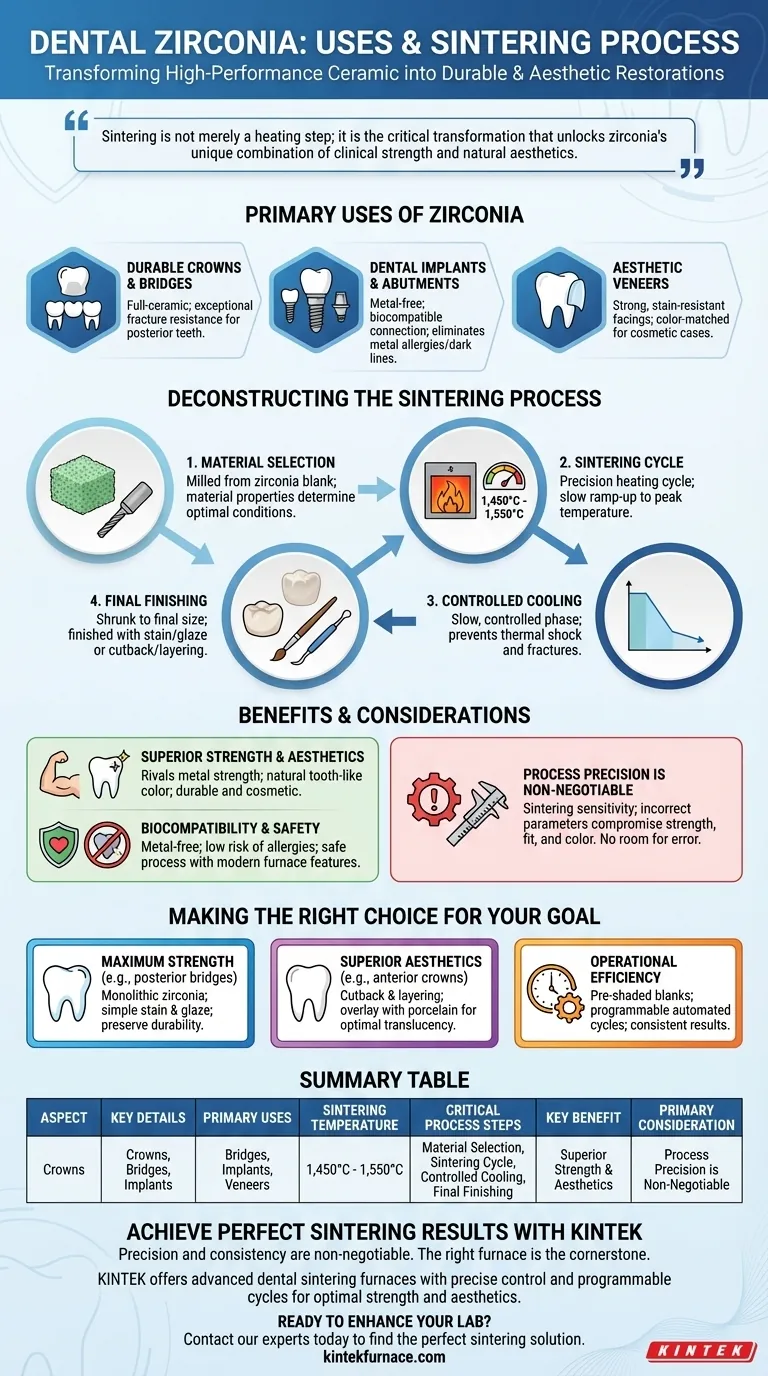

The Role of Zirconia in Dental Restorations

Zirconia's combination of biocompatibility, strength, and appearance makes it suitable for a wide range of applications, replacing both traditional metal and other ceramic-based restorations.

Creating Durable Crowns and Bridges

The most common use for sintered zirconia is in creating full-ceramic crowns and multi-unit bridges. Its exceptional fracture resistance makes it an ideal choice for posterior teeth that endure significant chewing forces.

The Foundation for Dental Implants

Zirconia is also used to manufacture dental implants and abutments (the connectors between the implant and the crown). This provides a metal-free alternative that eliminates the risk of metal allergies and dark lines at the gumline.

Aesthetic Solutions with Veneers

For cosmetic cases demanding high-quality results, zirconia can be used for veneers. It provides a strong, durable, and stain-resistant facing for teeth that can be colored to perfectly match the surrounding dentition.

Deconstructing the Sintering Process

The sintering process is a multi-stage procedure that requires precision at every step to achieve a clinically acceptable and durable final product.

Step 1: Material Selection and Analysis

The process begins with selecting the appropriate zirconia blank. The dental restoration is milled from this blank in an enlarged, porous "green state." The specific material properties determine the optimal sintering conditions.

Step 2: The Sintering Cycle

The milled restoration is placed in a sintering furnace. The furnace follows a highly specific, pre-programmed heating cycle, slowly raising the temperature to its peak—often between 1,450°C and 1,550°C.

Step 3: Controlled Cooling

After holding the peak temperature for a set duration, the furnace begins a slow, controlled cooling phase. This gradual temperature reduction is critical to prevent thermal shock, which could cause fractures or internal stresses in the material.

Step 4: Final Finishing

Once cooled, the restoration has shrunk to its final intended size and achieved its full strength. It is then finished using techniques like stain and glaze for a natural look, or more advanced cutback and layering methods where porcelain is added for superior aesthetics.

Understanding the Benefits and Considerations

While zirconia offers significant advantages, its success is entirely dependent on the precision of the manufacturing and sintering process.

The Benefit: Superior Strength and Aesthetics

Sintered zirconia provides a powerful combination of strength that rivals metal and a natural tooth-like color. This allows for restorations that are both durable enough for long-term function and cosmetically pleasing.

The Benefit: Biocompatibility and Safety

As a metal-free material, zirconia eliminates the risk of metal allergies. The process involves low radiation and modern furnaces are equipped with safety features like automatic shut-offs and temperature limiters to ensure a safe and predictable outcome.

The Consideration: Process Precision is Non-Negotiable

The primary trade-off is the process's sensitivity. Incorrect heating rates, peak temperatures, or cooling cycles can compromise the final strength, fit, and color of the restoration. There is no room for error in the sintering protocol.

Making the Right Choice for Your Goal

The final finishing technique applied after sintering should align directly with the clinical objective for the restoration.

- If your primary focus is maximum strength (e.g., posterior bridges): A monolithic (full-contour) zirconia restoration with a simple stain and glaze technique is the best approach to preserve its inherent durability.

- If your primary focus is superior aesthetics (e.g., anterior crowns): Utilize a cutback and layering technique, where the sintered zirconia core is overlaid with porcelain to achieve optimal translucency and a natural appearance.

- If your primary focus is operational efficiency: Leverage pre-shaded zirconia blanks and furnaces with programmable, automated cycles to ensure consistent, high-quality results with minimal manual intervention.

Ultimately, mastering the zirconia sintering process empowers dental professionals to deliver restorations that are as strong and reliable as they are aesthetically pleasing.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Uses | Crowns, Bridges, Implants, Veneers |

| Sintering Temperature | 1,450°C - 1,550°C |

| Critical Process Steps | Material Selection, Sintering Cycle, Controlled Cooling, Final Finishing |

| Key Benefit | Superior Strength & Aesthetics |

| Primary Consideration | Process Precision is Non-Negotiable |

Achieve Perfect Sintering Results with KINTEK

Precision and consistency in the sintering process are non-negotiable for creating strong, aesthetic dental restorations. The right furnace is the cornerstone of your success.

Backed by expert R&D and manufacturing, KINTEK offers advanced dental sintering furnaces with precise temperature control and programmable cycles to ensure your zirconia crowns, bridges, and implants achieve optimal strength and aesthetics every time.

Ready to enhance your lab's capabilities? Contact our experts today to find the perfect sintering solution for your unique needs.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations