The primary advantages of Molybdenum Disilicide (MoSi2) heating elements are their ability to operate at extremely high temperatures, their exceptional lifespan, and their robust resistance to oxidation. This unique combination of properties makes them a superior choice for the most demanding industrial and research furnace applications where reliability and performance are paramount.

MoSi2 heating elements solve the core challenge of achieving and maintaining extreme heat in oxidizing environments. Their defining characteristic is the formation of a self-healing, protective silica layer that enables unmatched longevity and operational stability at temperatures where most other materials fail.

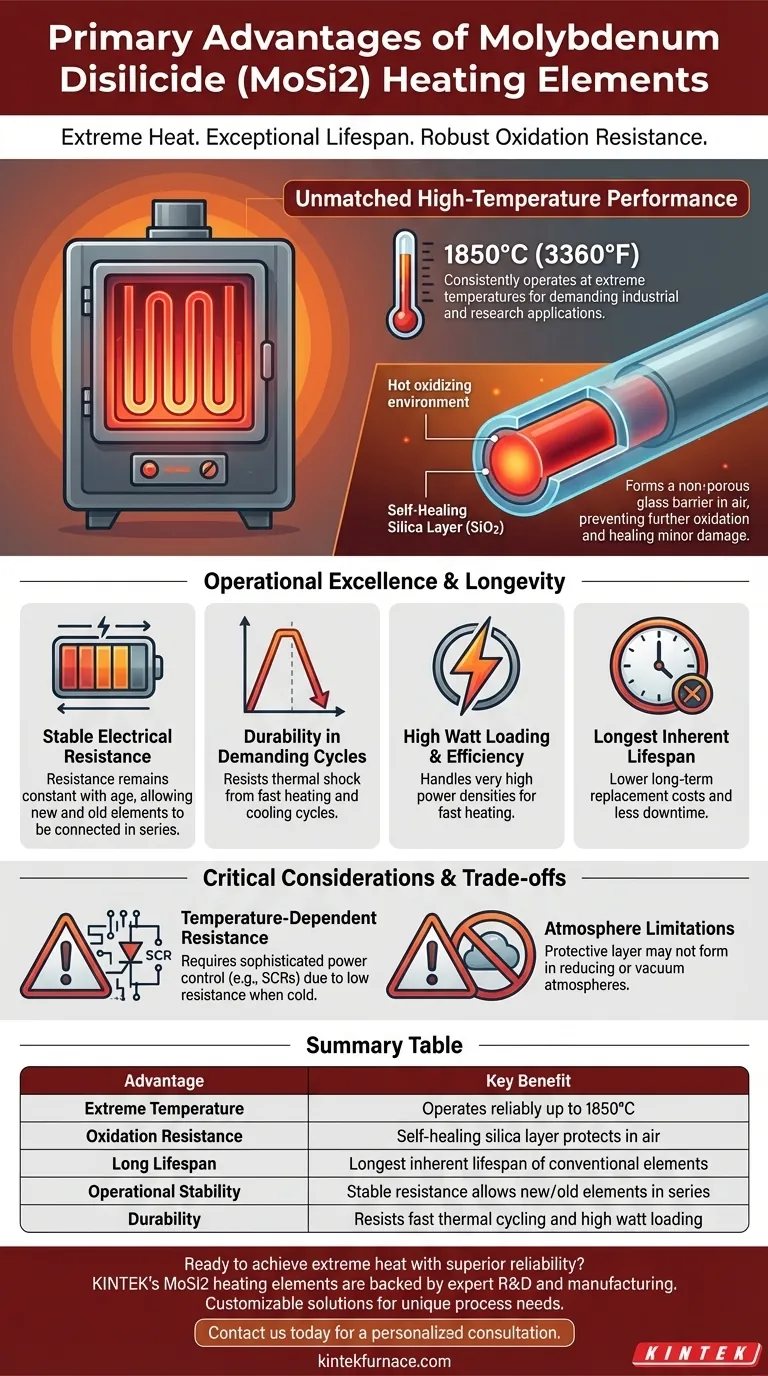

The Core Principle: Unmatched High-Temperature Performance

The fundamental value of MoSi2 elements is their ability to perform reliably under extreme thermal stress. This capability is rooted in their unique material science.

Reaching Extreme Temperatures

MoSi2 elements are engineered for the highest temperature applications. They can consistently operate at temperatures up to 1850°C (3360°F), far exceeding the limits of many other metallic or ceramic heating elements.

This makes them essential for processes like sintering advanced ceramics, growing crystals, and producing specialty glass and metals.

The Protective Silica Layer

The key to their durability in air is a remarkable chemical property. When heated in an oxidizing atmosphere, the element's surface forms a thin, non-porous layer of silica (SiO2), which is essentially glass.

This protective layer acts as a barrier, preventing further oxidation of the underlying material and effectively "healing" itself if minor surface damage occurs.

Operational Excellence and Longevity

Beyond pure temperature resistance, MoSi2 elements provide significant operational benefits that contribute to process efficiency and reduced downtime.

Stable Electrical Resistance

A key advantage is the stability of their electrical resistance over their long service life. This property is critically important for furnace design and maintenance.

Because the resistance does not change significantly with age, new and old elements can be connected in series without issue, simplifying replacement and ensuring uniform power distribution.

Durability in Demanding Cycles

These elements are highly resistant to the stress of fast thermal cycling. They can be heated and cooled rapidly without degrading, which is crucial for processes that require frequent temperature changes.

High Watt Loading and Efficiency

MoSi2 elements can handle very high power densities, or watt loadings. This allows for the design of furnaces that can heat up very quickly, improving throughput and operational efficiency.

The Longest Inherent Lifespan

Due to the protective silica layer and material stability, MoSi2 elements possess the longest inherent lifespan of all conventional electric heating elements, leading to lower long-term replacement costs and less furnace downtime.

Understanding the Trade-offs

While MoSi2 elements are superior in many respects, it is critical to understand their specific operational requirements to use them effectively.

The Challenge of Temperature-Dependent Resistance

The electrical resistance of MoSi2 changes significantly as its temperature increases. It has low resistance when cold and high resistance when hot.

This characteristic demands the use of sophisticated power control systems, typically using silicon-controlled rectifiers (SCRs), to manage the power delivery accurately and prevent overheating or damage during startup.

Atmosphere Limitations

The protective silica layer that is so beneficial in oxidizing atmospheres (like air) is their primary defense.

Using them in reducing or vacuum atmospheres can prevent this layer from forming or sustaining itself, potentially leading to accelerated degradation of the element.

How to Apply This to Your Process

Choosing a heating element depends entirely on the specific demands of your application.

- If your primary focus is achieving the highest possible temperatures in an air or oxygen-rich atmosphere: MoSi2 is the definitive choice for its unmatched thermal stability and oxidation resistance.

- If your primary focus is process consistency and rapid thermal cycling: The durability and stable resistance of MoSi2 elements ensure repeatable performance and a long service life.

- If your primary focus is minimizing long-term maintenance and downtime: The exceptionally long lifespan of MoSi2 elements makes them the most cost-effective solution for critical, high-use furnaces.

Ultimately, Molybdenum Disilicide elements provide a robust and reliable solution for achieving extreme heat where other materials simply cannot perform.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Extreme Temperature | Operates reliably up to 1850°C (3360°F) |

| Oxidation Resistance | Self-healing silica layer protects in air |

| Long Lifespan | Longest inherent lifespan of conventional elements |

| Operational Stability | Stable resistance allows new/old elements in series |

| Durability | Resists fast thermal cycling and high watt loading |

Ready to achieve extreme heat with superior reliability?

KINTEK's MoSi2 heating elements are backed by expert R&D and manufacturing, offering the unmatched high-temperature performance and longevity detailed above. Whether your application involves sintering advanced ceramics, crystal growth, or specialty glass production, our elements are engineered for the most demanding industrial and research furnace environments.

We provide:

- Customizable solutions for unique process needs.

- Support for Muffle, Tube, Rotary, Vacuum, and CVD furnace systems.

- Expert guidance to ensure optimal performance in your specific atmosphere.

Contact us today to discuss how our MoSi2 heating elements can enhance your high-temperature processes and reduce long-term costs. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness