Yes, absolutely. Not only can aluminum be melted in an induction furnace, but it is a highly practical and often preferred method for industrial applications. The unique physics of induction heating offers significant advantages in speed, efficiency, and quality control when processing aluminum and its alloys.

The question is not if an induction furnace can melt aluminum, but why it is such an effective tool for the job. Its ability to generate heat directly within the metal provides a level of control and purity that conventional furnaces struggle to match.

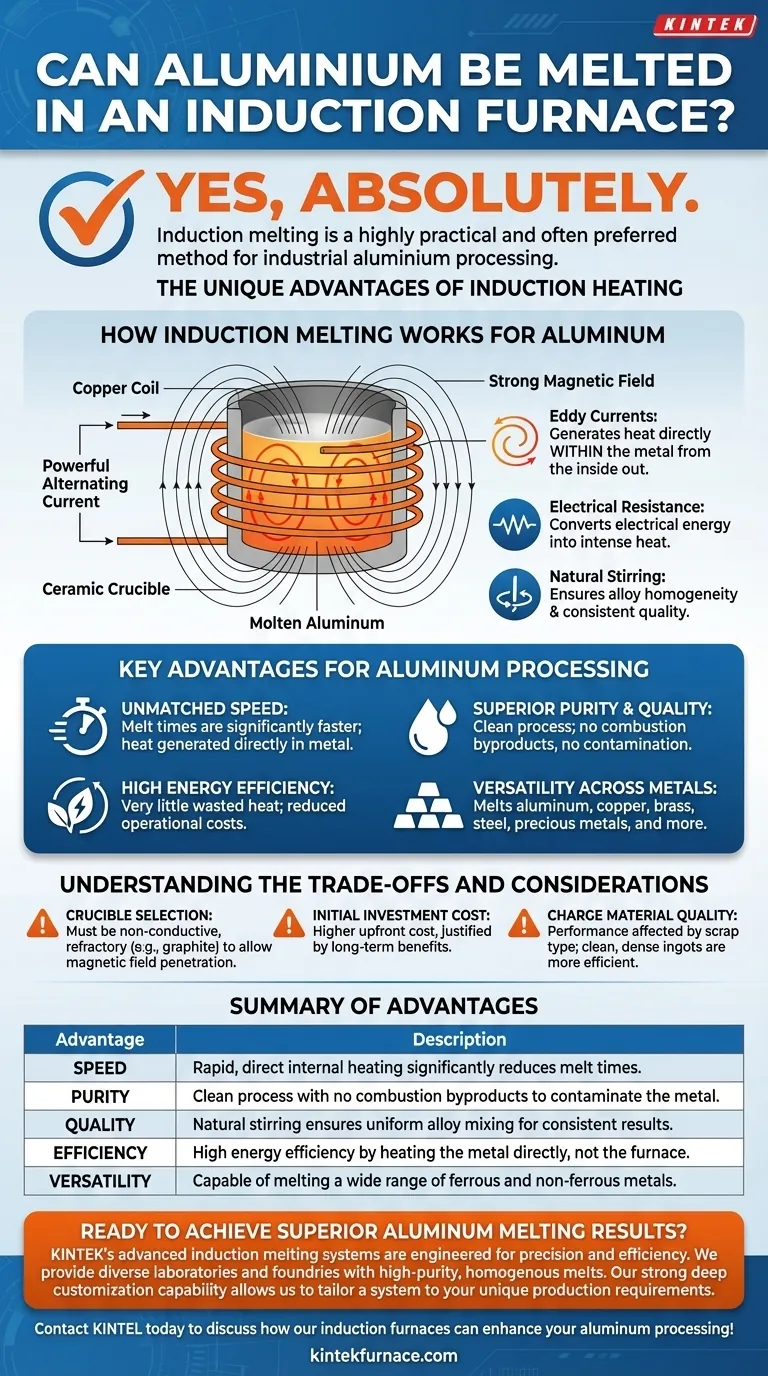

How Induction Melting Works for Aluminum

Induction melting is fundamentally different from fuel-fired or resistance furnaces. It does not heat the aluminum from the outside in; it generates heat from the inside out.

The Principle of Electromagnetic Induction

An induction furnace uses a powerful alternating current passed through a copper coil. This creates a strong, rapidly changing magnetic field around the crucible containing the aluminum. This magnetic field induces powerful electrical currents, known as eddy currents, directly within the aluminum charge.

The Role of Electrical Resistance

As these eddy currents flow through the aluminum, they encounter the metal's natural electrical resistance. This resistance converts the electrical energy into intense heat, causing the aluminum to melt quickly and efficiently.

Natural Stirring for Alloy Homogeneity

The powerful magnetic forces at play also create a natural stirring or "motor" effect within the molten metal. For aluminum alloys, this is a critical benefit, as it ensures all alloying elements are thoroughly and uniformly mixed, resulting in a consistent, high-quality final product.

Key Advantages for Aluminum Processing

Using an induction furnace for aluminum provides several distinct operational advantages over traditional methods.

Unmatched Speed

Because the heat is generated directly within the metal, melt times are significantly faster. There is no need to wait for a furnace chamber to heat up and then slowly transfer that heat to the charge. This leads to higher productivity and throughput.

Superior Purity and Quality

Induction is an exceptionally clean melting process. Since there is no combustion, byproducts like gas and soot cannot contaminate the molten aluminum. This results in a higher-purity melt, which is critical for many casting and manufacturing applications.

High Energy Efficiency

By heating the metal directly, very little energy is wasted heating the furnace walls or the surrounding atmosphere. This makes induction melting one of the most energy-efficient methods available, reducing long-term operational costs.

Versatility Across Metals

Induction furnaces are not limited to aluminum. Their versatility allows for the melting of a wide range of ferrous and non-ferrous metals, including copper, brass, steel, iron, and even precious metals like gold and silver.

Understanding the Trade-offs and Considerations

While highly effective, the decision to use an induction furnace involves understanding its specific requirements and limitations.

Crucible Selection is Paramount

The crucible, which holds the aluminum, must be made of a non-conductive, refractory material like graphite or a ceramic composite. It needs to allow the magnetic field to pass through it to reach the metal while being able to withstand the intense heat of molten aluminum.

Initial Investment Cost

Induction furnace systems typically have a higher upfront capital cost compared to simple gas-fired furnaces. This investment is often justified by lower long-term energy costs, higher productivity, and improved metal quality.

Charge Material Quality

While versatile, the performance of an induction furnace can be affected by the type of aluminum scrap being charged. Very fine, loose, or heavily oxidized scrap can be less efficient to melt than clean, dense ingots or solids.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on your operational priorities.

- If your primary focus is high-quality alloy production: The natural stirring action and clean heating of induction make it the ideal choice for ensuring metallurgical consistency.

- If your primary focus is speed and high throughput: The rapid melting cycles of an induction furnace offer a significant productivity advantage over conventional methods.

- If your primary focus is energy efficiency and environmental control: Induction's direct heating method minimizes energy waste and eliminates emissions from combustion, making it a cleaner and more cost-effective choice.

Ultimately, leveraging induction technology for aluminum provides a precise, clean, and efficient path to superior melting results.

Summary Table:

| Advantage | Description |

|---|---|

| Speed | Rapid, direct internal heating significantly reduces melt times. |

| Purity | Clean process with no combustion byproducts to contaminate the metal. |

| Quality | Natural stirring ensures uniform alloy mixing for consistent results. |

| Efficiency | High energy efficiency by heating the metal directly, not the furnace. |

| Versatility | Capable of melting a wide range of ferrous and non-ferrous metals. |

Ready to achieve superior aluminum melting results?

KINTEK's advanced high-temperature furnace solutions, including our robust induction melting systems, are engineered for precision and efficiency. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with the technology to ensure high-purity, homogenous melts.

Our strong deep customization capability allows us to tailor a system—whether it's a Muffle, Tube, Rotary, Vacuum, or Atmosphere Furnace—to meet your unique production requirements and operational goals.

Contact KINTEL today to discuss how our induction furnaces can enhance your aluminum processing!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity