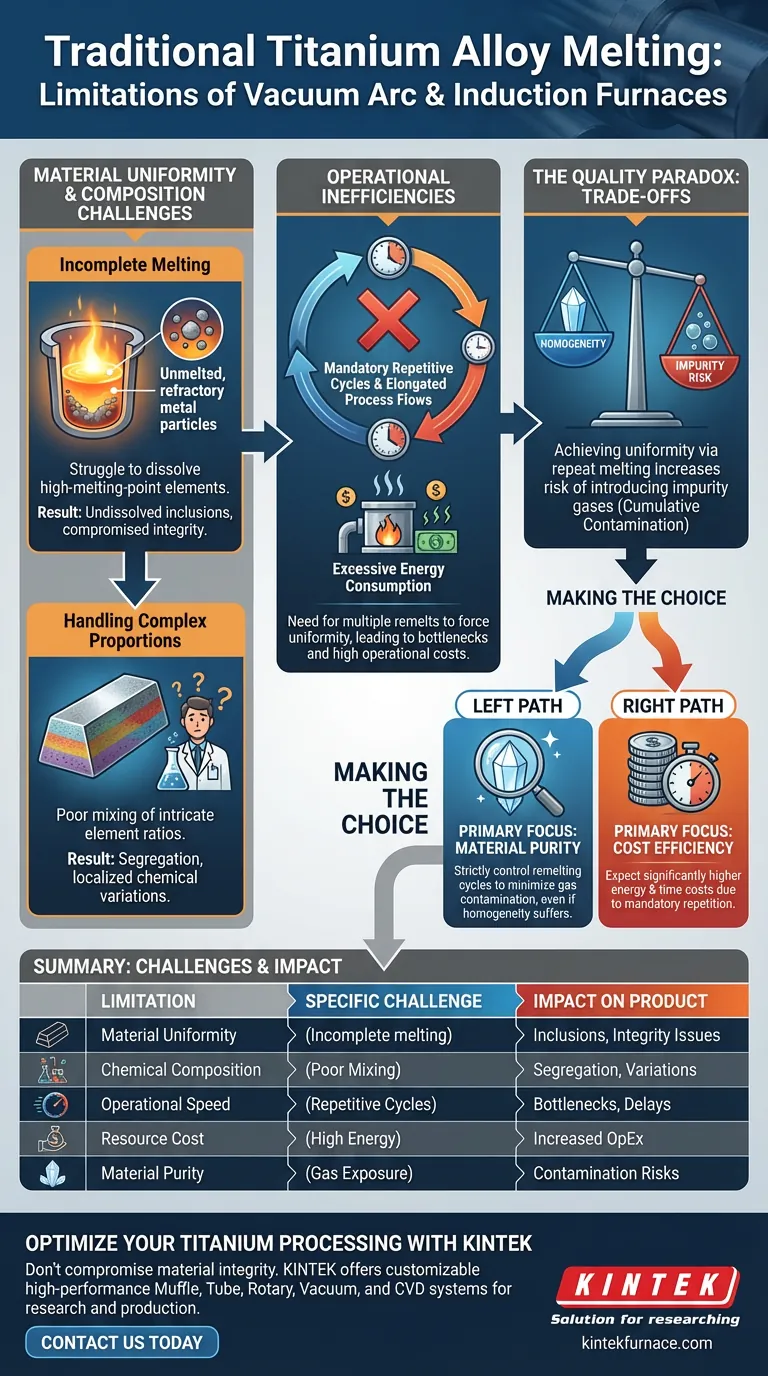

Traditional titanium alloy melting processes relying on vacuum consumable arc or induction furnaces face significant hurdles regarding efficiency and compositional uniformity. The primary limitations are the incomplete melting of high-melting-point elements and the inability to easily handle complex alloy proportions in a single pass.

The fundamental constraint is the need for repetitive processing to compensate for poor initial mixing. This results in a compounded problem: higher energy costs, longer production times, and a degradation of material purity due to gas exposure.

The Challenge of Compositional Uniformity

Incomplete Melting of Refractory Elements

The most critical technical limitation is the struggle to fully dissolve high-melting-point elements.

In a single pass, these furnaces often fail to generate the sustained, localized conditions necessary to completely melt these refractory components. This leaves undissolved inclusions in the alloy, compromising the structural integrity of the final material.

Handling Complex Proportions

Achieving a precise chemical balance is difficult when dealing with complex alloy proportions.

Standard arc and induction methods often lack the convective mixing capability needed to homogenize intricate element ratios in one go. This results in segregation, where different areas of the ingot possess different chemical properties.

Operational Inefficiencies

The Necessity of Repetitive Cycles

To counteract the issues of incomplete melting and segregation, manufacturers are forced to use multiple repeat melting cycles.

Operators cannot rely on a "one-and-done" melt; they must remelt the material several times to gradually force the alloy into a uniform state.

Elongated Process Flows

The requirement for multiple cycles drastically extends the process flow.

Production throughput is throttled because each batch occupies the furnace for significantly longer than a theoretical single-pass melt would require. This creates bottlenecks in the manufacturing timeline.

Excessive Energy Consumption

Repeatedly heating the same mass of metal to its melting point results in high energy consumption.

The energy efficiency of the total process drops precipitously with each required remelt, significantly increasing the operational cost per ton of titanium produced.

Understanding the Trade-offs: The Quality Paradox

The Risk of Impurity Introduction

A critical trade-off exists between achieving uniformity and maintaining purity.

While repeat melting helps homogenize the alloy, it simultaneously increases the risk of introducing impurity gases.

Cumulative Contamination

Every additional operational step exposes the melt to potential contamination sources.

Consequently, the very process used to fix the alloy's composition (remelting) can degrade its quality by introducing gaseous defects that are difficult to remove.

Making the Right Choice for Your Goal

When evaluating traditional vacuum arc or induction melting for titanium applications, you must account for the inevitable overhead required to ensure quality.

- If your primary focus is material purity: You must strictly control the number of remelting cycles to minimize the introduction of impurity gases, even if it challenges homogeneity.

- If your primary focus is cost efficiency: You must recognize that the energy consumption and time requirements will be significantly higher than expected due to the mandatory repetition of the melting process.

Success in traditional titanium melting requires balancing the need for chemical homogeneity against the escalating costs and contamination risks of repetitive processing.

Summary Table:

| Limitation Category | Specific Challenge | Impact on Final Product |

|---|---|---|

| Material Uniformity | Incomplete melting of refractory elements | Undissolved inclusions & compromised integrity |

| Chemical Composition | Poor convective mixing of complex ratios | Segregation and localized chemical variations |

| Operational Speed | Mandatory repetitive melting cycles | Production bottlenecks and elongated process flows |

| Resource Cost | High cumulative energy consumption | Increased operational costs per ton of material |

| Material Purity | Increased gas exposure during remelting | Higher risk of oxygen/nitrogen contamination |

Optimize Your Titanium Processing with KINTEK

Traditional melting bottlenecks shouldn't compromise your material integrity. At KINTEK, we understand the delicate balance between chemical homogeneity and purity. Backed by expert R&D and manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet the rigorous demands of titanium alloy research and production.

Stop settling for inefficient repeat cycles. Contact us today to discover how our advanced laboratory and industrial high-temperature furnaces can streamline your workflow, reduce energy waste, and deliver the material precision your unique needs deserve.

Visual Guide

References

- Yuhang Miao, Jinming Hu. Research Progress of Preparing Titanium Alloy By Molten Salt Method. DOI: 10.62051/ijnres.v2n1.30

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does sustainability play in the IGBT induction melting furnace market? A Key Driver for Modern Foundries

- Can aluminium be melted in an induction furnace? Discover the Efficient, High-Quality Method

- What is the primary role of a vacuum melting furnace in the production of aluminum-lithium alloys? Achieve High Purity

- What is the role of a vacuum induction furnace in CuNiSiCrCoTiNbx synthesis? Ensure Purity & Homogeneity

- How does a vacuum environment help in metal purification? Achieve High Purity and Enhanced Properties

- What is induction welding and how is it performed? Discover High-Speed, Non-Contact Welding for Metals and Plastics

- What is the primary function of a vacuum arc furnace in the production of Ti-6Al-7Nb alloys? Ensure Peak Material Purity

- Why is repeated melting and flipping of alloy ingots necessary? Achieving Homogeneity in Mn–Ni–Fe–Si Alloys