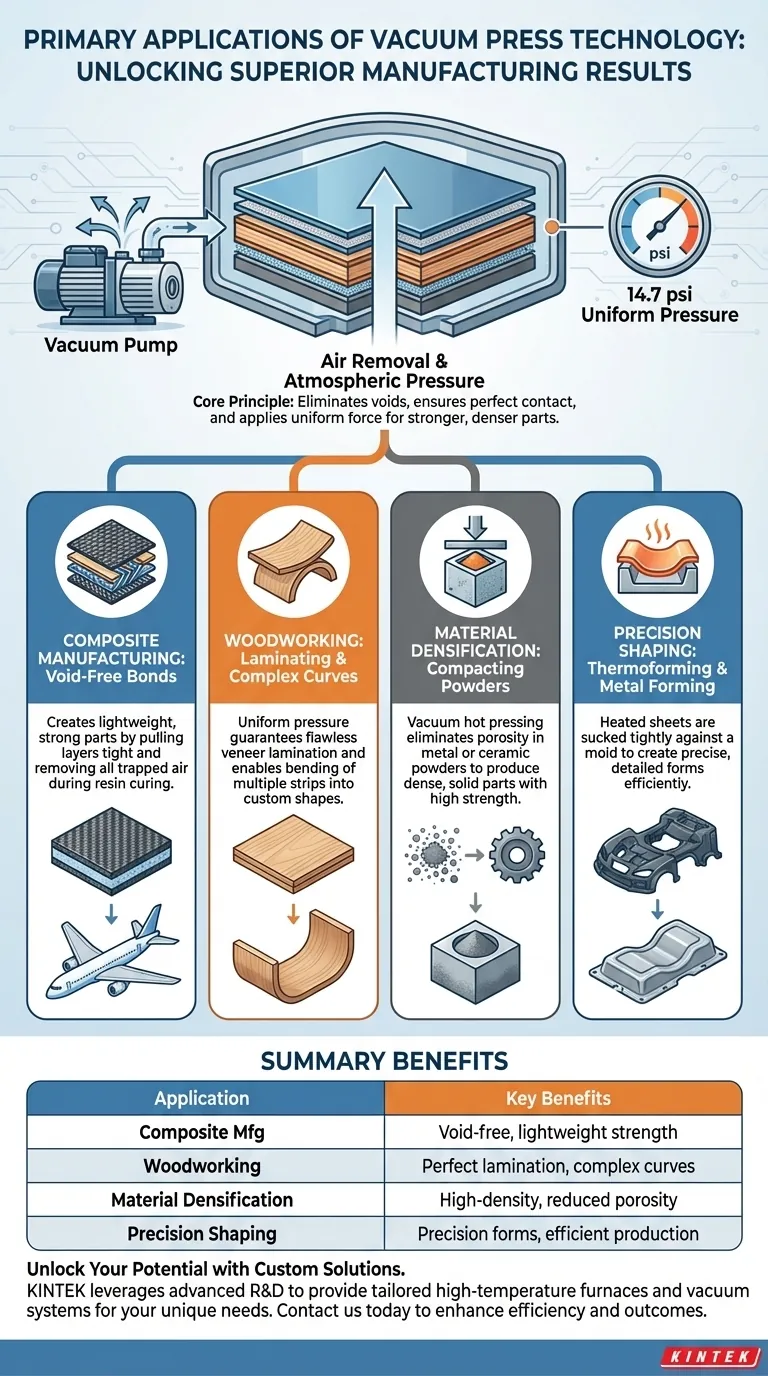

At its core, a vacuum press has four primary applications across modern industry. These include the lamination and forming of materials in woodworking, the consolidation and bonding of high-performance composites, the densification of powders into solid parts, and the precise shaping of advanced polymers and metals.

The crucial insight is that a vacuum press does more than just clamp materials together. By removing air, it leverages uniform atmospheric pressure to eliminate voids, prevent contamination, and force materials into perfect contact, resulting in parts that are stronger, denser, and more precisely formed than those made with mechanical pressure alone.

How Vacuum Transforms Manufacturing Processes

A vacuum press is not simply a press that operates in a vacuum. The technology's true value comes from manipulating the environment to achieve specific material outcomes.

The Fundamental Principle: Removing Air

The first and most critical function is the evacuation of air from between layers of material or from within a mold. This prevents air from becoming trapped, which would create voids, bubbles, or weak spots in the final product.

Removing air also eliminates atmospheric contaminants, such as oxygen and moisture, which can interfere with chemical processes like the curing of resins or cause oxidation in heated metals.

The Power of Atmospheric Pressure

Once a vacuum is pulled inside a sealed bag or chamber, the air pressure outside the bag—approximately 14.7 pounds per square inch (psi) at sea level—exerts a perfectly uniform force on every part of the surface.

This atmospheric pressure acts as a massive, perfectly distributed clamp. Unlike a mechanical clamp that applies pressure only at specific points, a vacuum press ensures that every square inch of the material receives the exact same amount of force.

Key Applications in Detail

The principles of air removal and uniform pressure are applied differently depending on the industry and material.

Composite Manufacturing: Creating Void-Free Bonds

In aerospace and automotive manufacturing, layers of materials like carbon fiber or fiberglass are saturated with a resin. A vacuum is used to pull the "stack" of layers together tightly.

This process, known as vacuum bagging, removes all trapped air between the plies and ensures the resin is distributed completely. The result is a lightweight, incredibly strong, and structurally solid composite part with no internal weaknesses.

Woodworking: Laminating and Forming Complex Curves

For woodworkers, a vacuum press is the ultimate tool for laminating veneers onto a substrate. The uniform pressure guarantees a perfect bond across the entire surface, with no bubbles or unglued spots.

It is also used to bend wood. By laminating multiple thin, glue-covered strips of wood around a form inside a vacuum bag, the atmospheric pressure clamps them into a specific curve until the glue dries, creating a strong, custom-shaped component.

Material Densification: Compacting Powders

In advanced materials science, a process called vacuum hot pressing is used to turn metal or ceramic powders into dense, solid parts.

Powder is placed in a die, and the entire assembly is put under a vacuum and heated. The vacuum removes air from between the powder grains, and then a press compacts the material. This eliminates porosity, leading to a final part with superior density and strength.

Thermoforming and Metal Forming: Precision Shaping

Vacuum forming is a common high-volume process for shaping plastic sheets. The sheet is heated until pliable and then draped over a mold. A vacuum is pulled, sucking the sheet tightly against the mold to create a precise shape.

This same principle can be applied to thin, malleable metals for applications in consumer electronics or jewelry, where complex and detailed forms are required efficiently.

Understanding the Trade-offs and Limitations

While powerful, vacuum press technology is not a universal solution. It comes with specific constraints that are important to understand.

Pressure Limitations

A standard vacuum press is limited by atmospheric pressure. You cannot achieve more than ~14.7 psi of clamping force. While this is sufficient for many applications, it is significantly less than the thousands of psi a hydraulic press can deliver.

For processes requiring higher pressures, an autoclave is often used, which combines vacuum bagging with an externally pressurized and heated vessel.

Cycle Time and Equipment

Pulling a complete vacuum is not instantaneous. The time it takes to evacuate the air can add to the overall cycle time of a manufacturing process, making it slower than simple mechanical clamping for some applications.

The required equipment—including vacuum pumps, airtight bags or chambers, and sealing components—adds a layer of cost and complexity to the production setup.

Material Suitability

The effectiveness of a vacuum press is highly dependent on the materials being used. It is ideal for processes involving laminates, uncured resins, glues, and thermoplastics. It is less effective for forming thick, rigid materials that require immense force to reshape.

Making the Right Choice for Your Goal

To determine if vacuum technology is appropriate, you must align its capabilities with your primary objective.

- If your primary focus is creating strong, lightweight composite parts: Vacuum bagging is the industry standard for ensuring void-free construction and complete resin infusion.

- If your primary focus is laminating veneers or bending wood: A vacuum press provides unparalleled uniform clamping pressure for flawless adhesion and complex curves.

- If your primary focus is producing dense, non-porous ceramic or metal parts from powder: A vacuum hot press is a critical tool for eliminating internal porosity and maximizing material strength.

- If your primary focus is cost-effective, high-detail shaping of plastic sheets: Vacuum forming is an essential and highly efficient manufacturing method.

By understanding the core principle of using an airless environment to apply uniform pressure, you can effectively leverage vacuum technology to achieve superior manufacturing outcomes.

Summary Table:

| Application | Key Benefits |

|---|---|

| Composite Manufacturing | Void-free bonds, lightweight strength |

| Woodworking | Perfect lamination, complex curve forming |

| Material Densification | High-density parts, reduced porosity |

| Thermoforming & Metal Forming | Precision shaping, efficient production |

Unlock the full potential of vacuum press technology for your specific needs! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, enhancing efficiency and outcomes. Contact us today to discuss how we can support your projects with tailored solutions!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity